Feeding device and feeding method for medical catheters

A medical catheter and feeding technology, which is applied in the directions of transportation and packaging, conveyor objects, etc., can solve the problems of easy overlapping, difficulty in taking materials, limited quantity, etc., and achieve the effect of convenient assembly and improved production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

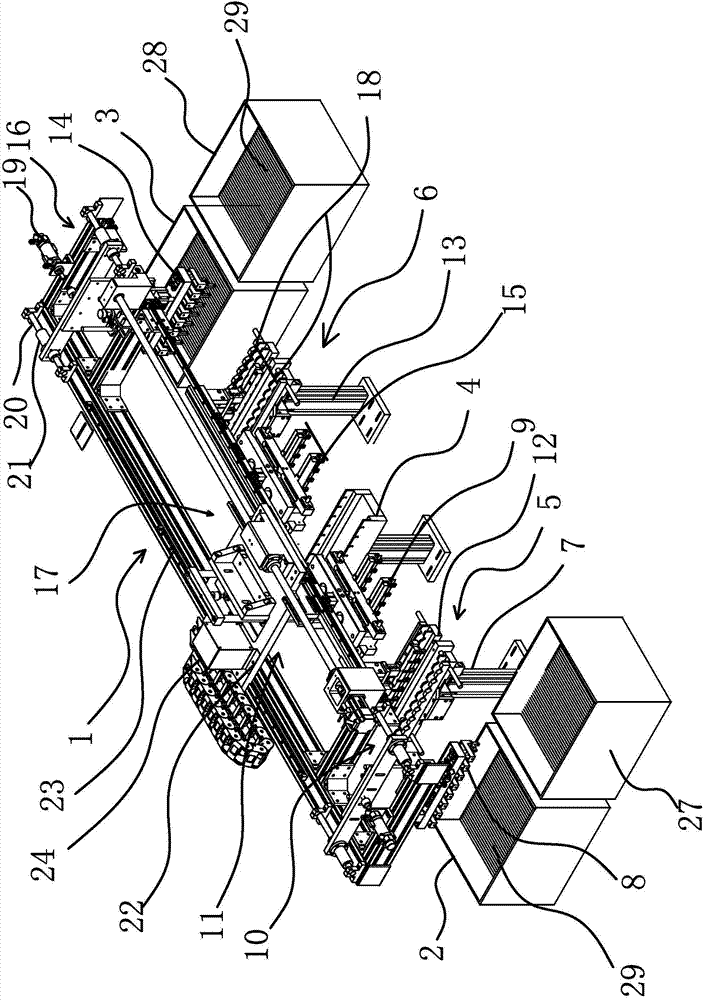

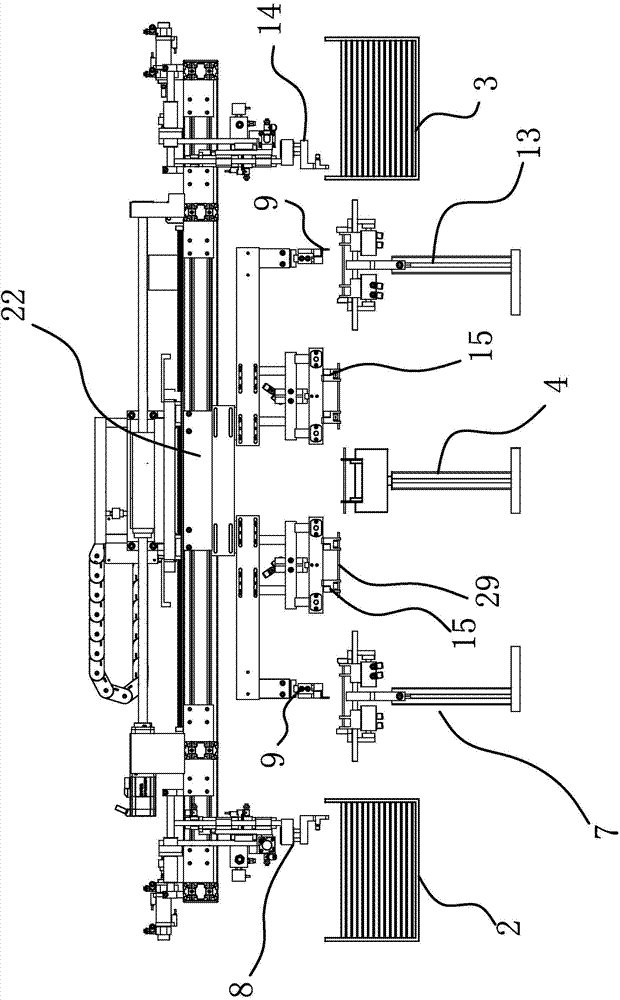

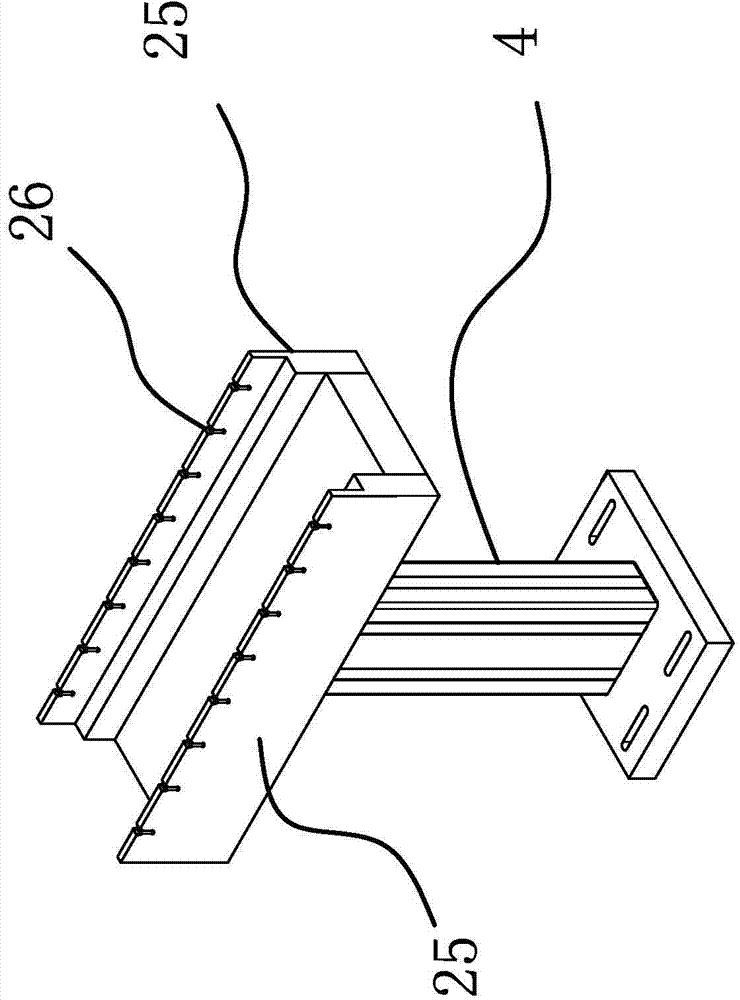

[0036] Such as figure 1 , figure 2 and image 3 As shown, the feeding device of the medical catheter 29 includes a bracket 1, the left end of the bracket 1 is provided with a material bin 2 for placing the medical catheter 29, and the right end of the bracket 1 is provided with a material bin 2 3 for placing the medical catheter 29, and the bracket 1 One side of the middle part is provided with a positioning platform 4 for positioning the medical catheter 29, and the support 1 is provided with a material transfer mechanism 5 for clamping the medical catheter 29 from the feed bin 2 and transferring it to the positioning platform 4. There is also a material transfer mechanism 2 6 for clamping the medical catheter 29 from the material bin 2 3 and transferring it to the positioning platform 4. The material transfer mechanism 1 5 and the material transfer mechanism 2 6 alternately perform the material transfer action. One side of feed bin one 2 is provided with a material prepar...

Embodiment 2

[0050] Most of the content of this embodiment is the same as that of Embodiment 1. The difference is that in this embodiment, as another solution, the material shifting mechanism 1 5 and the material shifting mechanism 2 6 are moving parts slidably connected to the bracket 1. Material manipulator one 9 and material shifting manipulator two 15, support 1 is provided with for driving material shifting manipulator one 9 to reciprocate along this support 1 left and right direction drive structure two, support 1 is provided with for driving material shifting manipulator two 15 along this The drive structure four for the reciprocating movement of the support 1 in the left and right direction. If you don't set up a monolithic platform, you can save costs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com