External convex curtain wall glass mounting bracket

A technology for installing brackets and glass, applied to walls, building components, buildings, etc., can solve problems such as safety hazards, structural instability, slow installation speed, etc., and achieve the effects of preventing glass from shattering, stable structure, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

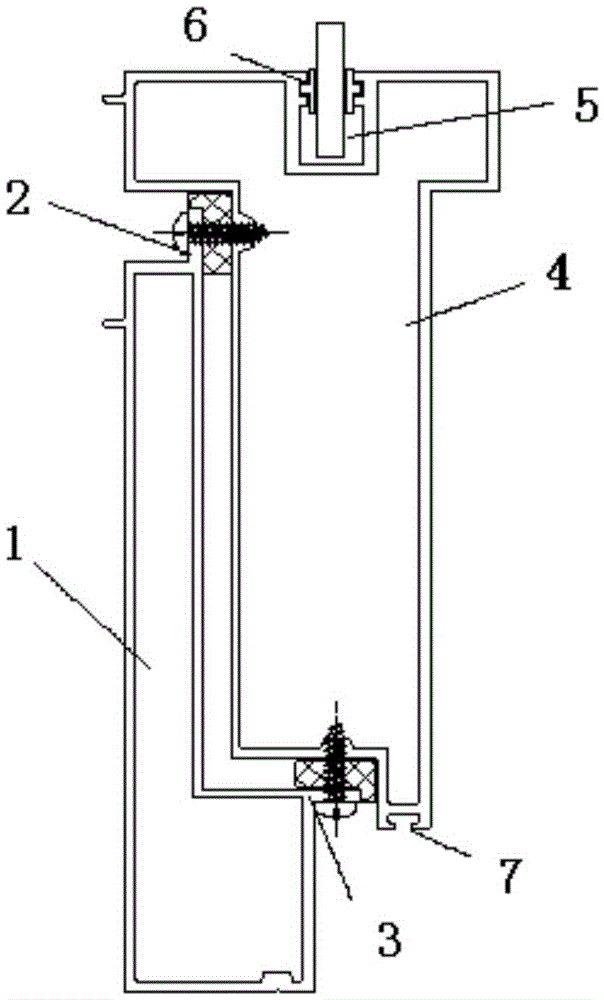

[0015] Referring to the accompanying drawings, an external convex type curtain wall glass installation bracket includes a base 1, the base 1 is an L-shaped structure, and fixed mounting plates 2 and 3 are provided on the upper and lower side walls of the base 1 , a glass mounting seat 4 is fixedly installed on the upper and lower two fixed mounting plates 2 and 3 by fastening bolts, the upper end of the glass mounting seat 4 is provided with a glass mounting groove 5, and the inner wall of the glass mounting groove 5 is A shock pad 6 is provided.

[0016] The structure of the glass mounting seat 4 is a T-shaped structure, and the bottom is provided with a sealing strip groove 7 .

[0017] The base 1 is composed by weight percentage: Si≤0.4, Fe≤0.3, Cu3.6-4.2, Mg1.5-2.3, Mn0.5-1.0, Zn≤0.25, Ti≤0.15, Ni0.4-0.6, V0 .2-0.3, Be0.15-0.25, Hf0.1-0.2, Rh0.05-0.1, Sc0.04-0.08, Y0.03-0.06, Lu0.02-0.04, and the balance is Al.

[0018] The preparation method includes the following steps...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com