Production process of hot-rolled strip for cold-rolling and hot-dip galvanizing

A technology of hot-rolled strip steel, production process, applied in the direction of manufacturing converters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

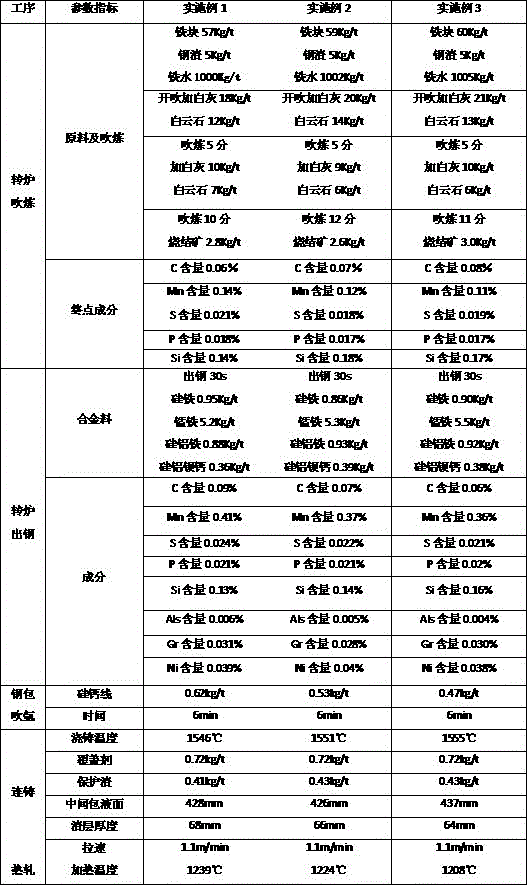

[0022] The present invention will be further described below in conjunction with the examples, and the purpose is only to better understand the content of the present invention. Therefore, the examples given do not limit the protection scope of the present invention.

[0023] In the following examples, the converter is 80t, the steel type is Q195 series, the billet is 165*280, and the hot rolling mill is 650mm.

[0024] Each embodiment sees the following table:

[0025]

[0026] The finished steel strip produced according to the above embodiment exhibits good physical properties and coating properties in the cold-rolled hot-dip galvanizing process, which saves zinc consumption while improving decoration, and has good application and promotion value.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com