Electric heating pressure stewing utensil

A cooking utensil and pressure technology, which is applied in the direction of pressure cooker, steam cooking utensils, cooking utensils, etc., can solve the problems of increasing production costs, and achieve the effects of saving energy, improving food cooking quality, and reducing ambient temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

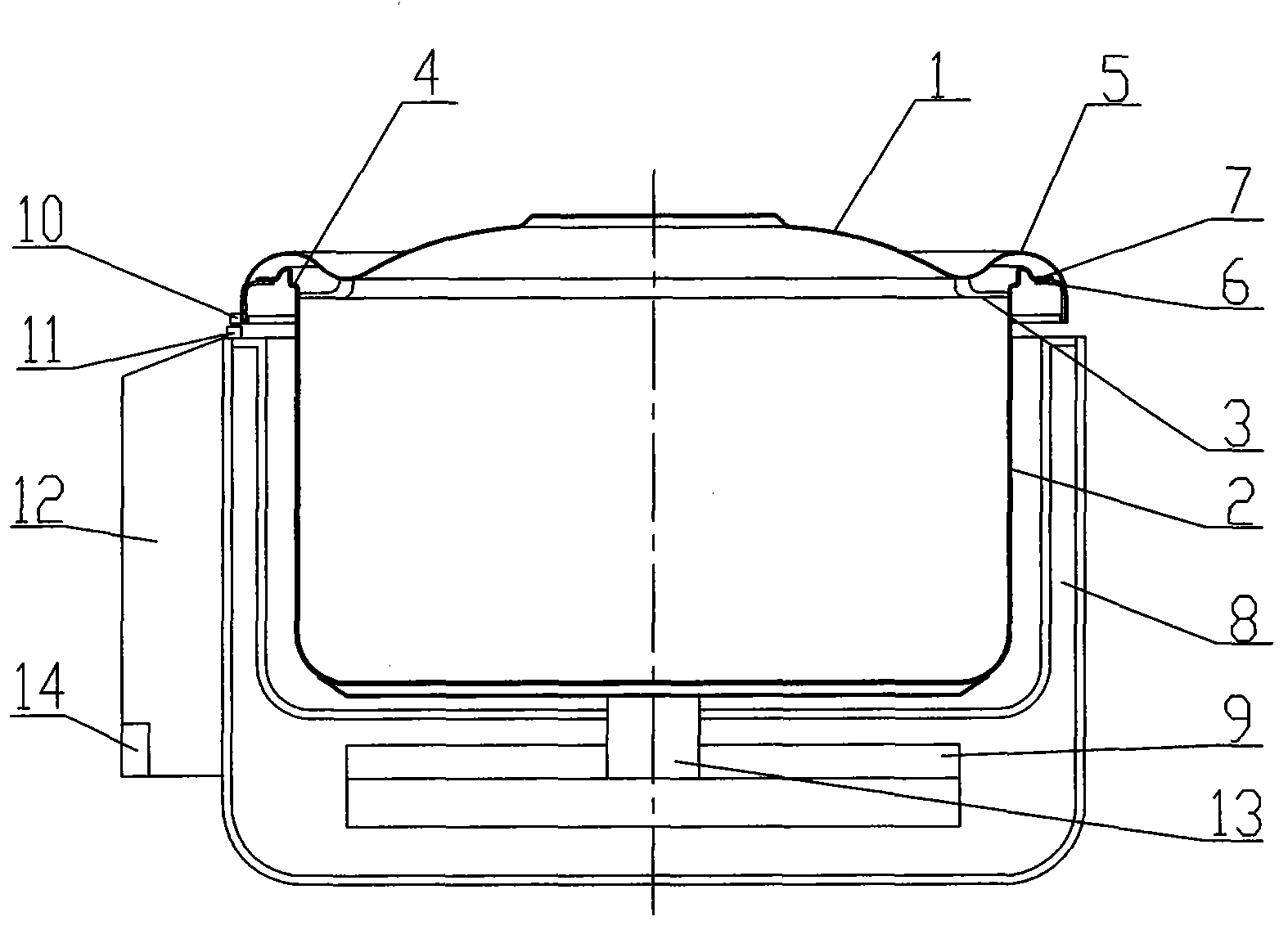

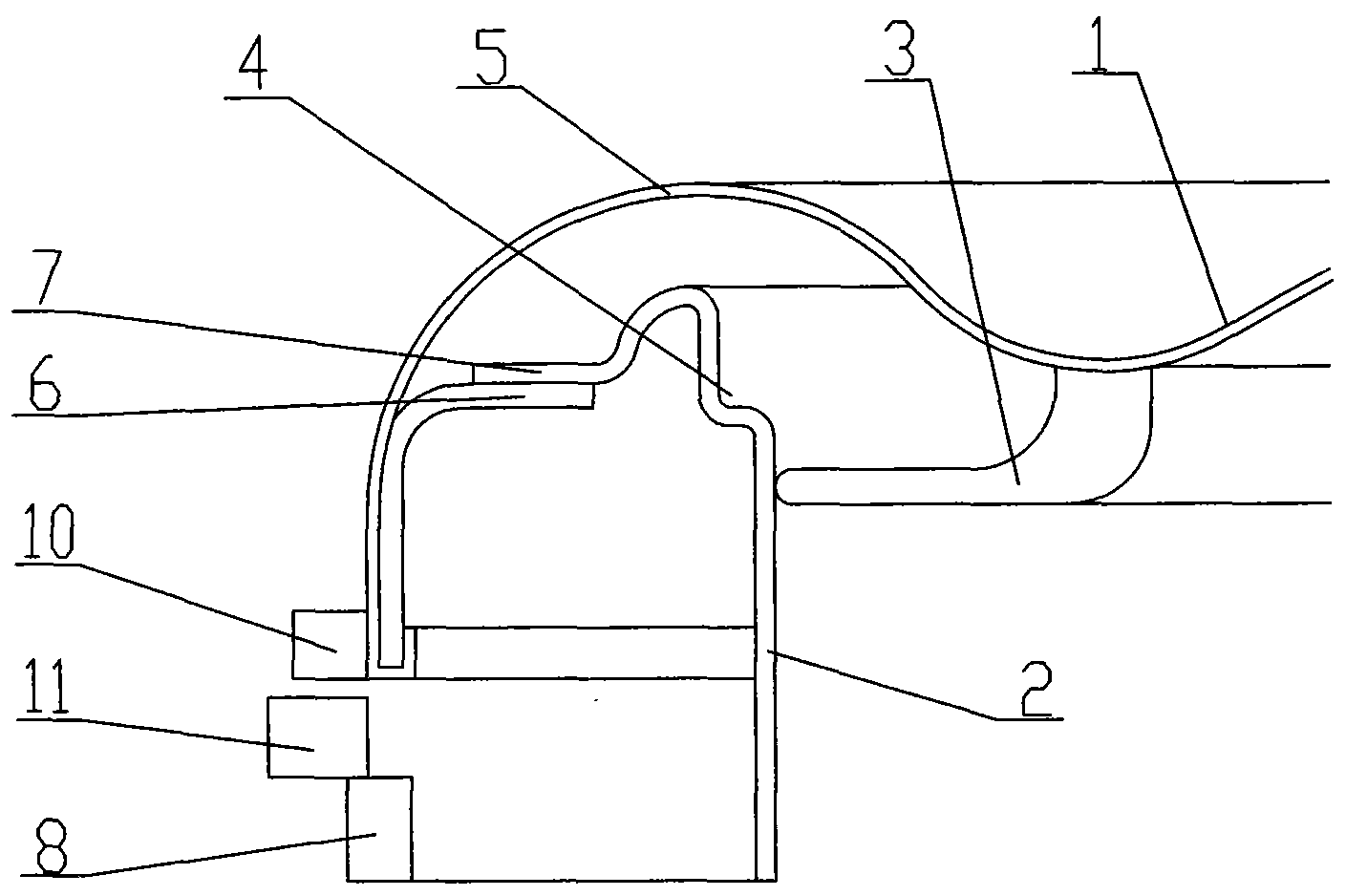

[0025] Embodiment 1: see figure 1 , figure 2 , Figure 5 , Figure 6 . The pot cover 1, the pot body 2 and the elastic structural member 5 are all made of stainless steel plates. The connection structure of this embodiment adopts a right-handed screw structure: the elastic structural member 5 is made into a corrugated shape, and one end thereof is fixedly arranged on the outer edge of the pot cover 1 or integrated with the pot cover 1 . At the other end of the elastic structural member 5, 6 cap teeth 6 with a small rise angle (such as 2°) are evenly arranged along the circumference. Combined with the elastic displacement parameters of the elastic structural member 5, the vertical elevation difference between the head end and the end of the cap tooth 6 is selected within the range of several millimeters. Six pot teeth 7 matched with the lid teeth 6 are set along the circumference on the upper mouth of the pot body 2 .

[0026] The sealing ring 3 is made of silicon rubber...

Embodiment 2

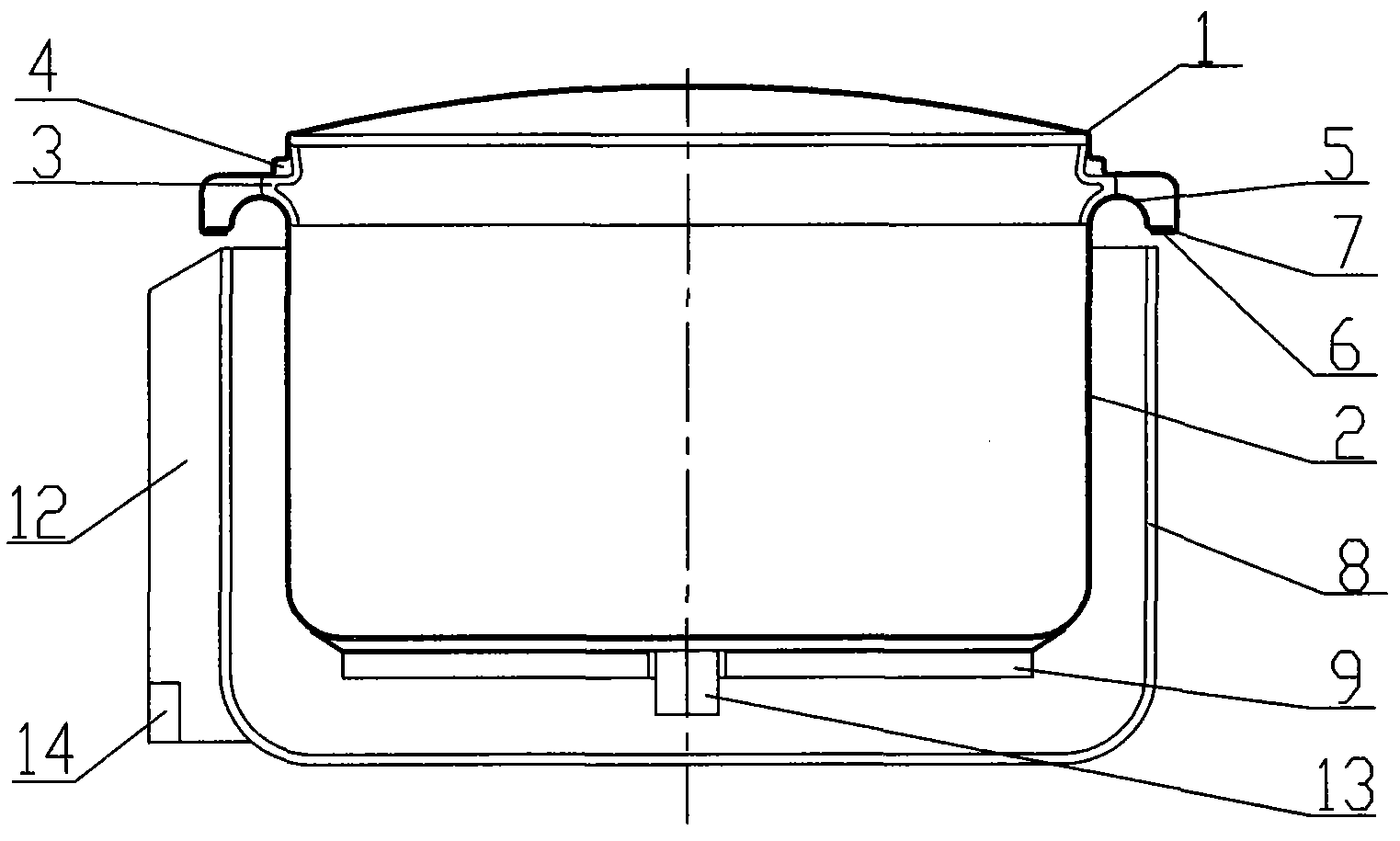

[0031] Example 2: see image 3 , Figure 4 . The pot cover 1, the pot body 2 and the elastic structural member 5 are all made of high-quality stainless steel plates. The connecting structure of this embodiment adopts the right-handed flat tooth structure. The elastic structural member 5 is arranged on the mouth of the pot body 2: one end of the elastic structural member 5 is fixed on the mouth of the pot body 2 or is integrated with the pot body 2, and the other end is provided with six pot teeth 7 along the circumference. The outer edge of the pot cover 1 is provided with 6 cover teeth 6 matched with the above-mentioned pot teeth 7 .

[0032] The sealing ring 3 is made of silicon rubber, and one end of the sealing ring 3 is fixed on the mouth of the pot body 2 by a fixed structure, so that the other end and the pot cover 1 form a dynamic seal. Six pressure relief grooves 4 are arranged on the sealing part of the pot cover 1 along the circumference. The pressure relief gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com