Constant magnetic field magnetic slider power conversion device

A technology of power transformation device and constant magnetic field, which is applied in the field of power transformation, can solve the problems of electromotive force generation, achieve the effect of no hysteresis loss and reduce eddy current loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

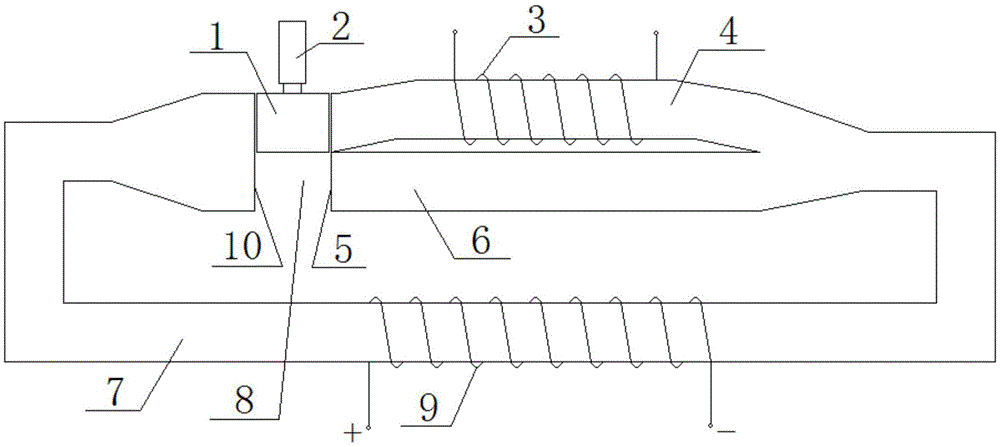

[0011] Such as figure 1 As shown, the constant magnetic field magnetic slider power conversion device includes a magnetic slider 1, a traction mechanism 2, an air gap 8, an induction coil 3, an excitation coil 9, an induction working magnetic circuit 4, a magnetic bypass 6 and a magnetic circuit 7. The magnetically conductive slider 1 is located in the air gap 8, and is driven by the traction mechanism 2 to reciprocate in the air gap 8. The induction coil 3 is wound on the induction working magnetic circuit 4; the excitation coil 9 is wound On the magnetic circuit 7 and connected with the DC power supply; the sectional area of the induction working magnetic circuit 4 is equal to the sectional area of the magnetic circuit 7, and the sectional area of the magnetic conduction bypass 6 is also equal to the sectional area of the magnetic circuit 7, and the conduction One end of the magnetic bypass 6 is parallel to one end of the induction working magnetic circuit 4 to form ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com