Adjustable tight pressing device for forming mill

A cold bending machine and top-adjusting technology, which is applied in the field of adjustable top tightening devices for cold bending machines, can solve the problems of labor consumption, time-consuming, and labor-intensive, and achieve the effects of smooth operation process, reasonable structure, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

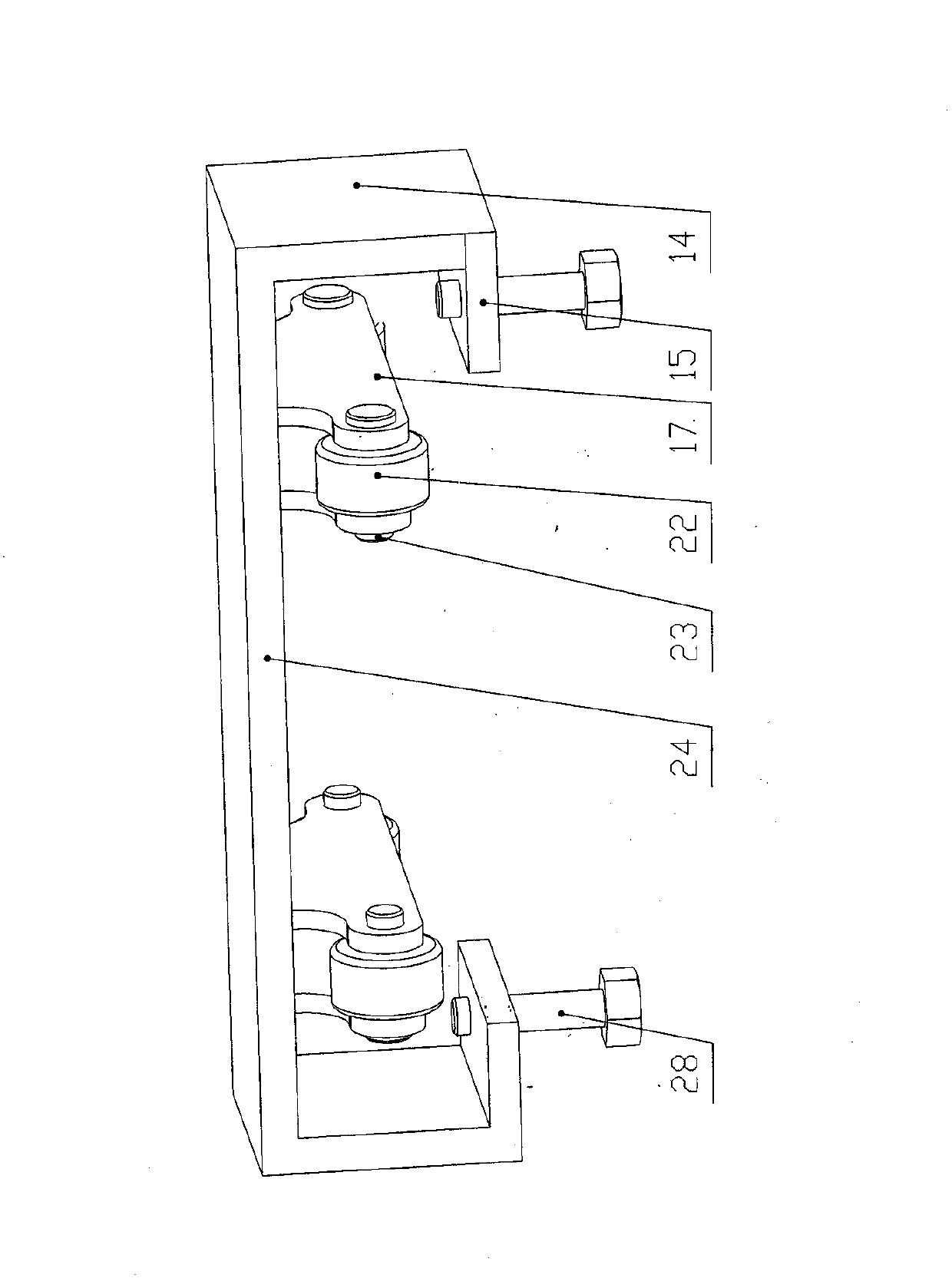

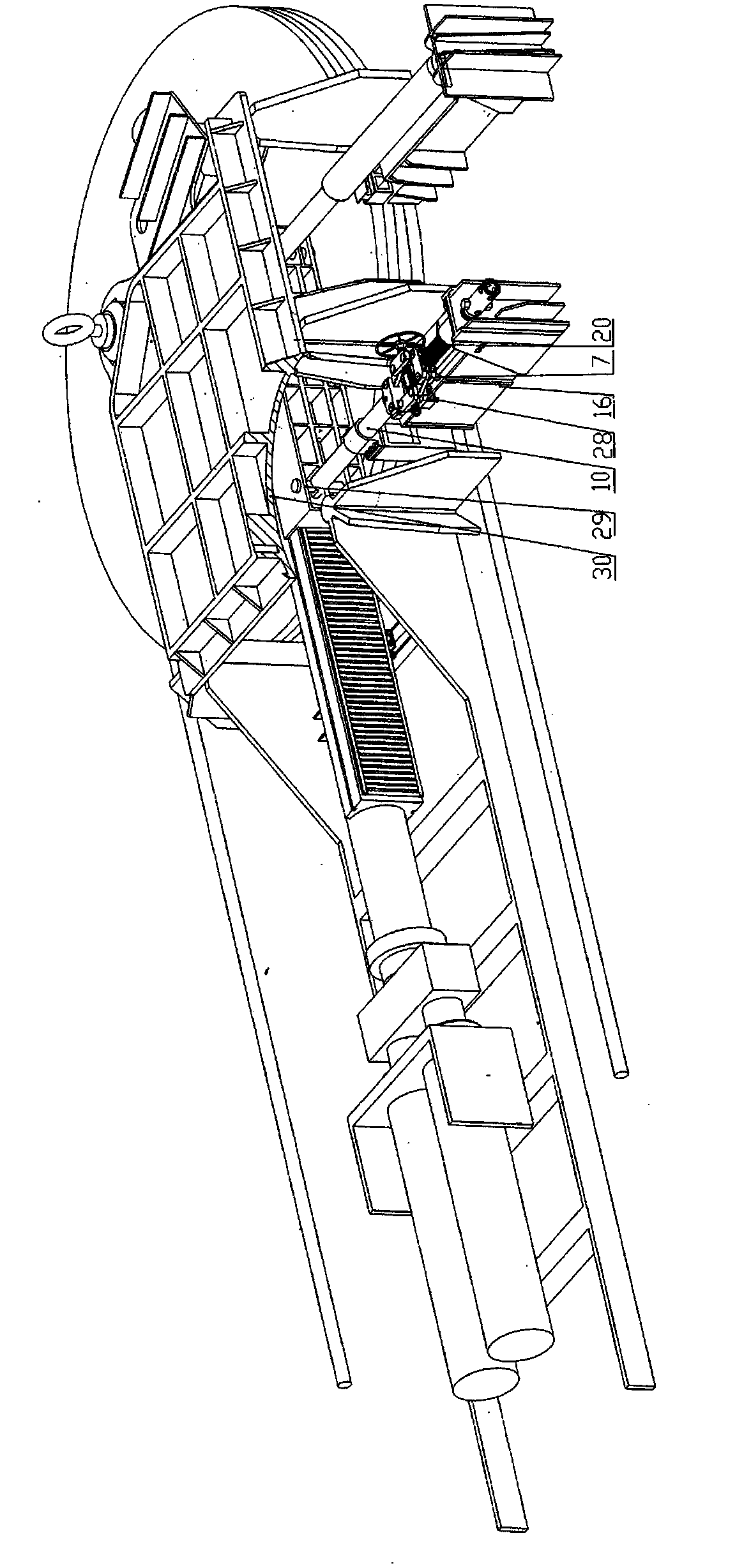

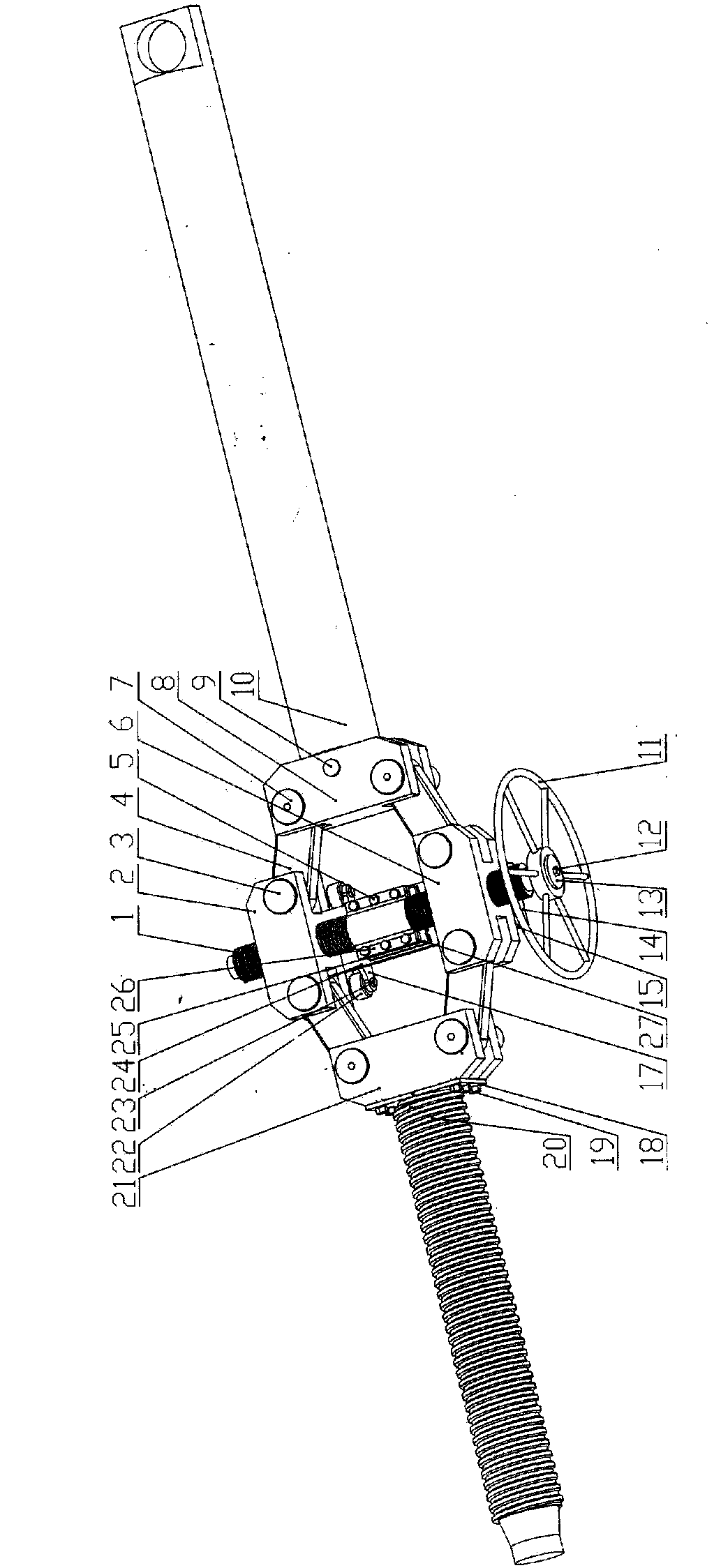

[0018] Such as figure 1 , 2 , 3, the present invention includes a hinge assembly, a pulley assembly, a hoop cover assembly and a handwheel assembly. Wherein one end of the split screw rod 1 of the hinge assembly assembly is connected to the hand wheel assembly, the middle part of the split screw rod 1 is arranged in the hoop sleeve assembly, and the split screw rod 1 can rotate in the hoop sleeve assembly, and the hoop sleeve The components in turn support the hinge assembly components. The hoop cover assembly is arranged on the connecting plate 24 of the pulley assembly, and the pulley assembly is arranged on the guide rail seat 16 for sliding to facilitate adjustment to a corresponding position. Support plate 14 is set under the connecting plate 24 of tackle assembly, and support plate 14 is provided with fixed plate 15, passes fixed plate 15 by fixed screw rod 28 and is fixed on the guide rail seat. The left and right threads provided at both ends of the split screw rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com