Heater and fixing device and drying device equipped with the same

A heater and resistor technology, applied in the field of fixing devices, drying devices, and heaters, can solve problems such as low temperature of heating elements, damage to peripheral parts, and difficulty in temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0239] (1) Manufacture of stainless steel heater

[0240] I made it with the following points Figure 40 The stainless steel heater 1A is shown.

[0241] After smoothing the surface of the substrate (length 270mm, width 24mm and thickness 0.6mm) made of SUS430, the composition was SiO 2 -Al 2 o 3 - The crystallized glass forming material of RO was coated on the entire surface of the substrate so that the thickness after the drying treatment was 100 μm. Next, the coating film was fired at 850° C. to obtain an insulating layer made of crystallized glass with a film thickness of 85 μm.

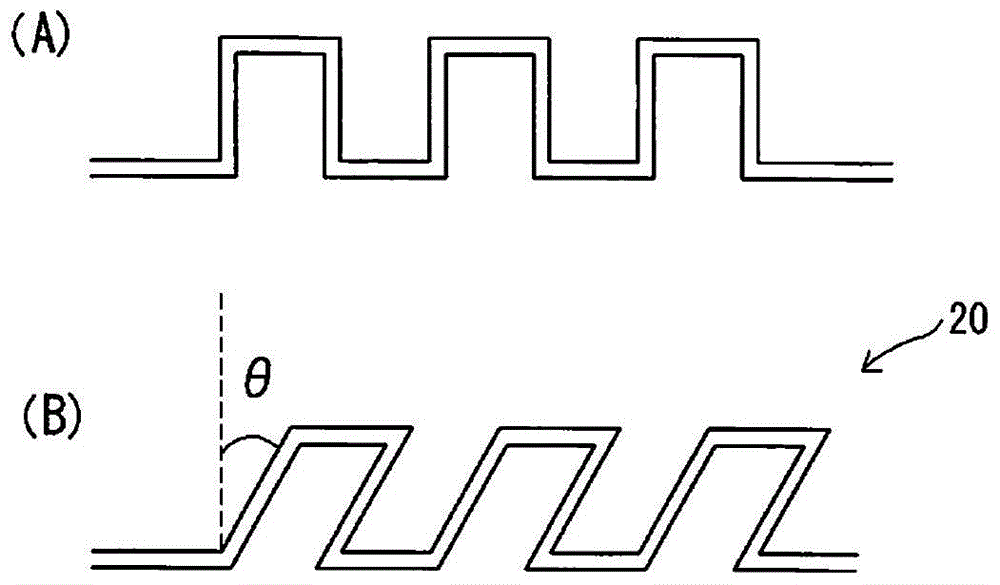

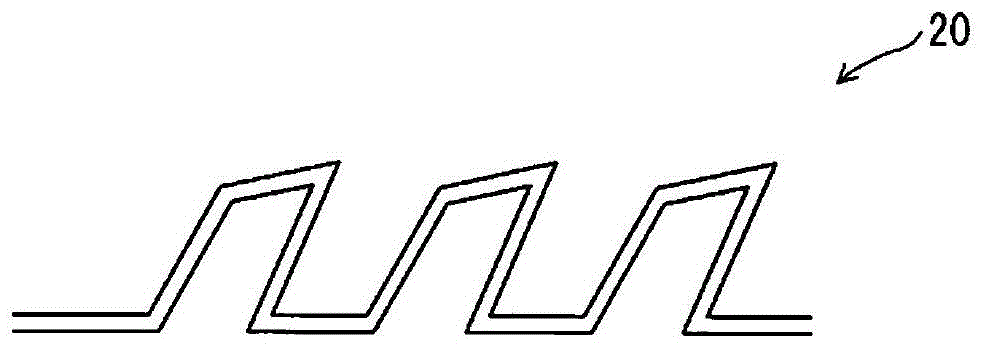

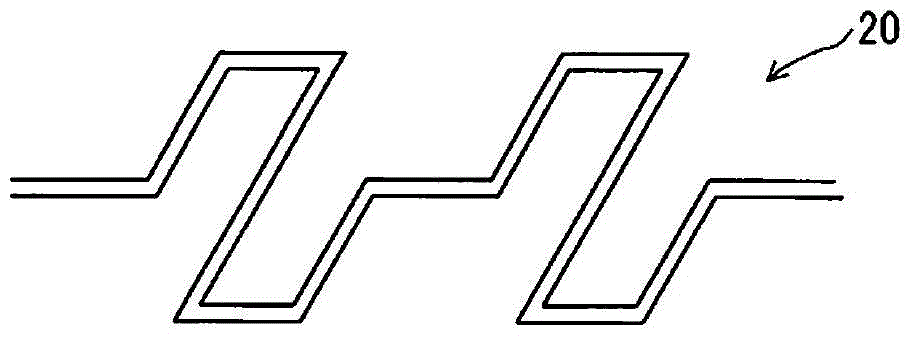

[0242] Afterwards, using a paste that does not contain lead, cadmium, and nickel but contains powder composed of silver-palladium alloy (the temperature coefficient of resistance is 1500ppm / °C), the surface of the insulating layer 13 is printed with materials including Figure 40 Including the inclined rectangular pattern of the shown resistance heating wiring portion 15 , a loop-shaped patt...

Embodiment 2

[0251] As the paste for constituting the resistance heating wiring portion 15, a paste containing powder composed of silver-palladium alloy (temperature coefficient of resistance: 1000ppm / °C) is used to form a paste having Figure 44 The resistance heating wiring part 15 of the shown pattern was manufactured in the same manner as in Example 1 except for this. Figure 44 The shown stainless steel heater 1A was evaluated in the same manner as in Example 1.

[0252] Express the experimental results for evaluating E1 in Figure 45 middle. according to Figure 45 , when the radiator 3A is in contact with the position (P) and the position (R) in the stainless steel heater 1A, the temperature at each position is reduced by about 30°C to 40°C, and when the radiator 3A is in contact with the position (Q) , the temperature at the position (P) and the position (R) increased by about 60°C to 70°C.

Embodiment 3

[0260] (1) Manufacture of stainless steel heater

[0261] We made with the following points Figure 51 The stainless steel heater 1B is shown.

[0262] After smoothing the surface of the substrate (length 270mm, width 24mm and thickness 0.6mm) made of SUS430, the composition was SiO 2 -Al 2 o 3 - The crystallized glass forming material of RO was coated on the entire surface of the substrate so that the thickness after the drying treatment was 39 μm. Next, the coating film was fired at 850° C. to form a crystallized glass thin film with a film thickness of 25 μm. The coating and firing treatments were repeated twice each to obtain an insulating layer with a film thickness of 75 μm.

[0263] Afterwards, using a paste containing powder composed of silver-palladium alloy (the temperature coefficient of resistance is 1500ppm / ℃), printed on the surface of the insulating layer, including Figure 51 Including the inclined rectangular pattern of the shown resistance heating wirin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com