A preparation method for a TSV sample

A sample and sample processing technology, applied in the preparation of test samples, etc., can solve time-consuming problems, achieve the effects of improving preparation efficiency, shortening preparation time, and improving shape flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The preparation method of the TSV sample proposed by the present invention will be further described in detail below with reference to the accompanying drawings and specific examples.

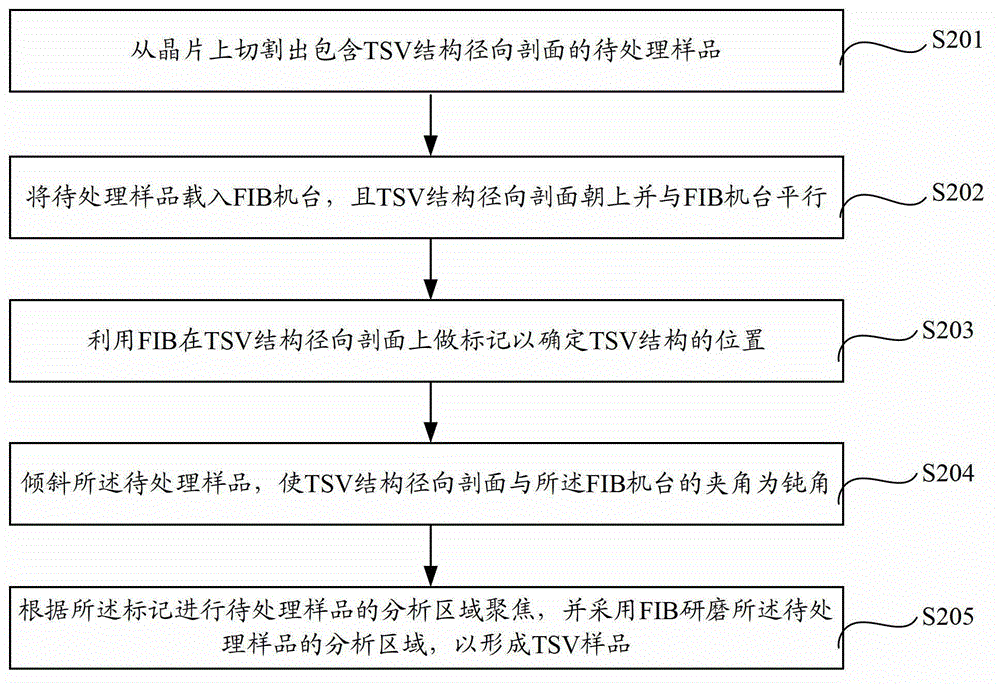

[0033] Please refer to figure 2 , the invention provides a kind of preparation method of TSV sample, comprises the following steps:

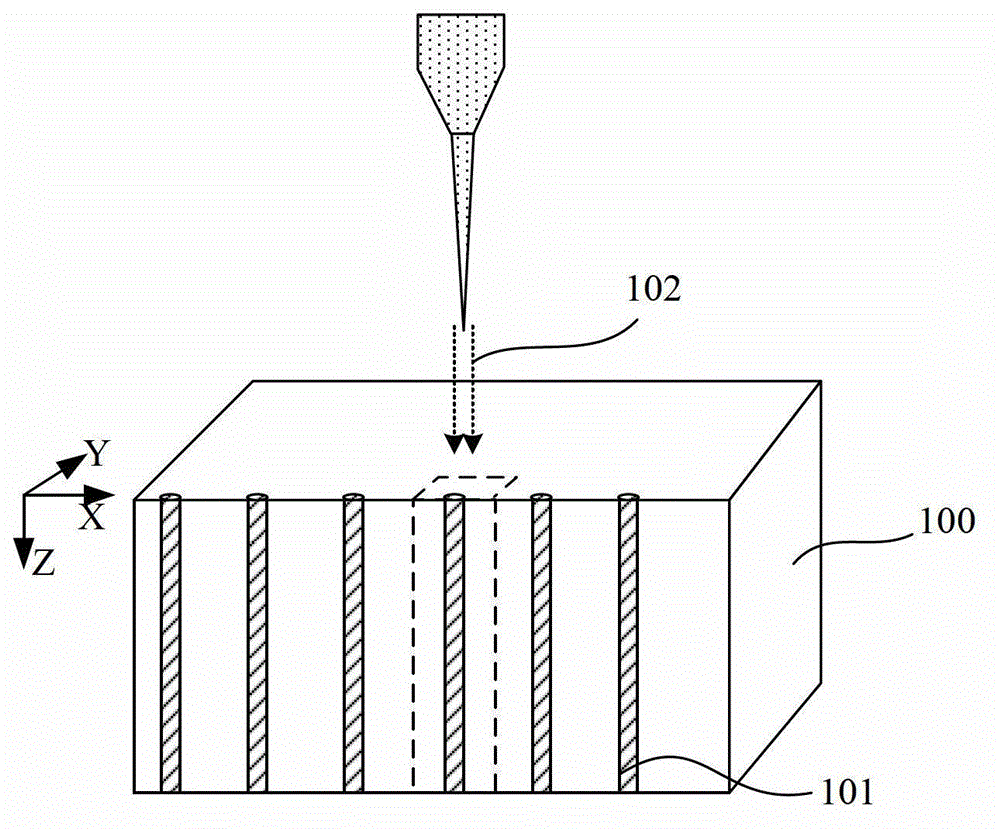

[0034] S201, cutting out a sample to be processed including a radial section of the TSV structure from the wafer;

[0035] S202, load the sample to be processed into the FIB machine, and the radial section of the TSV structure faces upward and is parallel to the FIB machine;

[0036] S203, using the FIB to mark the radial section of the TSV structure to determine the position of the TSV structure;

[0037] S204, tilting the sample to be processed so that the angle between the radial section of the TSV structure and the FIB machine is an obtuse angle;

[0038] S205. Perform focusing on the analysis area of the sample to be processed according to the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com