Operating system for circuit boards

An operating system and circuit substrate technology, which is applied in the direction of assembling printed circuits, electrical components, and electrical components with electrical components. Maintenance-friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

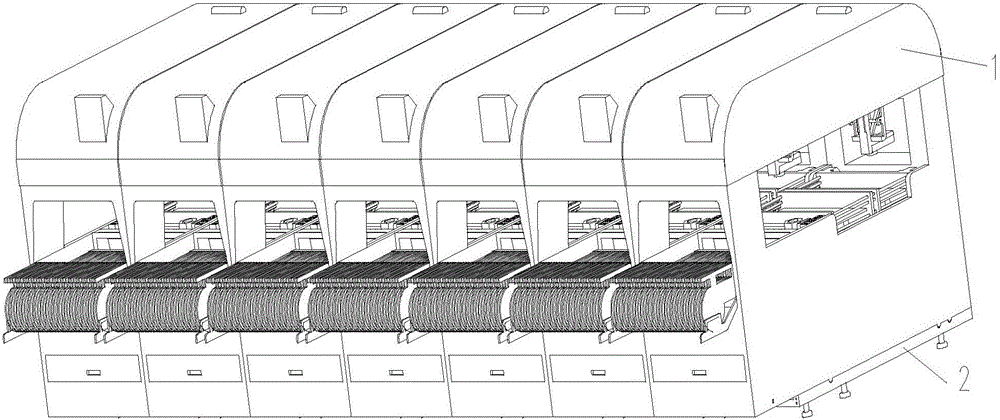

[0041] figure 1 Shown is a production line composed of a plurality of circuit substrate operation systems of the present invention. Each circuit substrate operation system includes the upper module body 1 and the bottom adjustment platform 2. Multiple devices are connected together to form a production line. Minimize the space occupancy. In actual production, the adjustment platform 2 is fixed, and only the module body 1 is adjusted, or the positions of the module bodies 1 are exchanged, and different types of module bodies are exchanged. The present invention is also applicable to High-speed module body and multi-function module body.

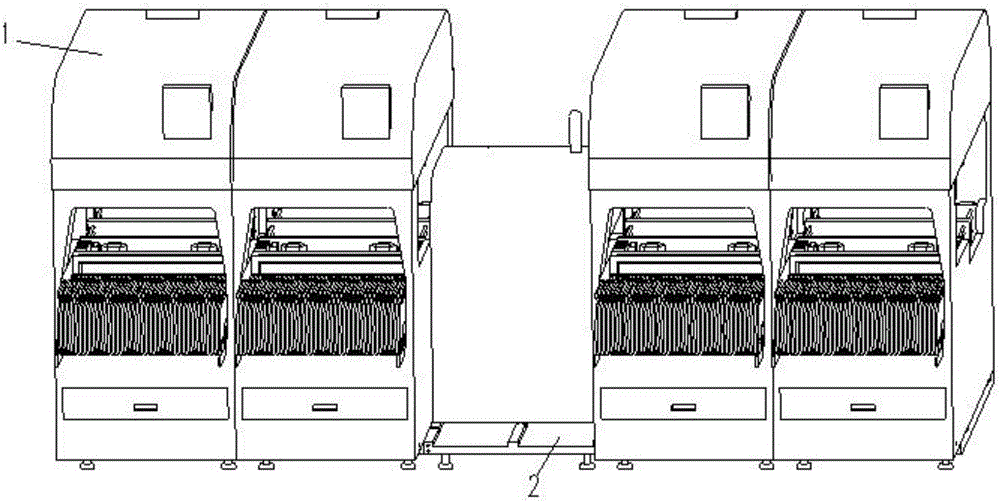

[0042] figure 2 Indicates that after one of the module bodies 1 has a fault problem, the faulty module body 1 can be pulled out, and the adjustment platform 2 is kept in place, and the substrate transmission system, Such as the schematic diagram of the production line behind the docking station. Generally, when a single module body 1 in t...

Embodiment 2

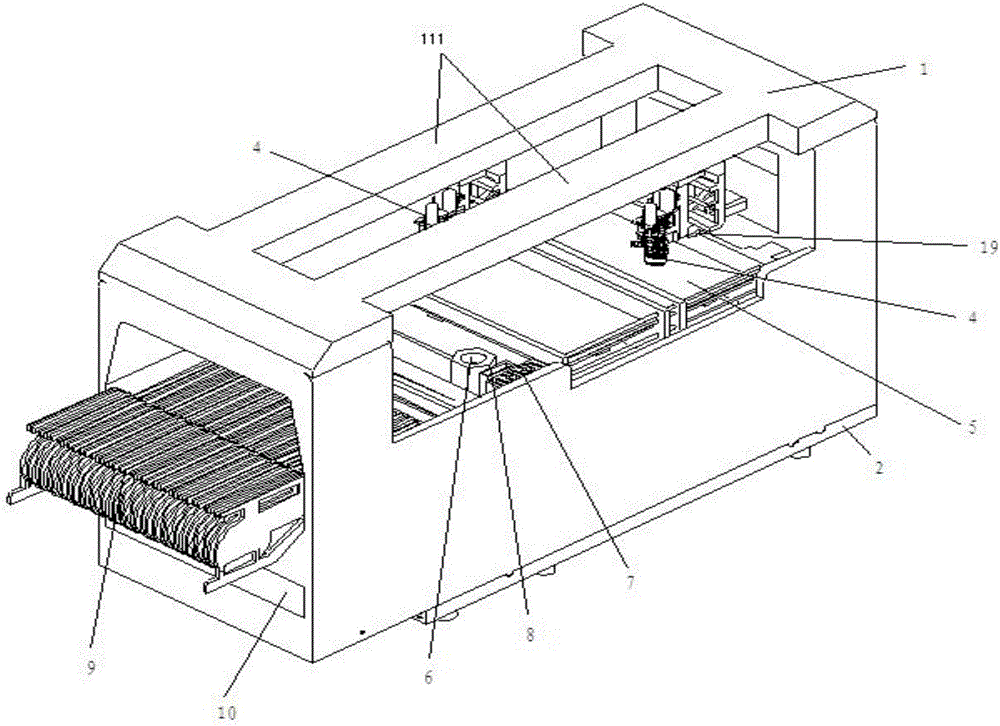

[0053] Figure 14 What is shown is another embodiment of the present invention, which is a multi-functional circuit substrate operation system. The circuit substrate operation system includes a module body 1 and an adjustment platform 2. The module body 1 adopts a single beam and a single paste The module body 1 includes a single beam 111, a multifunctional mounting head 45, a reference camera recognition system 19, a second platform support 46, a substrate transmission system 5, a component camera recognition system 6, a suction Nozzle replacement system 7, waste discarding system 8, and components supply system 9, waste bin 10 for containing waste belt, single crossbeam 111 is connected with the bottom of second platform support 46 and moves along the single crossbeam guide rail, on the second platform support 46 It is equipped with a multi-functional mounting head 45 and a reference camera recognition system 10, and the rest of the structure refers to Embodiment 1, and will...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com