A hoisting combined power unit frame

A power unit and combined technology, which is applied in the field of hoisting combined power unit frame, can solve the problems of unfavorable fans, air ducts and optimal layout design of heat dissipation components, reduce the failure rate of auxiliary power units, and occupy convenient positions for maintenance, etc., to achieve Conducive to optimal design, facilitate structural optimization design, and improve maintainability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

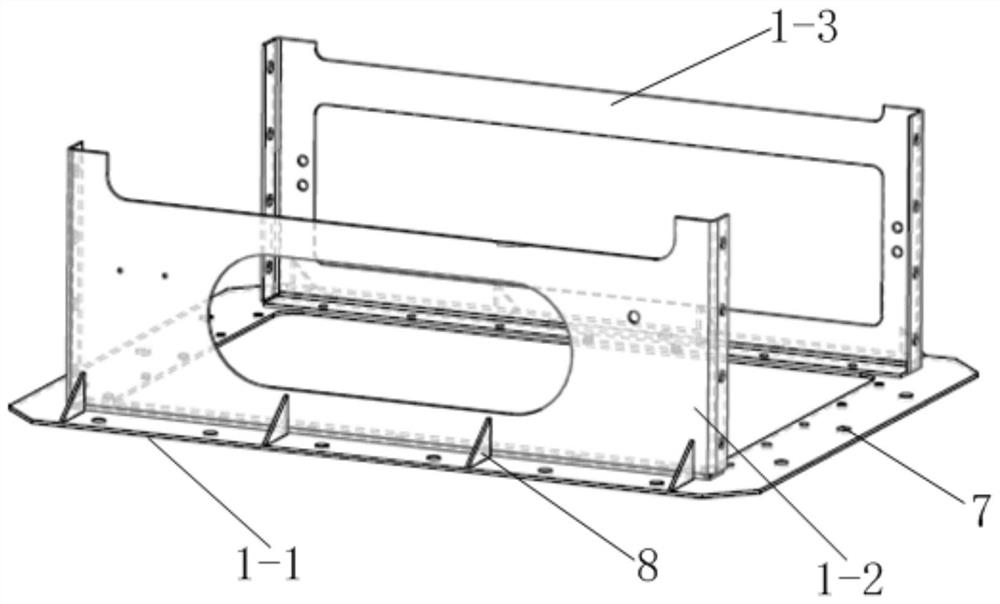

[0029] see Figure 1-3 As shown, the present invention provides a hoisting combined power unit frame, including a frame main body 1 and an assembly frame symmetrically installed on the frame main body 1,

[0030] The frame body 1 includes a frame bottom plate 1-1 at its bottom, the frame bottom plate 1-1 is provided with through holes, and the frame bottom plate 1-1 is fixedly installed on the substrate surface of the radiator 2;

[0031] Front baffle 1-2 and rear baffle 1-3 are installed on the opposite sides of the upper surface of frame bottom plate 1-1, and the left edge, right edge and bottom edge of front baffle 1-2 are all provided with holes facing through holes. Bending, the bending structure of the rear baffle 1-3 and the front baffle 1-2 is the same;

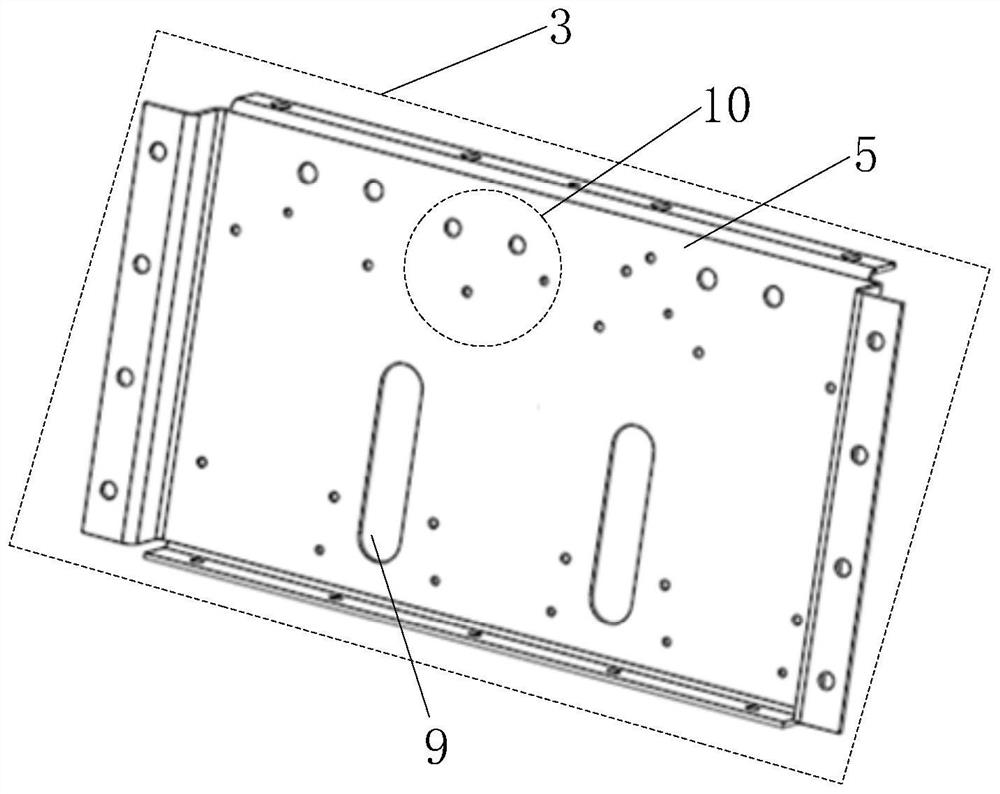

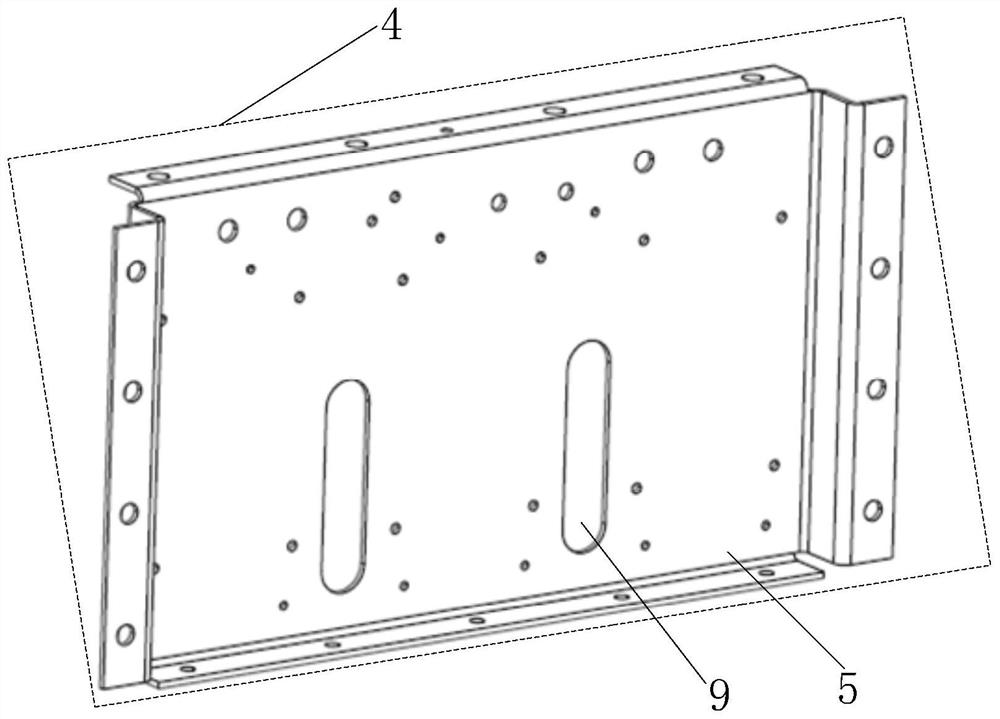

[0032] The assembly frame includes a left assembly frame 3 and a right assembly frame 4. The left assembly frame 3 includes a left assembly frame bottom plate 5 and four side bends distributed on the left assembly fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com