Reverse pushing type reactor pressure vessel and reactor internals thereof

A technology for pressure vessels and reactors, applied in the fields of reactors, nuclear reaction control, nuclear power generation, etc., can solve problems such as sticking rod accidents and inability to insert control rods, and achieve the effect of reducing the probability of leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

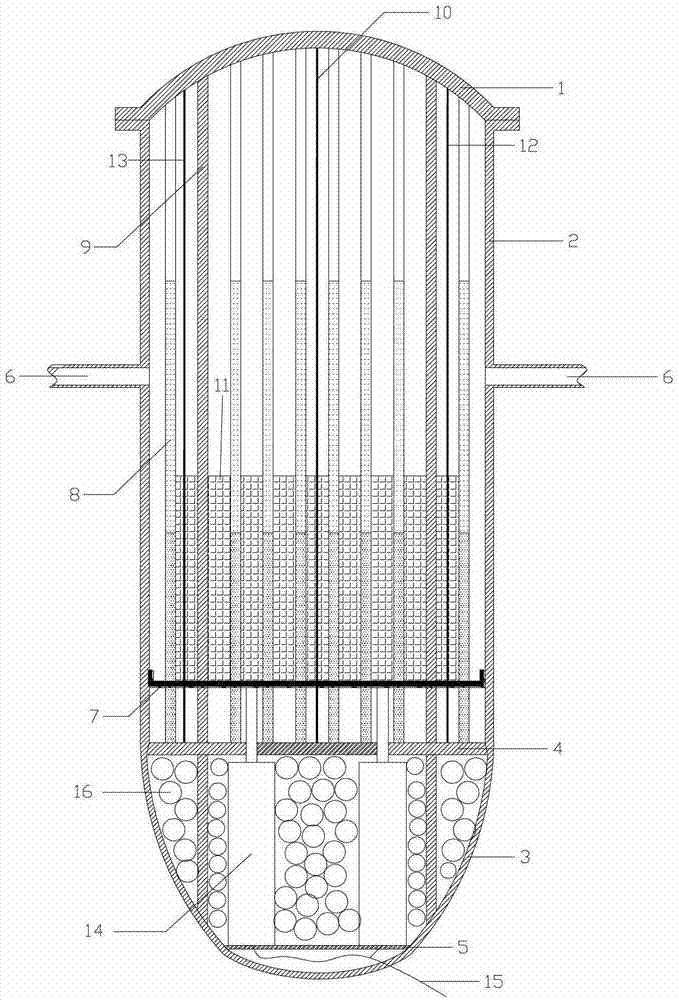

[0022] Such as figure 1 As shown, the reverse thrust reactor pressure vessel and its internal components of the present invention include a reactor pressure vessel top head 1, a reactor pressure vessel main body 2, a reactor pressure vessel bottom head 3, a main isolation plate 4, and a secondary isolation plate 5 , Input and output nozzles 6, fuel assembly trays 7, gradual change control rods 8, structural guiding steel columns in the stack 9, high-performance hydraulic jacks 14, high-performance hydraulic jack power and signal pipelines 15, neutron absorbers 16;

[0023] The reactor pressure vessel top head 1 is bolted to the reactor pressure vessel main body 2 through high-strength bolts, and the reactor pressure vessel main body 2 and the reactor pressure vessel bottom head 3 are integrally cast; the main isolation plate 4 and the seconda...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com