Gear milling cutter unit

A technology for milling cutters and gears, which is applied to gear tooth manufacturing devices, gear tooth manufacturing tools, belts/chains/gears, etc. It can solve the problems of lower workpiece quality, poor surface finish, and increased tool costs, and achieve machining dimensional accuracy High, good surface finish, and the effect of reducing equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the drawings and specific embodiments.

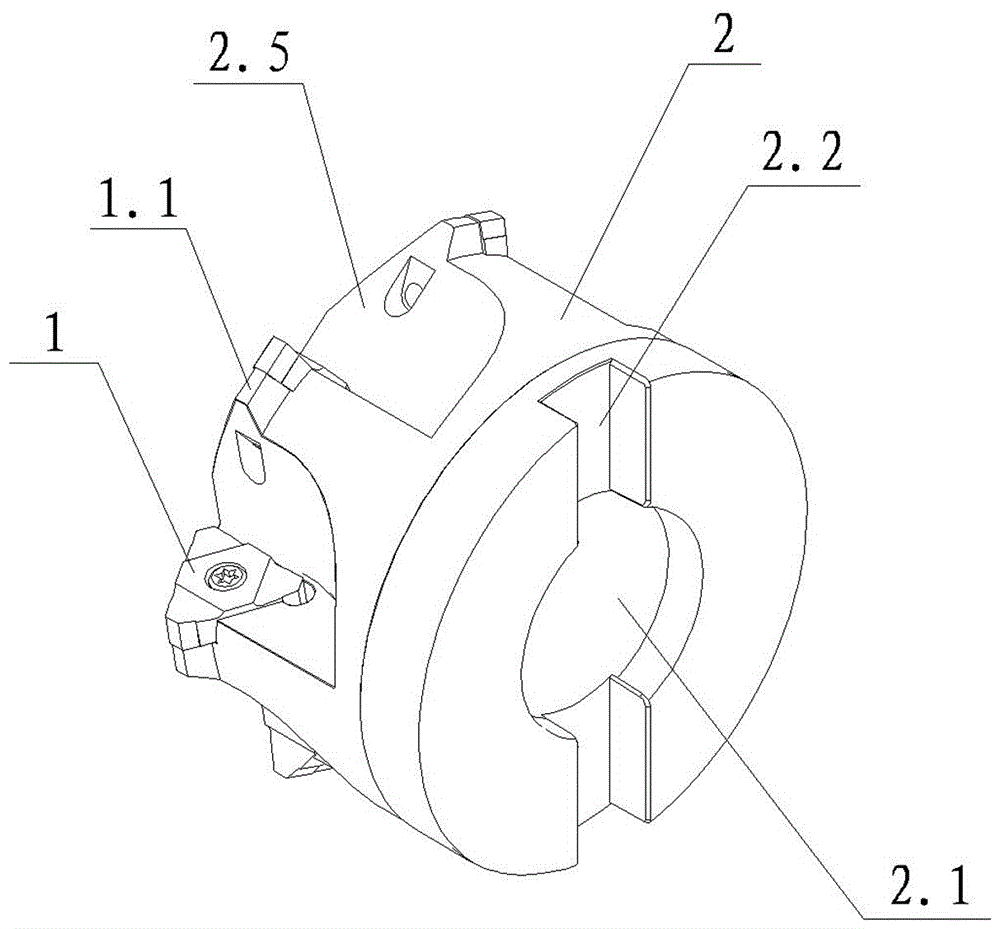

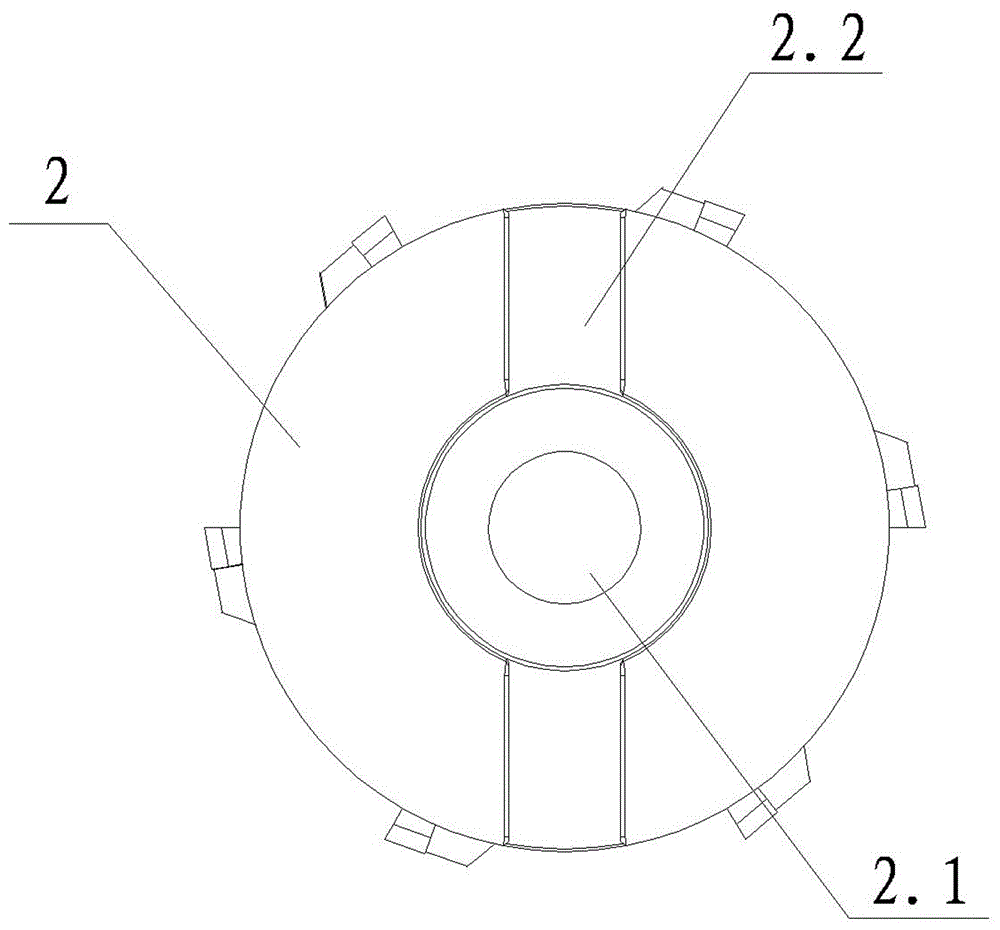

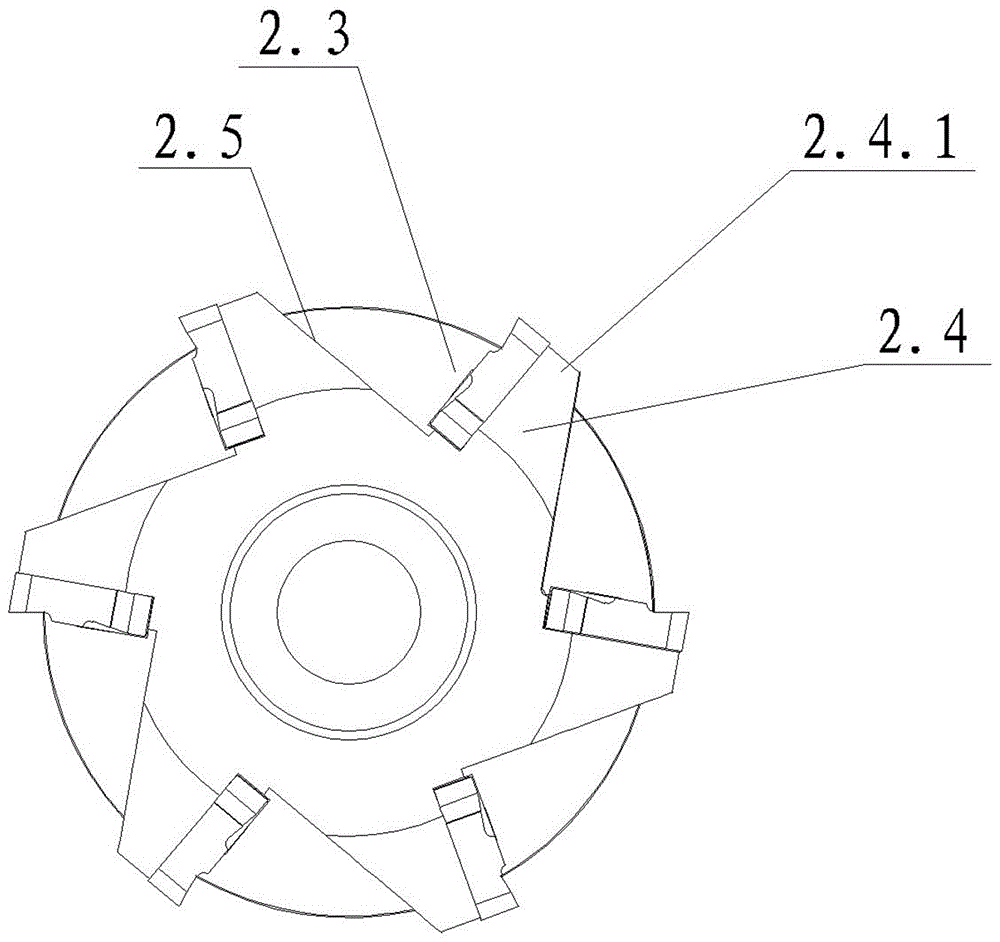

[0026] See figure 1 , figure 2 , image 3 and Figure 4 As shown, the gear milling cutter device of the present invention includes a blade 1 and a cutter head 2. The center of the cutter head 2 is provided with a drive shaft hole 2.1. A limit slot 2.2 is provided on the end surface of one end of the cutter head 2, and the limit slot 2.2 is in communication with the drive shaft hole 2.1. At least one knife slot 2.3 is cut radially inwardly on the circumferential surface of the cutter head 2. A blade seat 2.4 is provided on the side wall of the knife slot 2.3. The blade 1 is installed on the blade seat 2.4 and the cutter head 1.1 of the blade 1 is exposed outside the circumferential surface of the cutter head 2. The outer side wall of the blade seat 2.4 protrudes radially along the cutter head 2 to form an extension 2.4.1 for supporting the blade 1 cutter he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com