Bridge galvanized steel wire clamping device in high frequency fatigue test

A fatigue test, galvanized steel wire technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of difficult operation, laborious and time-consuming, and breakage by one person, and achieve the effect of easy use, guaranteed effectiveness, and not easy to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

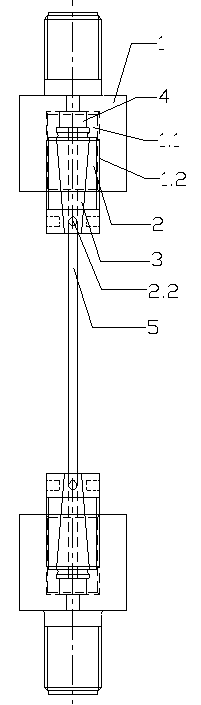

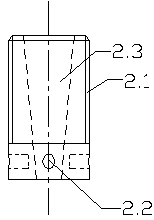

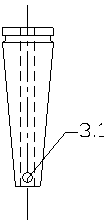

[0026] see Figure 1-4 , the present invention relates to a clamping device for high-frequency fatigue test of galvanized steel wire used for bridges, which includes two oppositely placed bases 1, two riveting barrels 2 and two anchors 3, between the two bases 1 A steel wire 5 is arranged between them, blind holes 1.1 are arranged in the opposite ends of the two bases 1, and internal threads 1.2 are arranged on the inner wall of the blind holes 1.1, and the riveting bucket 2 is cylindrical, and a tapered Hole 2.3, and riveting barrel 2 is provided with external thread 2.1, riveting barrel 2 is arranged in the blind hole 1.1 of base 1 through the cooperation of external thread 2.1 and internal thread 1.2, and one end of riveting barrel 2 close to steel wire 5 is provided with vertical The first through hole 2.2 of the axis of the riveting barrel 2, the first through hole 2.2 passes through the tapered hole 2.3, the two anchors 3 are respectively arranged in the two riveting bar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com