A 6-ptrt parallel robot with self-calibration function

A 6-PTRT and robot technology, applied in manipulators, manufacturing tools, program-controlled manipulators, etc., can solve the problems of fewer parallel mechanisms, complex mechanisms, and poor processing, and achieve large working space, high motion safety, and reduced quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manners of the present invention are given below and described in conjunction with the accompanying drawings.

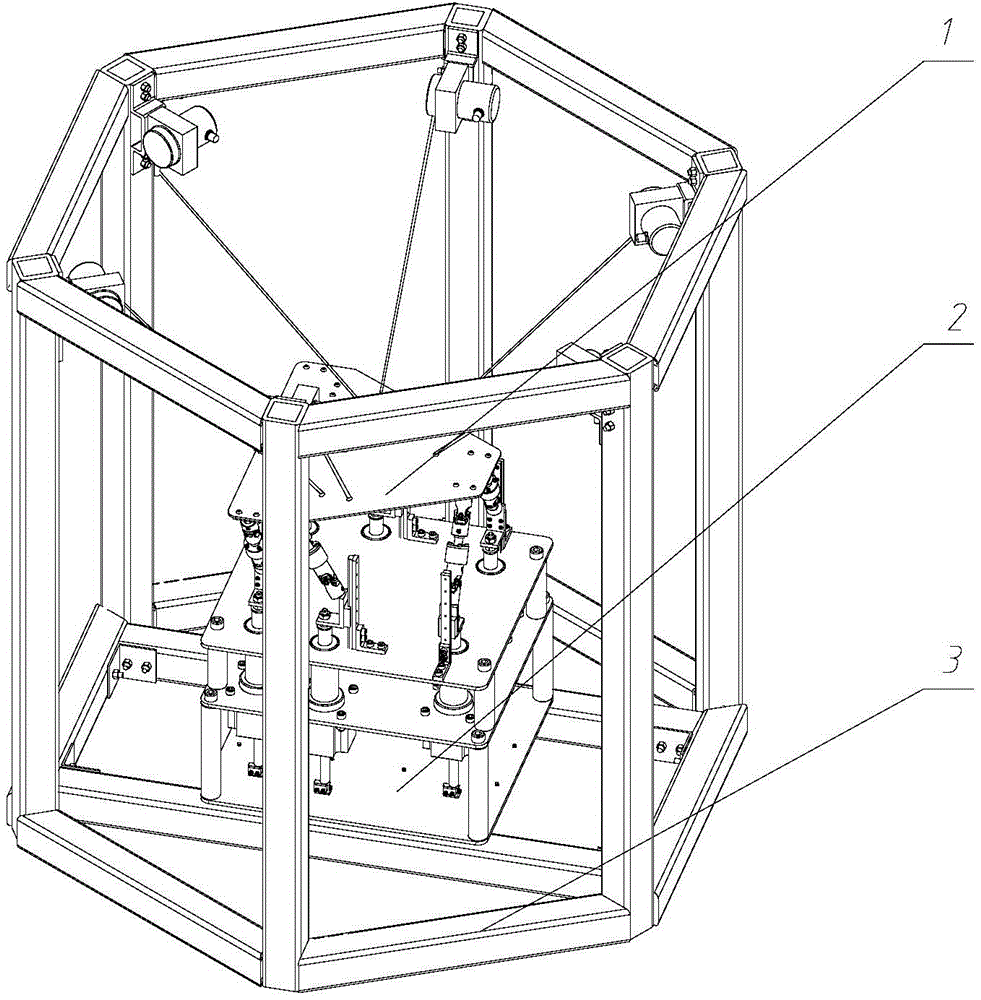

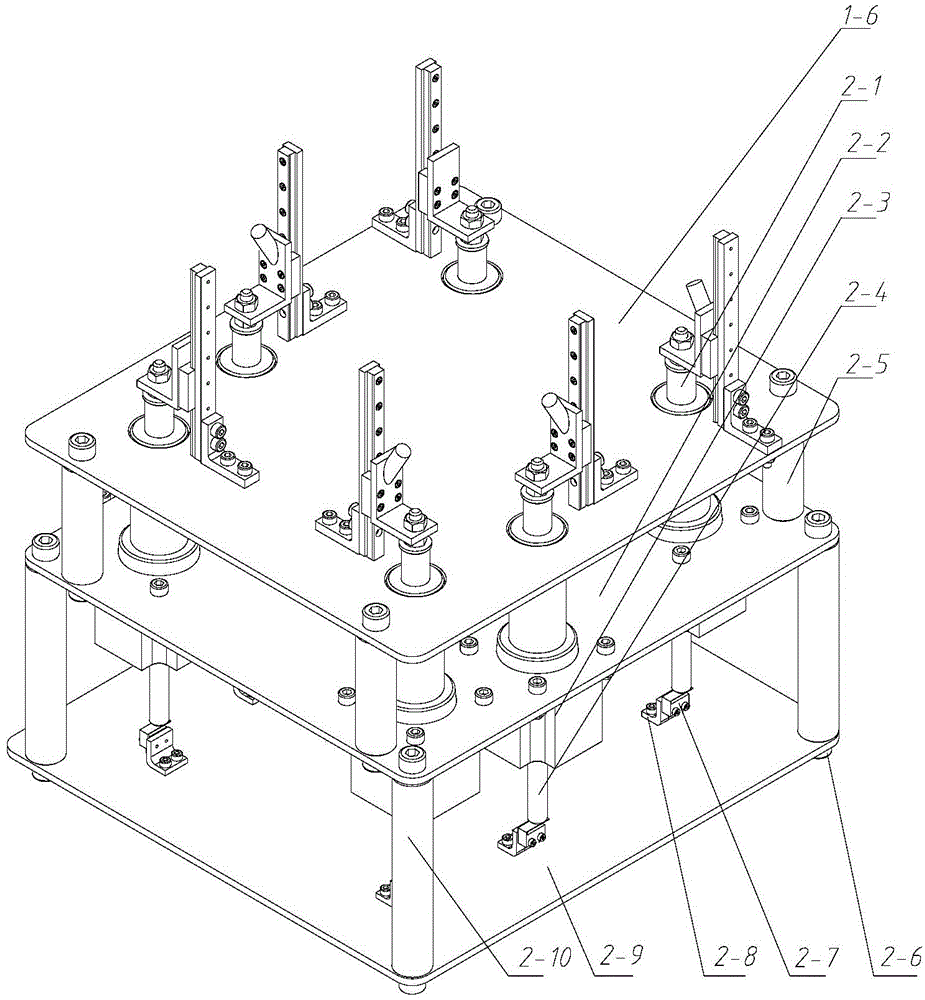

[0017] to combine figure 1 , a 6-PTRT type parallel robot mechanism of the present invention is mainly composed of a six-degree-of-freedom motion platform 1, a driving device 2, and a detection device 3. The six-degree-of-freedom motion platform 1 can completely position objects in space, and also The spatial attitude of the object can be simulated; the driving device 2 is composed of six linear stepper motors and zero position detection, and is mainly used to drive the movement of the six-degree-of-freedom platform; the calibration device 3 detects the pull wires on the six corners of the regular hexagonal truss The sensor obtains the actual position and attitude of the moving platform through kinematics.

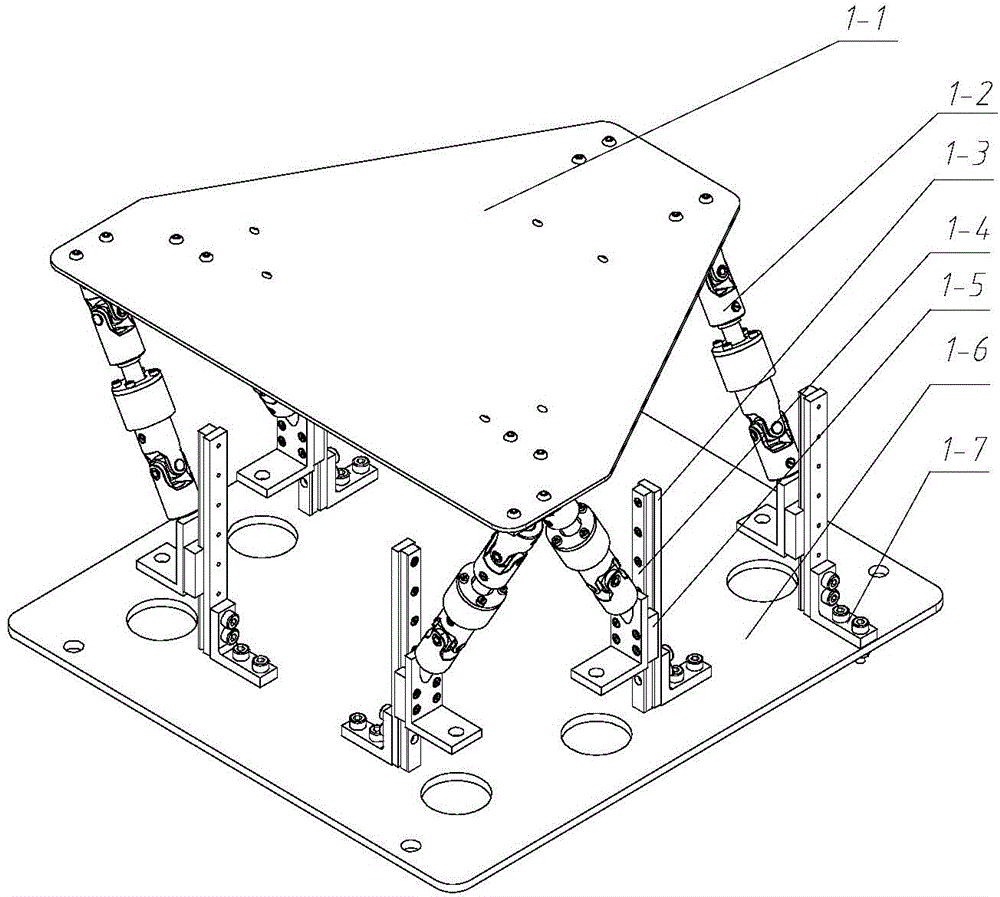

[0018] to combine figure 2 The six-degree-of-freedom motion platform 1 mainly includes a dynamic platform 1-1, a linkage me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com