System and method capable of achieving hydraulic jetting continuous sand filling and layered fracturing

A layered fracturing and hydrojet technology, which is applied in directional wells, horizontal wells, and vertical wells, can solve the problems of not having sand washing function, achieve high construction efficiency, ensure isolation reliability, The effect of increasing the number of construction stages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

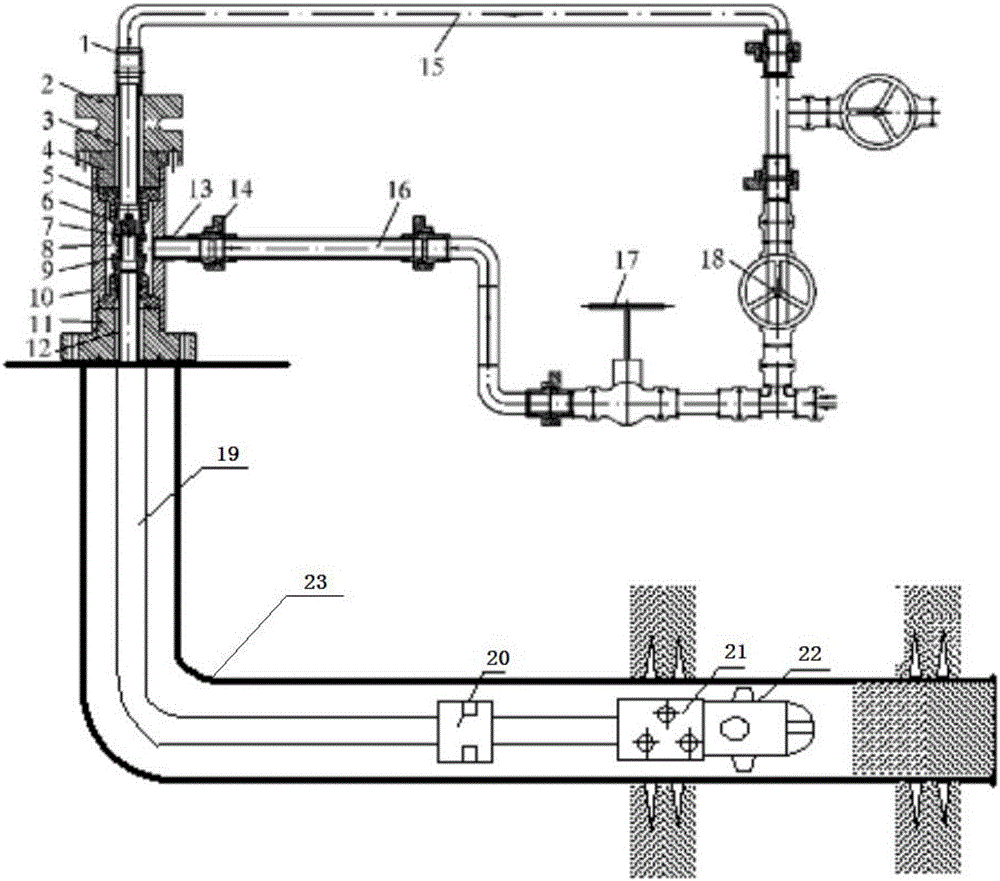

[0028] Such as figure 1 As shown, the embodiment of the present invention provides a system capable of realizing hydraulic jet continuous sand filling layered fracturing, the system includes a downhole process string, and a wellhead continuous sand washing device connected to the upper end of the downhole process string.

[0029] The working principle of the present invention is: by connecting a wellhead continuous sand washing device on the downhole process pipe string, the downhole process is controlled to carry out perforation injection and continuous sand filling, and then the wellhead continuous sand washing device is used for sand washing. The sand seal replaces the bottom seal, which avoids damage to the bottom packer of the pipe string, ensures the reliability of the seal, and improves the number of construction sections of the pipe string and construction safety.

Embodiment 2

[0031] On the basis of Example 1, such as figure 1 As shown, the wellhead continuous sand washing device includes a ring valve body 7; the two ends of the ring valve body 7 are respectively connected with an upper nipple 3 and a lower nipple 12; the inner upper nipple 3 of the ring valve body 7 A central pipe 9 is connected between the lower short joint 12; the upper end of the central pipe 9 is provided with a thread plug 6; an annular space is formed between the central pipe 9 and the ring valve main body 7, and the upper short joint 3 It communicates with the annular space to form a liquid flow channel, and a piston 8 is slidably arranged in the annular space, and the piston 8 is movable to block the liquid flow channel; the upper part of the central tube 9 is provided with a The side hole of the heart tube communicated; the ring valve body 7 is provided with a ring valve side hole communicating with the annular space; the ring valve body 7 is provided with a main body slee...

Embodiment 3

[0039] On the basis of Embodiment 1, the downhole process string includes a casing 23, an oil pipe 19 arranged in the casing 23, a safety drop 20 is connected to the lower end of the oil pipe 19, and a safety drop 20 is connected to the lower end of the safety drop 20 through a pipeline. The injector 21 is connected with a pilot check valve 22 at the lower end of the injector 21 . The process is simple in structure and convenient in construction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com