Suspended conveying device for buckets

A conveying device and bucket technology, which is applied to conveyors, transportation and packaging, etc., can solve the problems of bending deformation, large equipment space, large size of chain plates and clamping blocks, etc. The effect of reducing the space occupied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

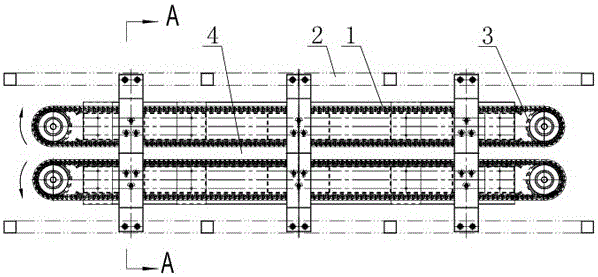

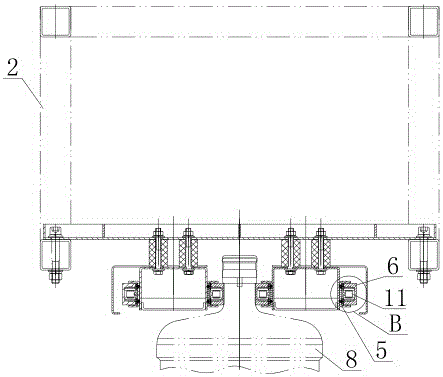

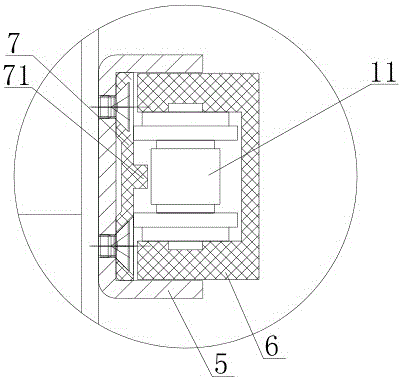

[0012] Such as figure 1 , figure 2 , image 3 As shown, the suspension conveying device of the bucket includes: two clamping chains 1 arranged side by side, each clamping chain 1 is all installed on a pair of sprockets 3 on the mounting frame 2, and the driving device on the mounting frame 2 Driven, the two clamping chains 1 can rotate on the corresponding pair of sprockets 3 respectively. The driving device usually includes a motor, and the rotation of the motor-driven sprocket belongs to the conventional technology in the mechanical field. The connection structure between the wheels and the specific driving process. A conveying channel 4 for buckets is formed between the two clamping chains 1, and a pair of chain-running grooves 5 opening to the outside are provided on the mounting frame 2 between each pair of sprockets 3, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com