High-reliability hydraulic ejector

A hydraulic injector, reliable technology, applied in the direction of mining fluid, wellbore/well components, earthwork drilling and production, etc., can solve problems such as tool failure, tool external damage, nozzle and pressure cap drop, etc., to prevent drop , Improve the reliability of use and the efficiency of construction, and the effect of increasing the number of construction sections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

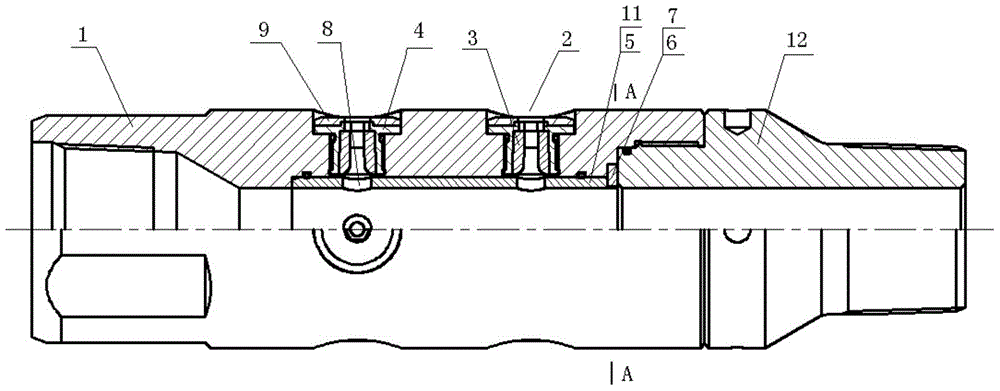

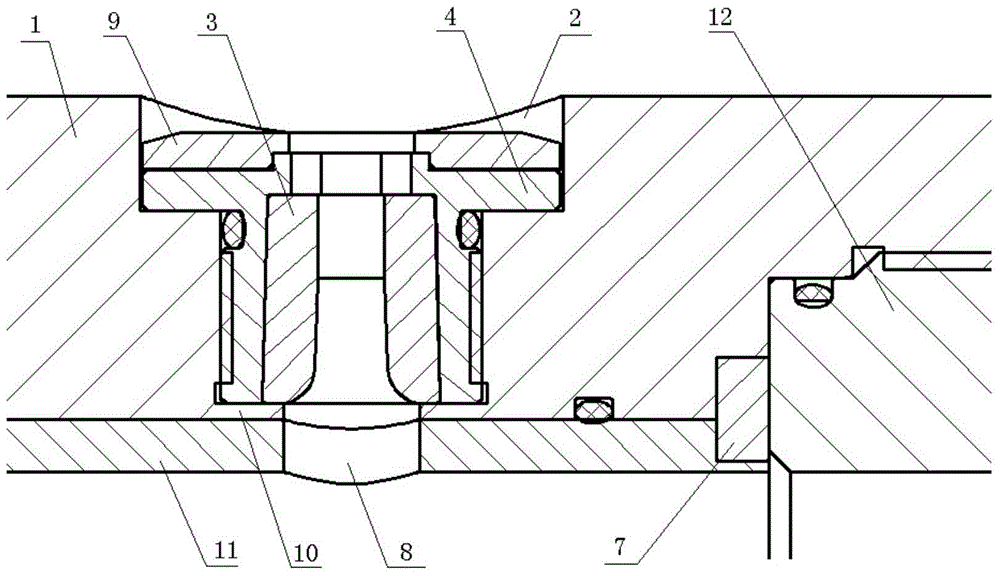

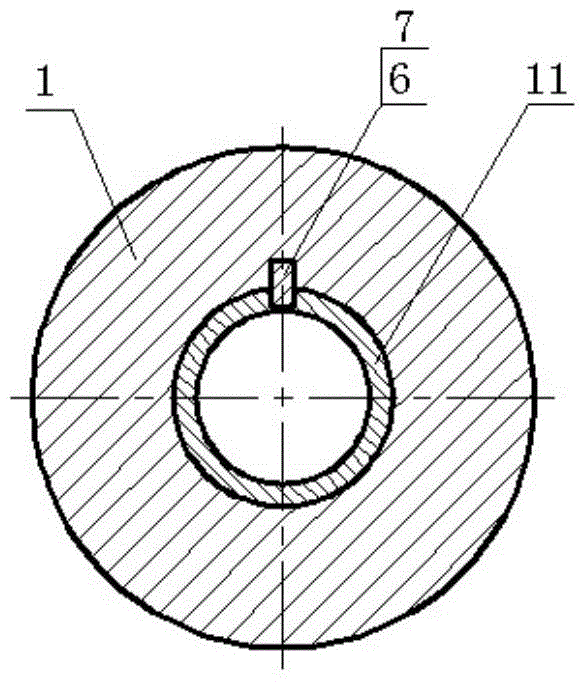

[0013] Combine below figure 1 , 2 , 3 describe an embodiment of the present invention.

[0014] A high-reliability water power injector, comprising a body 1, on which a pressure cap hole 2 is formed, the pressure cap hole 2 is in the shape of a step with a large outside and a small inside, and the small hole at the inner end is an internally threaded hole ; The pressure cap 4 is a stepped shape that matches the shape of the pressure cap hole 2, and its inner hole is a stepped shape that is small on the outside and large on the inside. The nozzle 3 is inserted into the large hole at the inner end, and the small hole at the outer end is an inner hexagon. Used for loading and unloading of the pressure cap 4; the pressure cap 4 is installed in the internal threaded hole at the inner end of the pressure cap hole 2 through the external thread on the outer wall of the small end; the outer end surface of the pressure cap 4 is brazed with a pressure cap 9, and the gland 9 is clamped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com