Ground wire special for middle switch cabinet

A grounding wire and switch cabinet technology, which is applied in the field of special grounding wires for central switch cabinets, can solve the problems of cumbersome, time-consuming and labor-intensive grounding for central cabinets, and grounding wires, and achieve clear grounding points, convenient use, and grounding good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

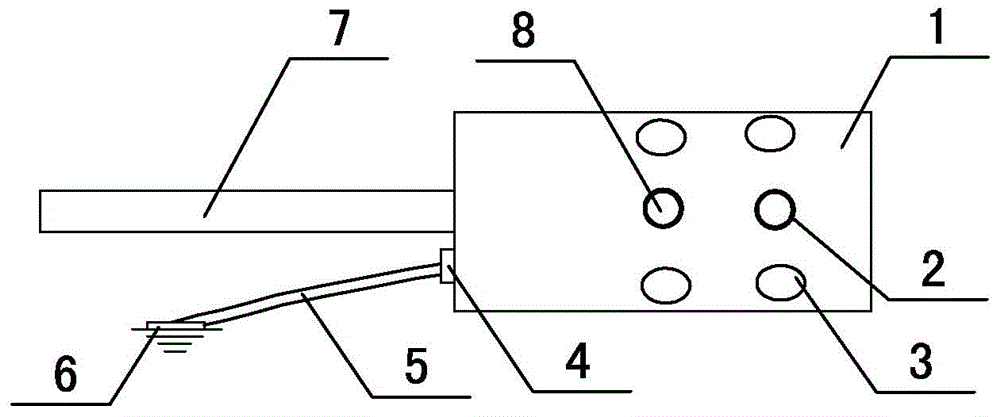

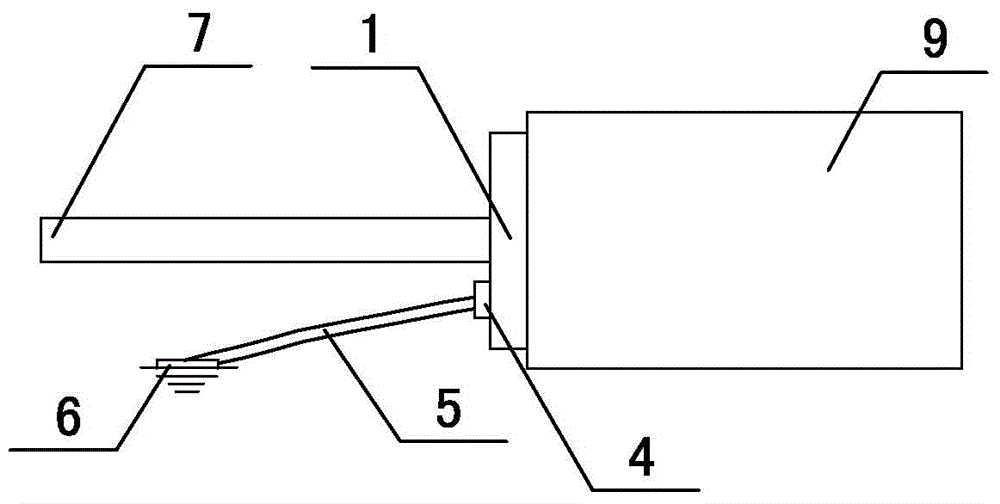

[0020] Such as Figure 1-2 As shown, the special grounding wire for the central switch cabinet of the present invention is composed of a grounding wire clip 6, an annealed grounding copper wire 5, an insulating operating rod 7 and a metal head, and a cylindrical aluminum metal head 1 is arranged on the top of the insulating operating rod 7. The insulating operating rod 7 is tightly crimped on the cylindrical aluminum metal head 1, and the cylindrical aluminum metal head 1 is ring-shaped and uniformly arranged with two rows of corresponding contact holes 2, and the inside of the contact hole 2 is provided with elastic metal ball contacts 8 , between the two contact holes 2 in each row is a fixing hole 3, the lower static contact 9 in the central switch cabinet is provided with a protrusion corresponding to the fixing hole 3, and the bottom of the cylindrical aluminum me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com