Fertilization position and transport position changeover mechanism for paddy field fertilization device

A technology of a fertilization device and a conversion mechanism, which is applied in the directions of fertilization devices, fertilizer distributors, applications, etc., can solve the problems of inability to achieve independent adjustment, poor adaptability, and independent control, and achieve simple and convenient conversion and adjustment, improve adaptability, and use reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

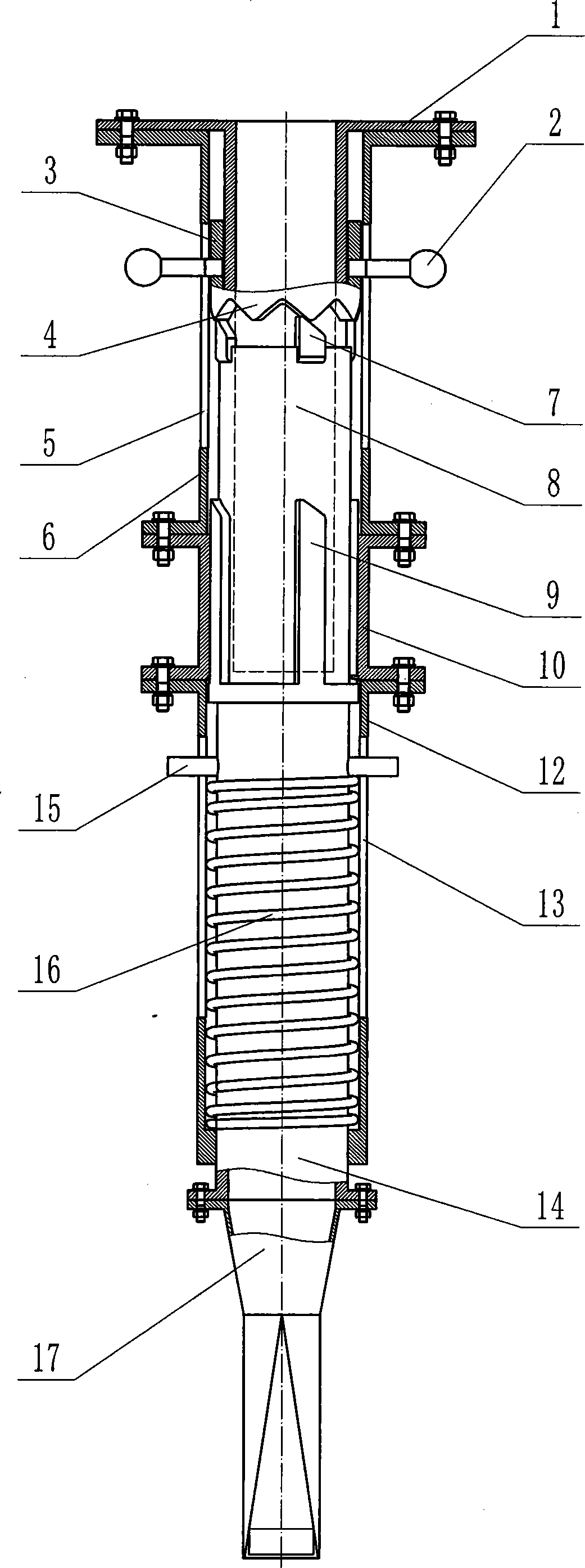

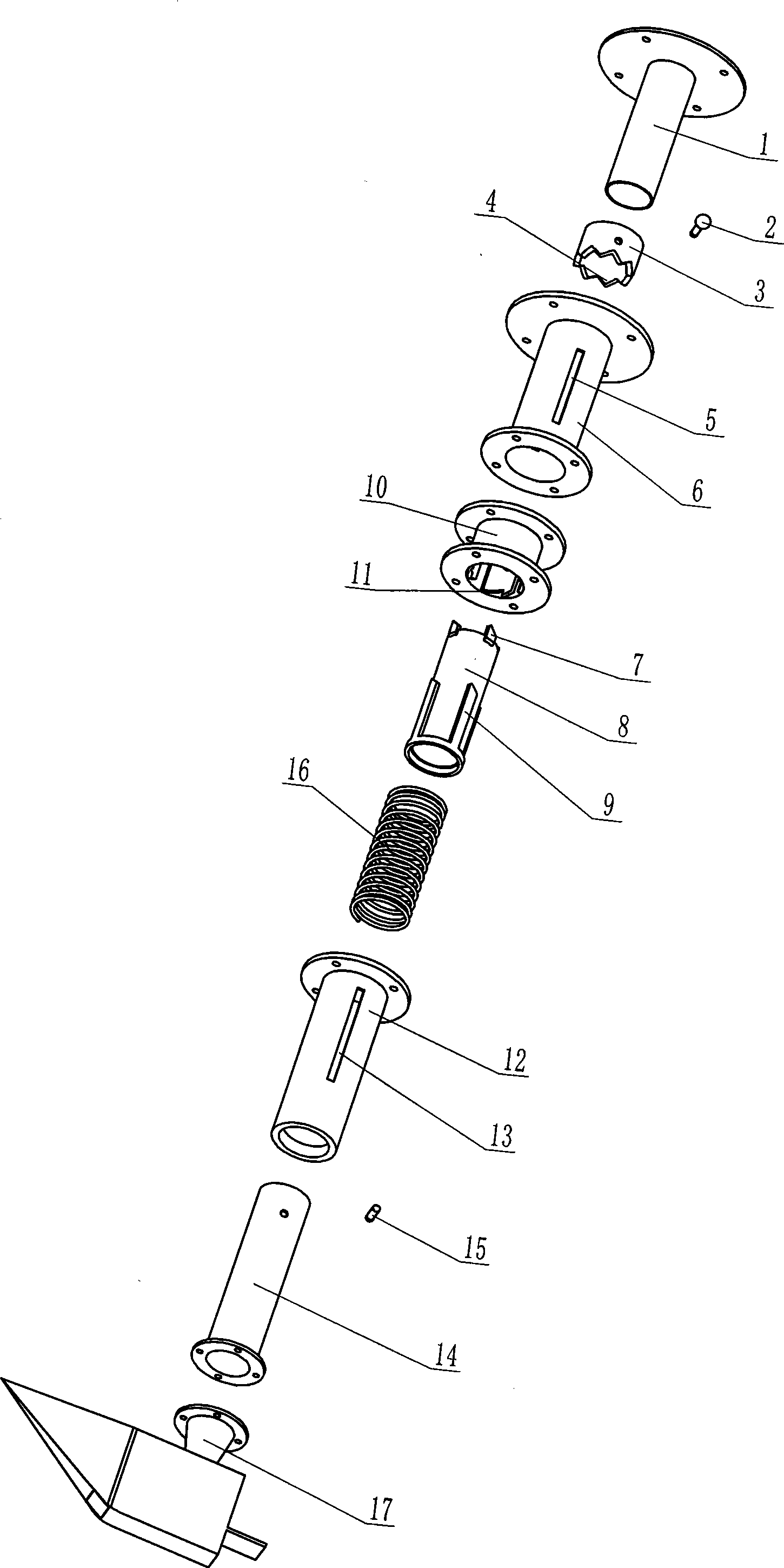

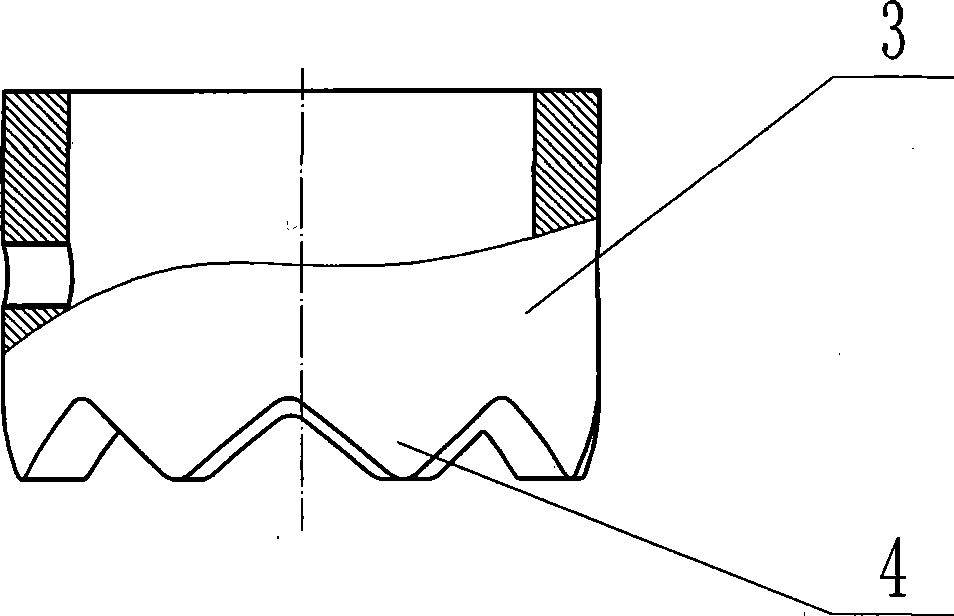

[0013] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A fertilization position and transport position conversion mechanism for a paddy field fertilization device, the upper sleeve 6 and the lower sleeve 12 are respectively fixed on the upper and lower parts of the guide sleeve 10, and the inner wall surface of the guide sleeve 10 is set in the axial direction. The bit boss 11, on the wall of the upper sleeve 6, an upper chute 5 is axially symmetrically provided, and on the wall of the lower sleeve 12, a sliding groove 13 is provided axially symmetrically, and the expansion and contraction of the sleeve pressure spring 16 The tube 14 is mated and installed in the lower sleeve 12, and the positioning pin 15 is axially movable and inserted in the sliding groove 13. The inner end of the positioning pin 15 is connected with the telescopic tube 14, and the upper end of the pressure spring 16 Contact and cooperate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com