Fluorine-containing residue removing method, etching method and oxide layer cleaning method

A technology of residue and oxide layer, which is applied in the field of fluorine-containing residue removal and oxide layer cleaning, can solve the problems of increasing device leakage current, device leakage current increase, and affecting the quality of Ti film, so as to reduce leakage current and reduce fluorine Content, the effect of eliminating the bowl-shaped (footing) effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

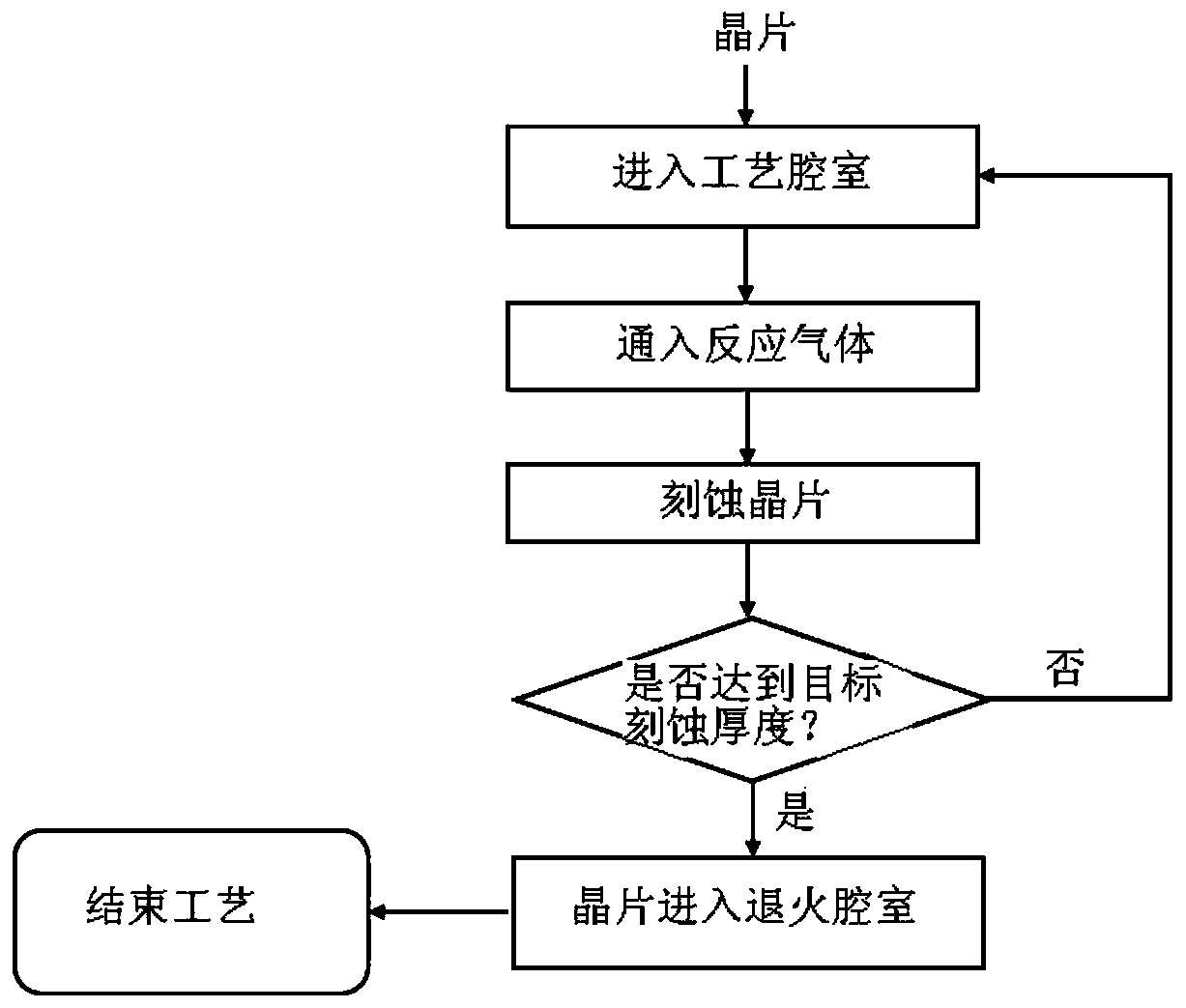

[0046] In order for those skilled in the art to better understand the technical solutions of the present invention, the method for removing fluorine-containing residues, the etching method and the oxide layer cleaning method provided by the present invention will be described in detail below with reference to the accompanying drawings.

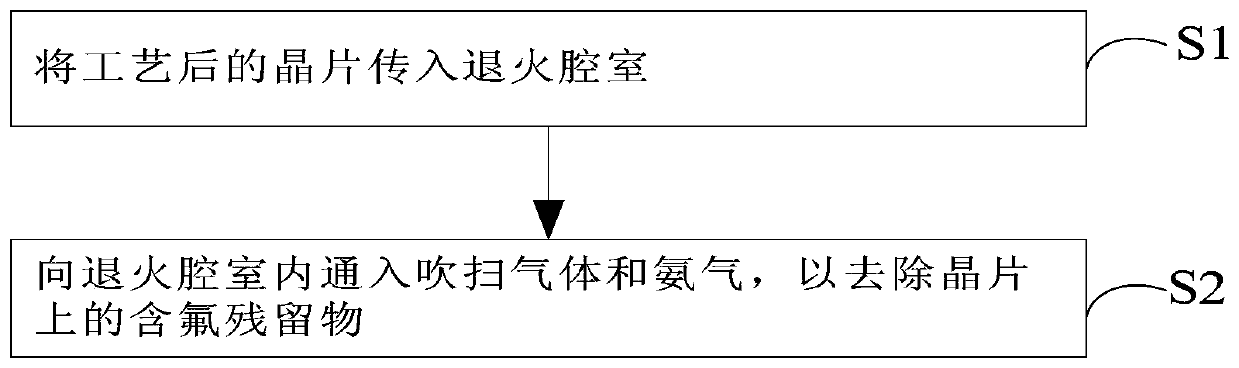

[0047] see figure 1 , an embodiment of the present invention provides a method for removing fluorine-containing residues, which includes the following steps:

[0048] S1, passing the processed wafer into the annealing chamber;

[0049] S2, injecting purge gas and ammonia gas into the annealing chamber to remove fluorine-containing residues on the wafer.

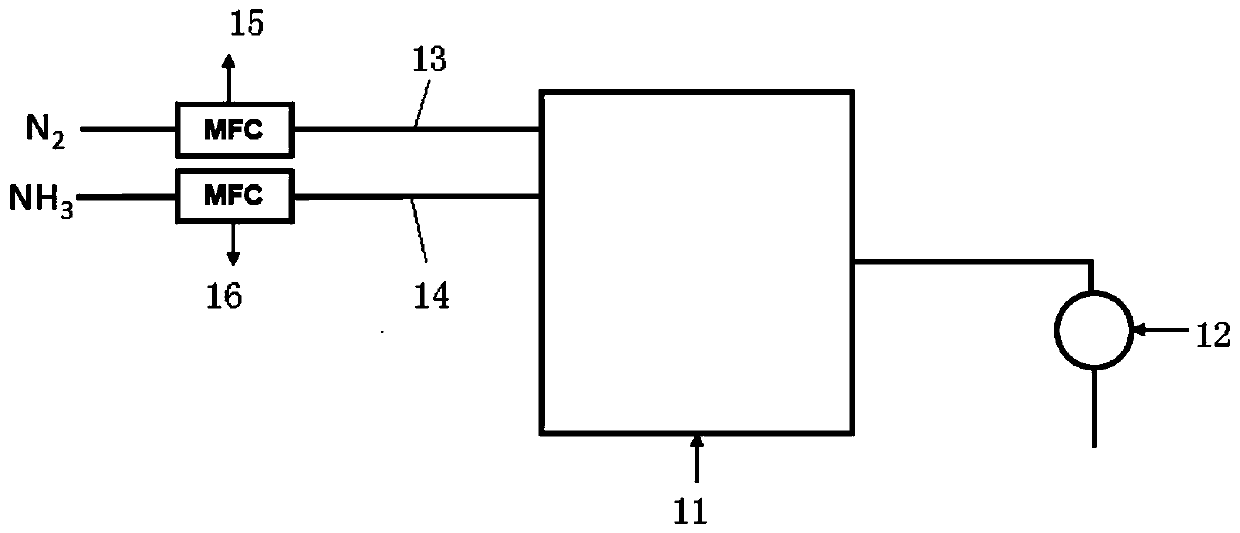

[0050] Specifically, in the present application, residues containing HF remain on the wafer surface after the process, and by passing purge gas and ammonia gas (NH 3 ), NH 3 React with HF to generate solid NH 4 F, then solid NH 4 F is sublimated in the annealing chamber and discharged fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com