Magnetic particle field flow separation device and method based on rotating magnetic field

A magnetic particle and field flow separation technology, applied in magnetic separation, chemical instruments and methods, solid separation, etc., can solve problems such as low precision and difficult implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

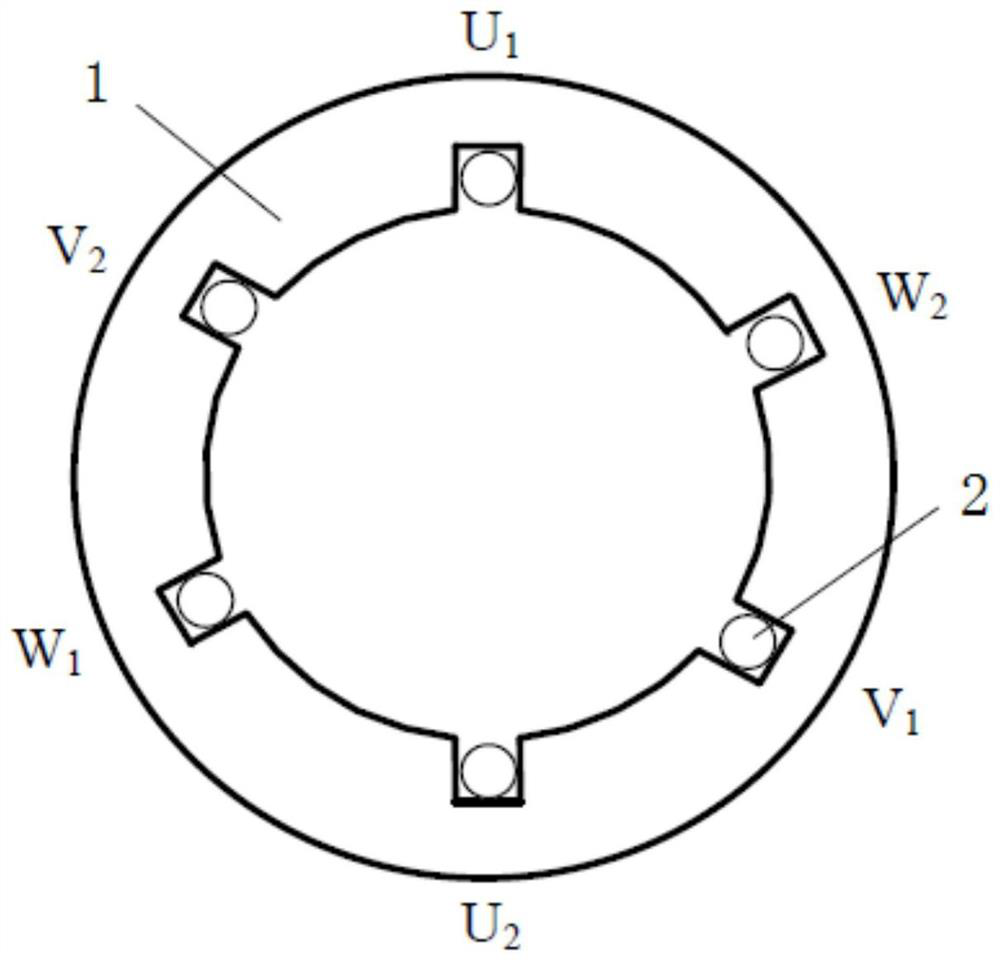

[0047] like Figure 1-Figure 6 As shown, a magnetic particle field flow separation device based on a rotating magnetic field, including a three-phase winding 2;

[0048] The three-phase winding 2 includes a first phase winding, a second phase winding and a third phase winding;

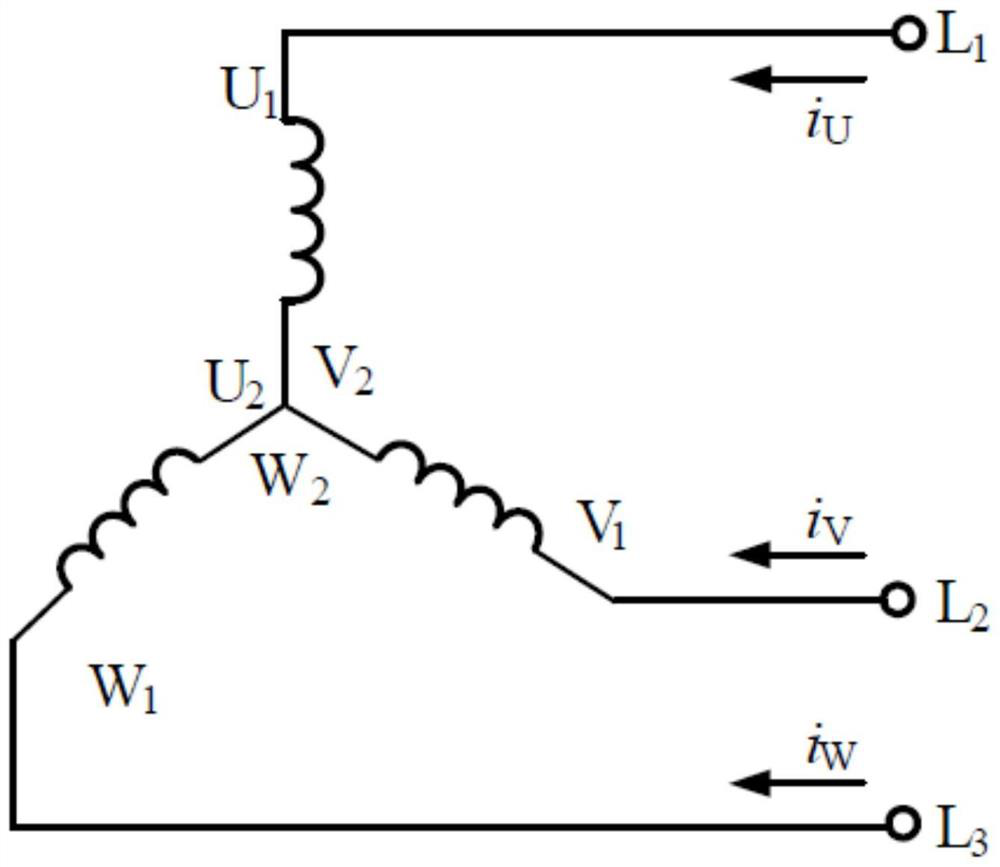

[0049] The first phase winding, the second phase winding and the third phase winding are star-connected and arranged on the base 1 axisymmetrically with the axis of the base 1;

[0050] The base 1 is a cast iron base;

[0051] The head end U of the first phase winding, the second phase winding and the third phase winding 1 , V 1 , W 1 Respectively with the output terminal L of the three-phase power supply 1 , L 2 , L 3 connected, the output current of the three-phase power supply is a symmetrical three-phase sinusoidal alternating current;

[0052] The base 1 is a hollow structure, and a separation channel is provided in the space surrounded by it;

[0053] The input end of the separation chan...

Embodiment 2

[0067] A method for magnetic particle field flow separation based on the magnetic particle field flow separation device described in embodiment 1, has the following steps:

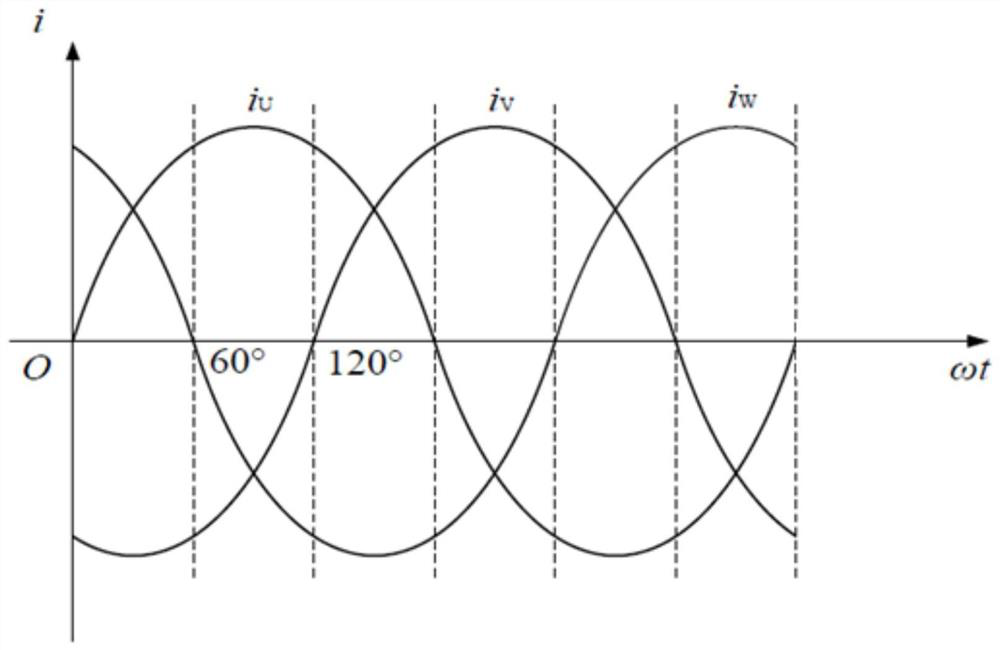

[0068] S1. The three-phase power supply inputs current i to the first phase winding, the second phase winding and the third phase winding respectively U i V i W , forming a rotating magnetic field in the space surrounded by the base 1, and adjusting the frequency of the rotating magnetic field and the voltage on the three-phase winding through the frequency converter 5;

[0069] S2. When the thickness of the plastic cylinder is constant, by changing the diameter of the inner wall and the diameter of the outer wall of the plastic cylinder, the radial position of the microtube is adjusted, and the magnetic induction intensity at the position of the separation channel is changed;

[0070] S3, the magnetic particles with different magnetic susceptibilities injected through the injection syringe 8 and the mob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com