Amorphous alloy single-phase transformer

A technology of single-phase transformers and amorphous alloys, which is applied in the field of transformers, can solve problems such as inconvenient installation and use, and the size of single-phase transformers is not unique, and achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

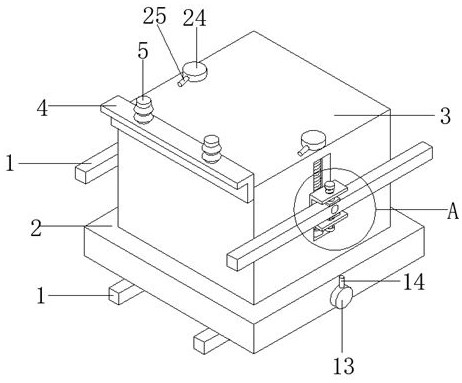

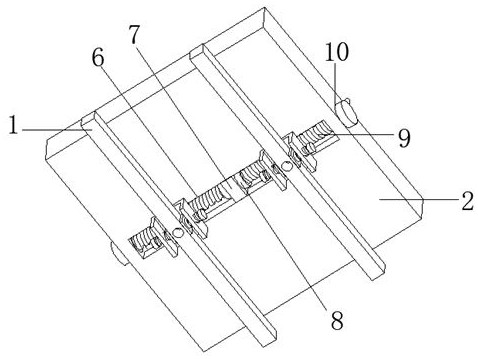

[0027] Such as figure 1 , figure 2 , image 3 and Figure 4 as shown,

[0028]An amorphous alloy single-phase transformer, including four sets of connecting skeleton plates 1 and a single-phase transformer, the single-phase transformer includes a base 2 and a transformer body 3, the top of the transformer body 3 is provided with a connecting body 4, and the upper part of the connecting body 4 is provided with a joint 5. There is a bottom chute 6 in the center of the bottom end of the base 2. The depth of the bottom chute 6 is equal to half the height of the base 2. The length of the bottom chute 6 is slightly smaller than the distance of the base 2 in this direction. The center of the bottom chute 6 is fixed. There is a fixed slider 7, the height of the fixed slider 7 is equal to the depth of the bottom chute 6, the two sides of the fixed slider 7 are fixed with bottom bearings 8, the bottom bearings 8 are rotatably connected with a bottom screw 9, and the end of the botto...

Embodiment 2

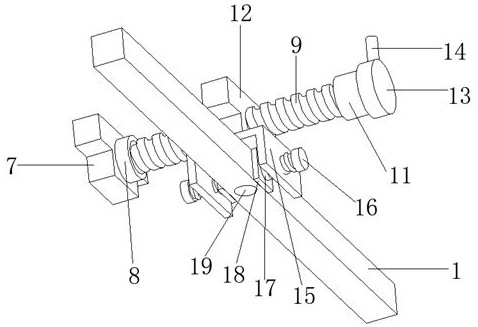

[0030] Such as image 3 , Figure 4 and Figure 5 As shown, embodiment two is a further improvement on embodiment one.

[0031] The bottom of the bottom slider 12 is fixed with a bottom concave frame 15. The height of the bottom concave frame 15 and the height of the inner cavity are equal to the height of the connecting skeleton plate 1. The threads on both sides of the bottom concave frame 15 run through a bottom adjustment screw 16, and the bottom adjustment screw 16 The length is slightly less than half of the length of the inner cavity of the bottom concave frame 15, and the end of the side wall of the bottom adjusting screw 16 is provided with a bottom matching bearing 17, and the bottom adjusting screw 16 is rotated through the bottom matching bearing 17 and is connected with a bottom limit bar 18, and the bottom limit bar The surface of 18 is a friction surface. The side of the side slider 26 is fixed with a side concave frame 27. The width of the inner cavity of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com