Electric vehicle CPU control box

A technology for electric vehicles and control boxes, applied in vehicle components, circuits or fluid pipelines, transportation and packaging, etc., can solve the problems of difficulty in ensuring dimensional accuracy, deformation of the control box, and high material costs, so as to ensure the safety of life and property, The effect of improving safety and improving self-strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

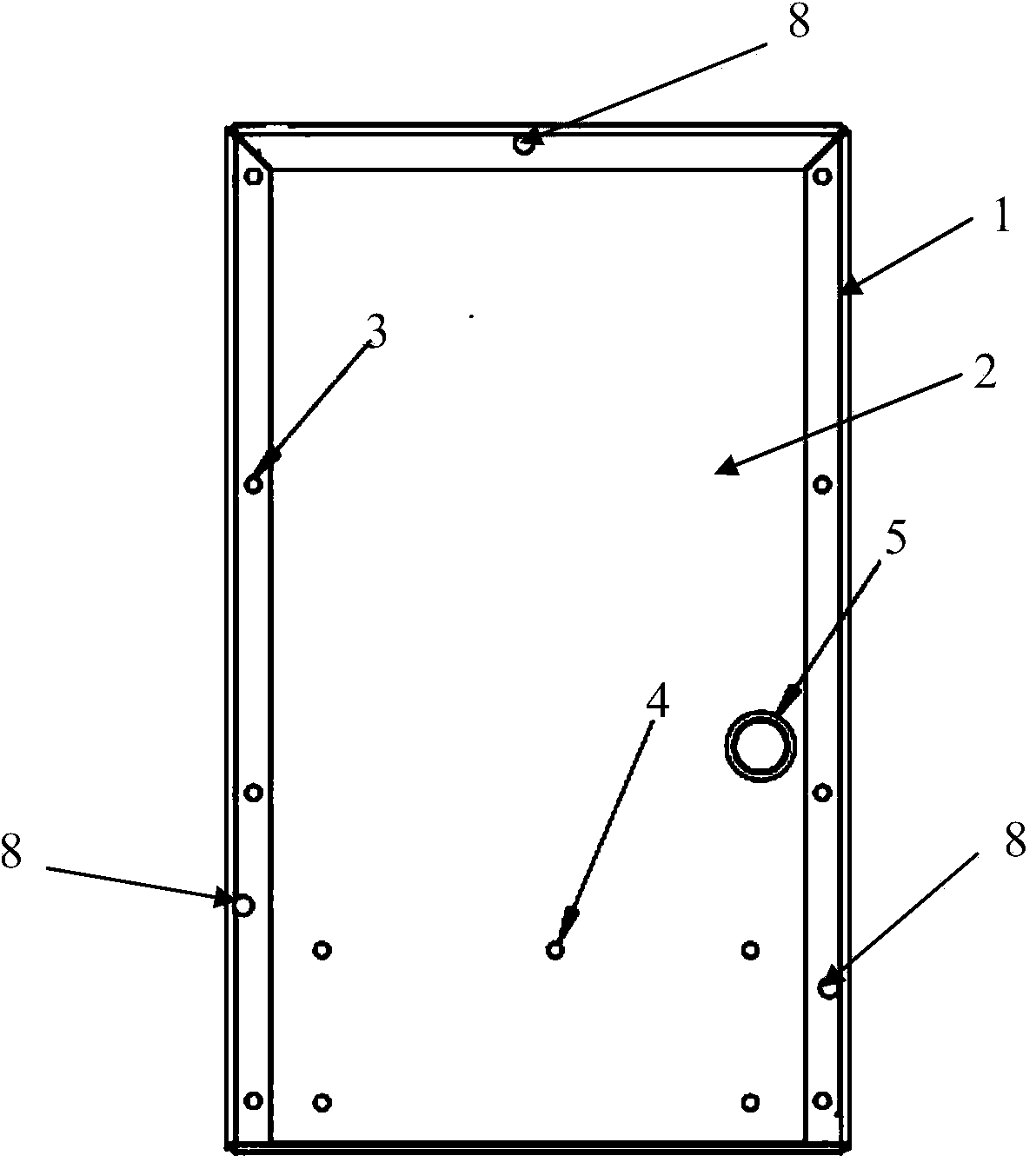

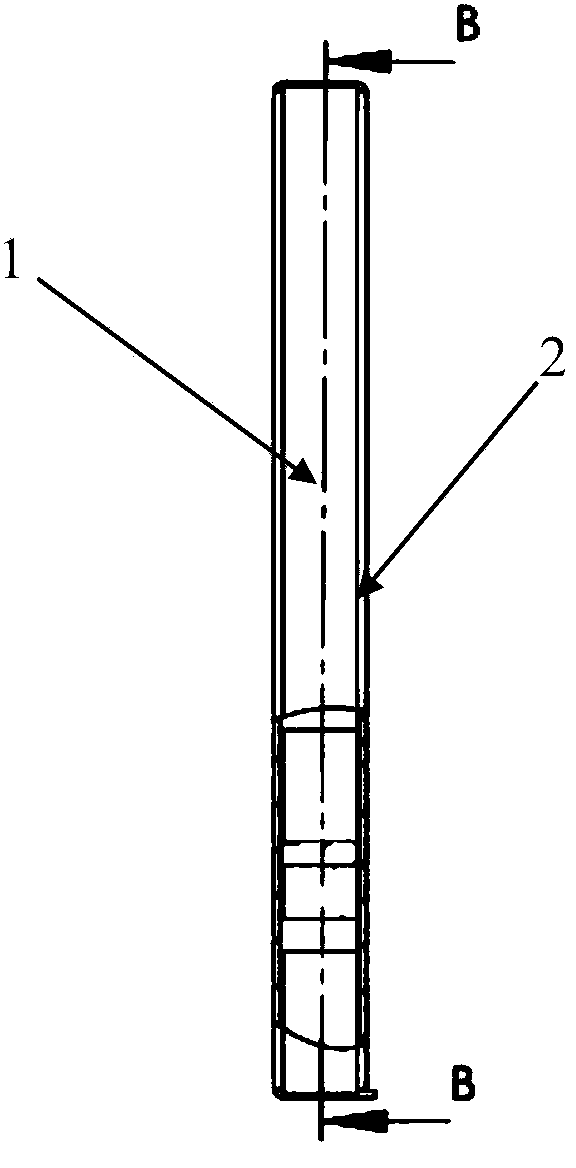

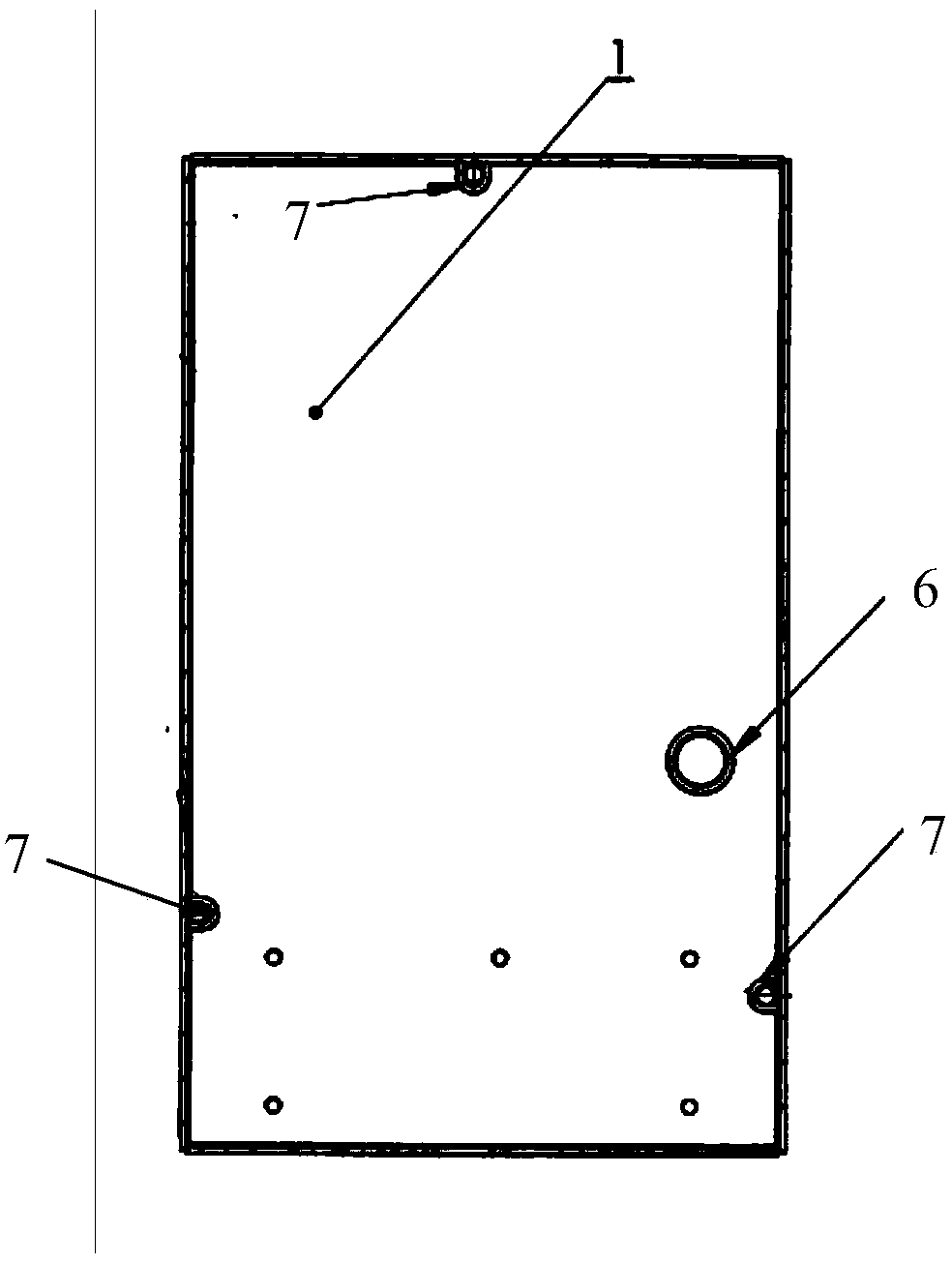

[0024] An electric vehicle CPU control box, comprising a box body 1 and a cover plate 2. The top and left and right edges of the cover plate 2 are provided with through holes 8 respectively, and the right side of the cover plate 2 is provided with through holes 5. The CPU controls There are three U-shaped protective sleeves 7 and a circular tube protective sleeve 6 inside the box. The center of the arc of the U-shaped protective sleeve 7 and the center of the corresponding through hole 8 are on the same straight line. The center of the circular tube protective sleeve 6 and the through hole The center of the circle 5 is on the same straight line to improve the heat dissipation performance of the CPU control box; the inner radius of the U-shaped protective sleeve 7 is 2.8mm, and the outer radius is 4.8mm; the inner radius of the circular tube protective sleeve 6 is 16mm, The outer radius is 20mm; there are five through holes and three spot welds on the circumference. The installa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com