Novel tire band repairing sheet

A technology for tires and repairing belts, applied in the field of belt repairing sheets, can solve the problems of affecting the time of customers, unable to satisfy customers, and low efficiency of repairing cars in car repair shops, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

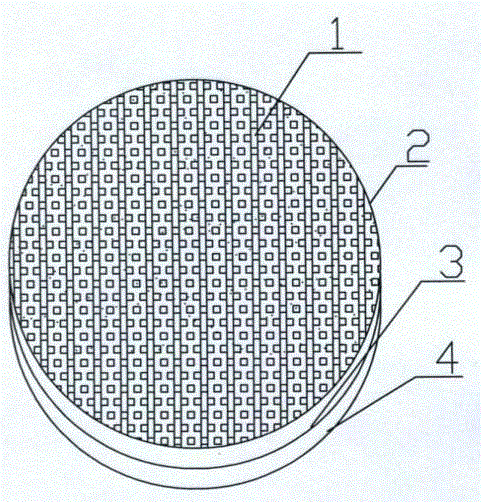

[0010] refer to figure 1 Among them, the present invention includes high elastic soft plastic film 4, wax paper 3, plastic skin 2, high elastic soft plastic film 4 is a strong self-adhesive, and a layer of wax paper 3 is arranged on the upper layer of the high elastic soft plastic film 4 with glue. The upper layer of the wax paper 3 is provided with a hard plastic skin 2, the side of the hard plastic skin 2 in contact with the wax paper 3 is provided with glue, and the hard plastic skin 2 is provided with a layer of iron polishing layer 1. Iron sheet grinding layer 1 is glued on the hard plastic skin 2 by 502. When in use, first polish the puncture with the polishing layer 1, then remove the high-elastic soft plastic film 4 from the wax paper 3, and stick it directly on the puncture of the car belt. The plastic film 4 is drawn into a required shape and pasted on the punctured part of the car belt, which is convenient and time-saving, thereby satisfying the needs of customers ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com