Body paper-free two-layer temperature-sensitive printing label

A linerless, thermal printing technology, applied in the field of labels, can solve the problems of package damage, increase the return rate, time-consuming and labor-intensive, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

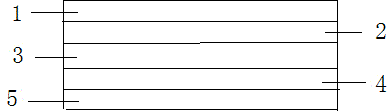

[0010] see figure 1 , a two-layer thermal printing label without a backing paper, is characterized in that it mainly includes a silicone oil layer 1, a thermal paper 2, an adhesive layer A 3, a bottom layer 4, and an adhesive layer B 5 arranged in sequence and bonded together; wherein, The silicone oil layer is on the front side of the thermal paper after printing, the glue layer 3 is on the back of the heat sensitive layer (that is, the reverse side of the printing surface), and the glue layer 3 and the glue layer 5 are on both sides of the bottom layer respectively.

[0011] The middle layer is 28g-60g film or paper per square meter, with glue on one side.

[0012] The two-layer heat-sensitive printing label without bottom paper is composed of two or more connected ones, and each printing label is connected by a tear line, and then rolled into a roll with a paper tube.

[0013] The silicone oil layer 1 is coated with 1 g / ㎡-1.4 g / ㎡ of silicone oil, which has the effect of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com