Saw blade installation auxiliary equipment of profile steel cold saw

A technology for installation assistance and saw blades, which is applied in the direction of hand-held tools and manufacturing tools, can solve problems such as danger, large volume and mass, and troublesome alignment and connection of saw blades and fixed disks, so as to improve labor efficiency and fast installation and connection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings.

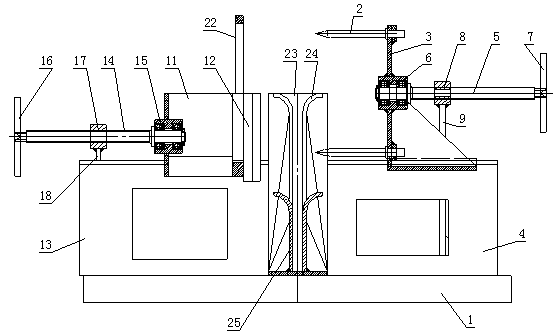

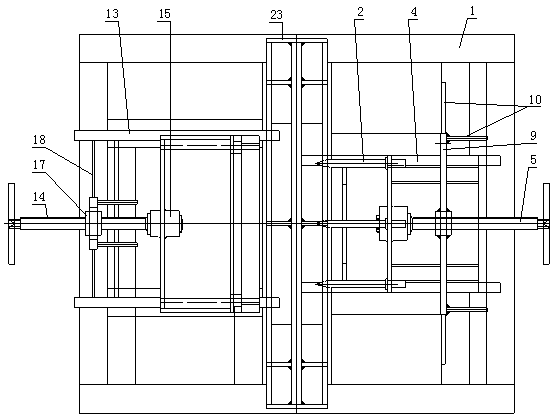

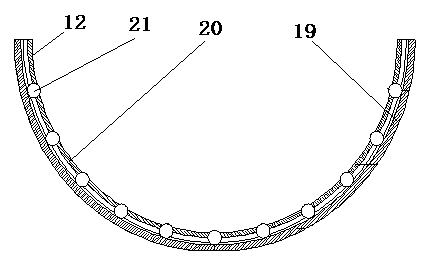

[0035] In specific implementation, such as Figure 1-Figure 3 As shown, an auxiliary device for installing a saw blade of a section steel cold saw includes a base plate 1 and a saw blade positioning seat arranged on the base plate 1. The saw blade positioning seat has a positioning groove for vertical positioning of the saw blade opening upward; The bottom plate 1 on one side of the blade positioning seat is provided with a saw blade insertion positioning mechanism, and the bottom plate on the other side is provided with a fixed disk installation mechanism;

[0036] The saw blade insertion positioning mechanism includes several positioning pins 2 installed horizontally facing the position direction of the saw blade above the positioning slot, and can drive the positioning pins along the horizontal direction to insert into the position of the saw blade above t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com