A kind of spring roll leather making machine

A leather making machine and spring roll technology, which is applied to dough forming machinery or equipment, baking, dough forming and cutting equipment, etc. It can solve the problems of low production efficiency, uneven appearance, difficulty in meeting market demand, etc., and reduce material waste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

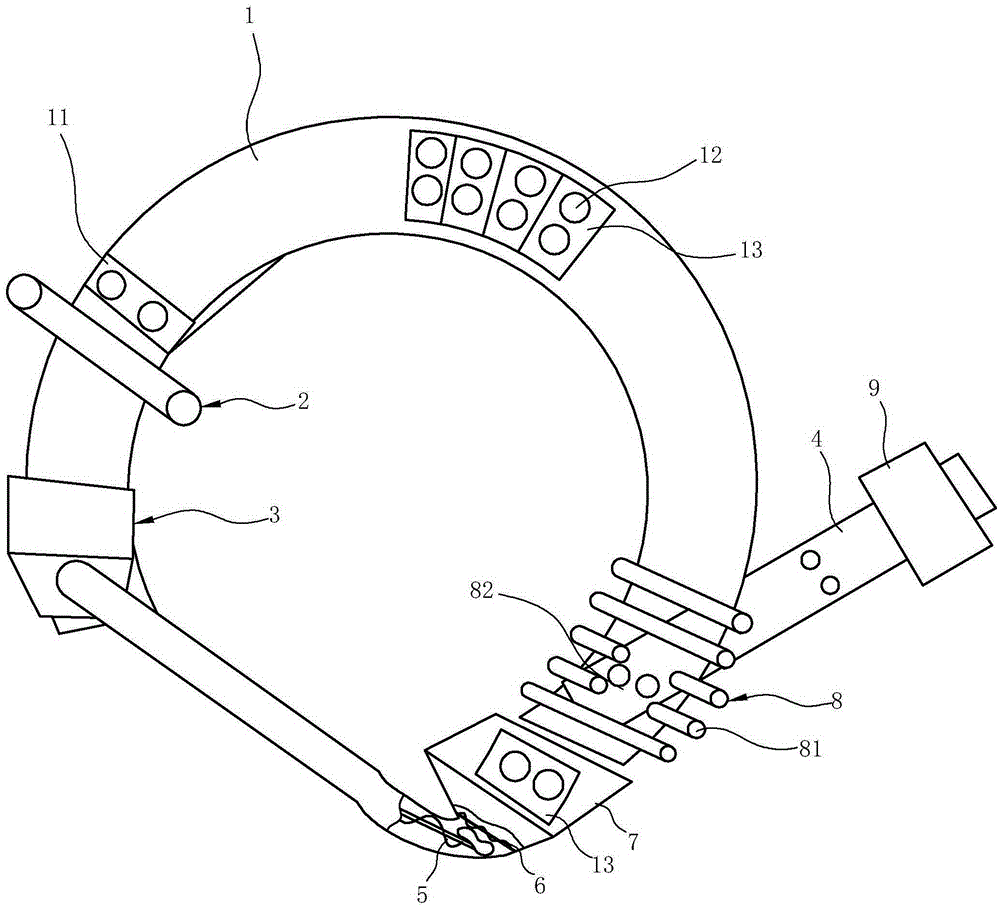

[0016] Such as Figures 1 to 4 As shown, the spring roll leather machine in this implementation includes a fabric bucket 3, extrusion rollers 32, conveyor belt 1, forming roller 2, roller row 8, receiving tank 7, stirring shaft 6, conveying screw 5, conveyor belt 4 And heating furnace 9 etc.

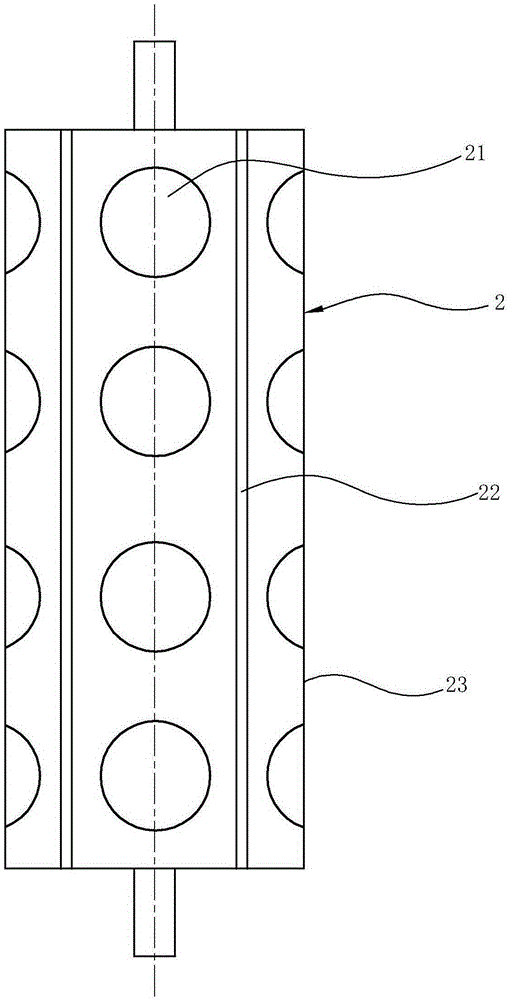

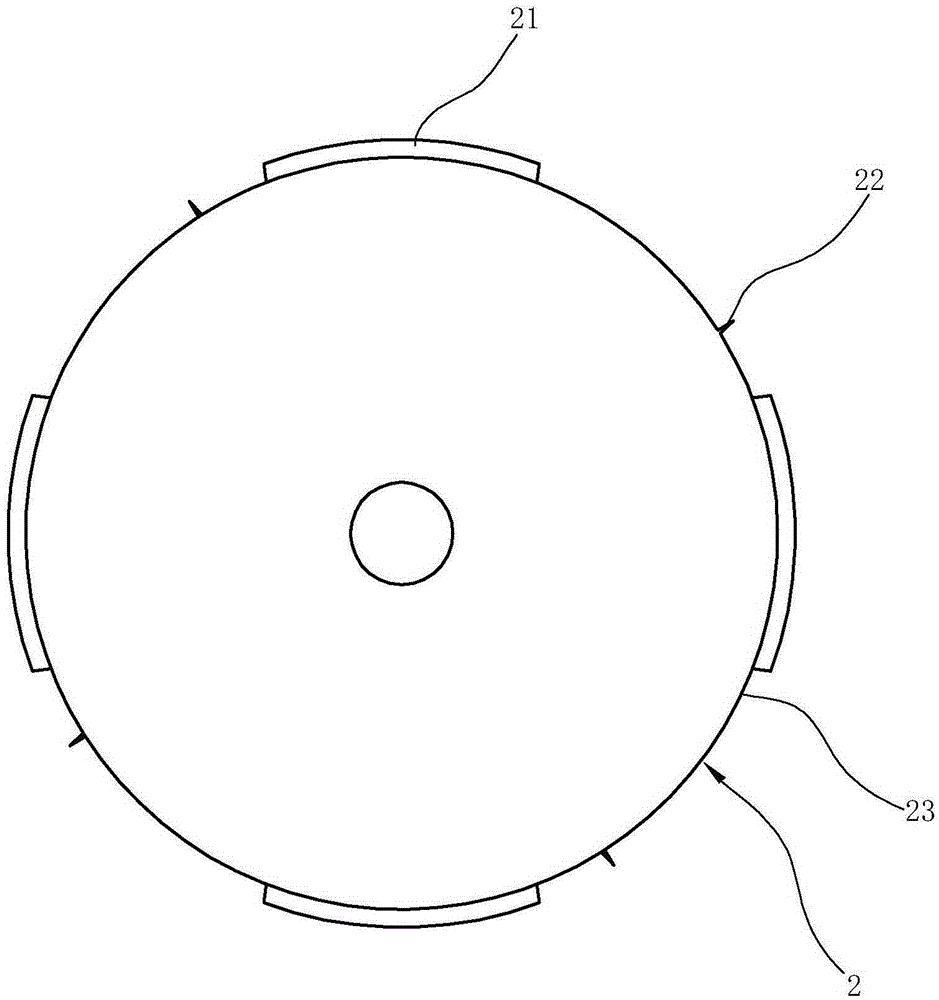

[0017] Wherein, the conveyer belt 1 is arranged below the material bucket 3, and the conveyer belt 1 is circumferential, and the forming roller 2 is arranged on the conveyer belt 1, and the forming cavity 21 is distributed along the axial direction on the forming roller 2, and the forming cavity 21 The cavity wall is higher than the roll surface 23 of the forming roll 2, and a cutting edge 22 is provided along the axial direction of the forming roll 2. The cutting edge 22 is located on both sides of the forming cavity 21, and the cutting edge 22 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com