A coal mine gas water pressure relief separator

A gas water and separator technology, which is applied in separation methods, liquid degassing, chemical instruments and methods, etc., can solve the problems of waste of manpower, blockage of drainage passages, and large manpower input.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation steps.

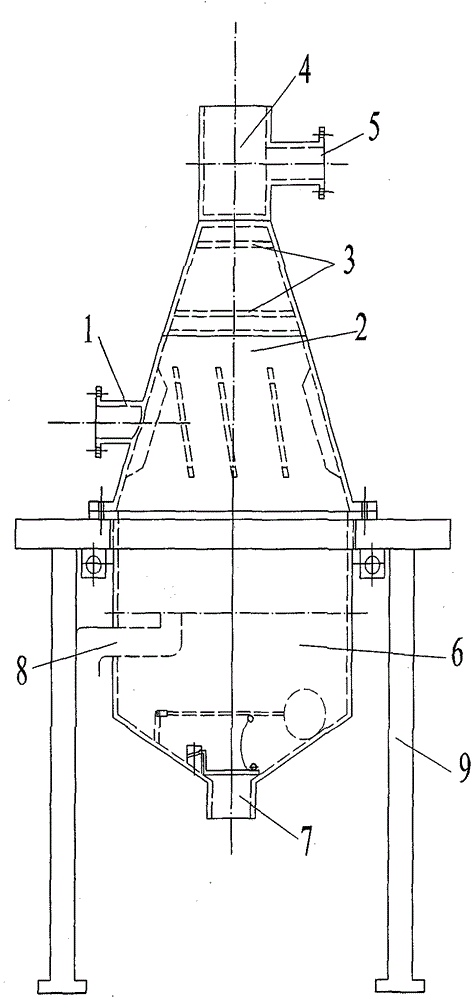

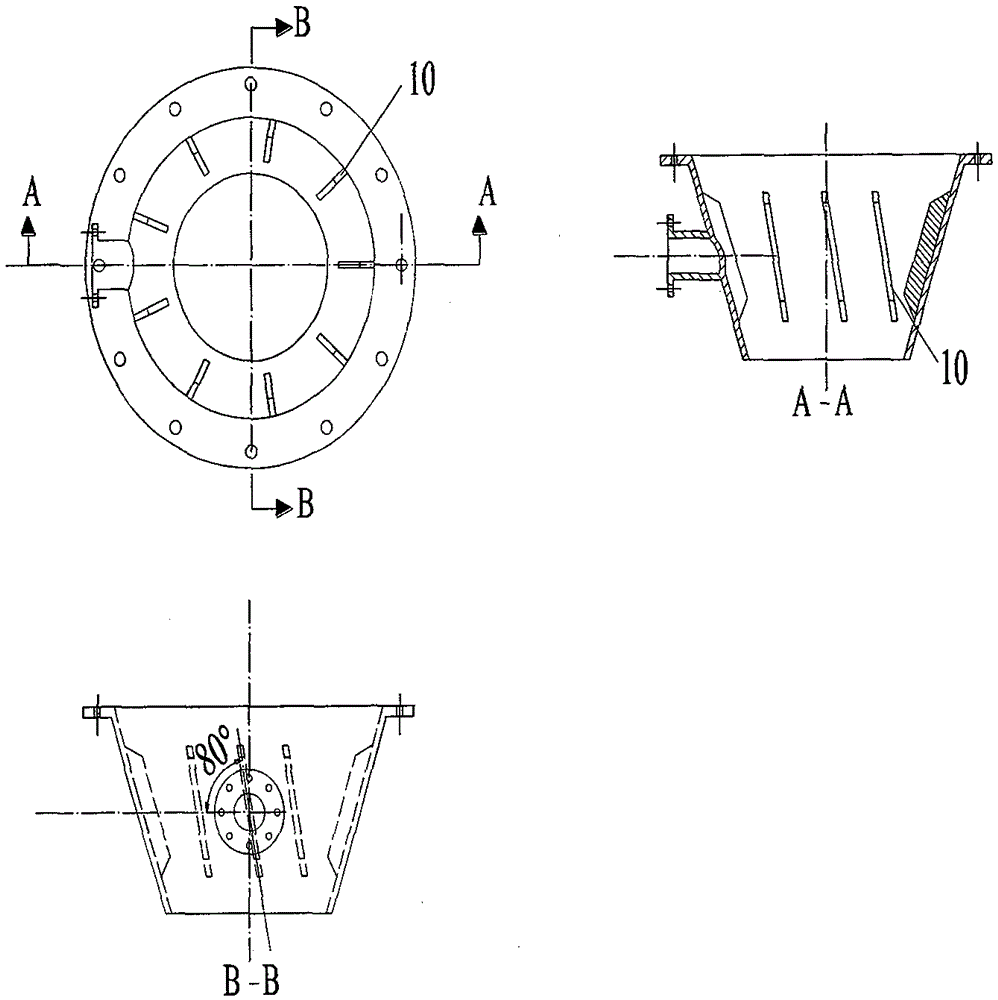

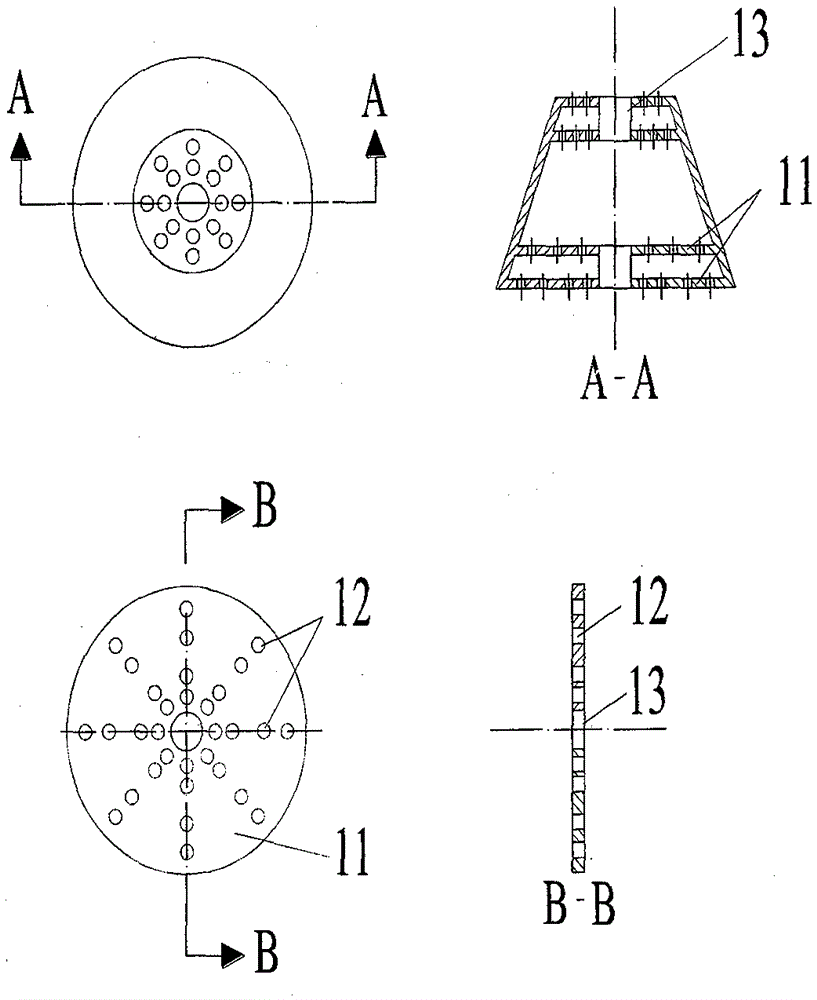

[0019] Structural schematic diagram of a coal mine gas water pressure relief separator ( figure 1 ), mainly including high-pressure gas-water mixture inlet pipe (1), screw pressure relief chamber (2), double-layer annular mesh water blocking plate (3), gas collection chamber (4), gas outlet (5), water collection It consists of a slag tank (6), an inverted cone cut-type automatic slag discharge outlet (7), an automatic overflow outlet (8), a support (9) and the like. After the hydraulic measure hole is filled with water, it is connected to the gas-water pressure relief separator through the inlet pipe (1), and the coal slime (rock slag), gas gas and water are sprayed into the gas-water separator under high pressure, and pass throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com