A frog feeding machine

A feeding machine and frog technology, applied in animal husbandry and other directions, can solve the problems of limiting the efficiency of artificial breeding of frogs, low feeding efficiency of young frogs, and inability to eat young frogs, so as to overcome the low efficiency of artificial breeding, shorten the growth cycle, and improve the The effect of eating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

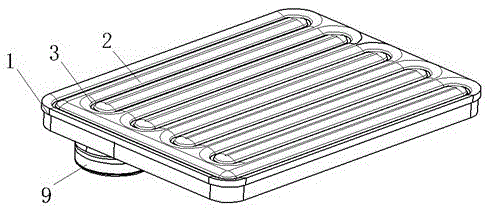

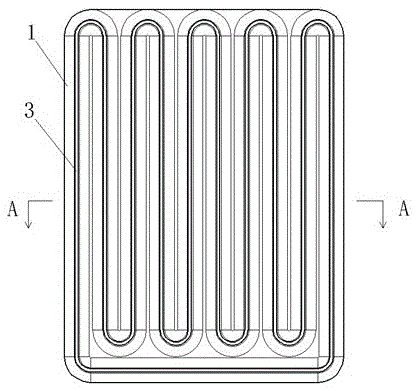

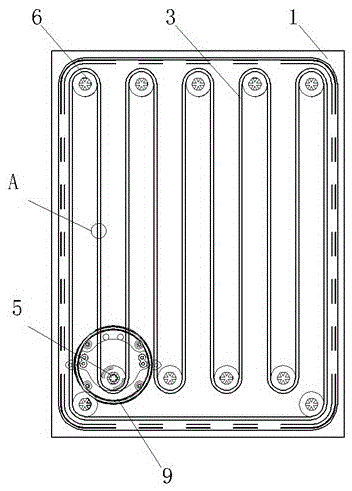

[0043] Frog feeding machine of the present invention, its structure is as figure 1 As shown, the body 1 is included, and the body 1 is composed of an upper panel 7 and a lower panel 8 (as Figure 5 As shown), the inside of the body 1 has a cavity structure. The surface of the upper panel 7 is a plane structure as a whole, and is provided with a food trough 2, and the food trough 2 is reciprocally arranged on the feeding surface of the upper panel 7 to expand the distribution area of the food trough 2 on the upper panel 7. In the embodiment, a continuous "S" shape arrangement is adopted, and the food trough 2 is connected from end to end to form a closed food circuit (such as figure 2 shown), the eating surface between two adjacent food troughs is an arc-shaped convex structure (such as Figure 5 shown). Described food trough 2 is provided with the food transmission belt 3 that is provided with along food trough 2 paths (such as figure 2 , image 3 and 5As shown), the...

Embodiment 2

[0049] Frog feeding machine of the present invention, its structure is as figure 1 As shown, the body 1 is included, and the body 1 is composed of an upper panel 7 and a lower panel 8 (as Figure 5 As shown), the inside of the body 1 has a cavity structure. The surface of the upper panel 7 is a plane structure as a whole, and is provided with a food trough 2, and the food trough 2 is reciprocally arranged on the feeding surface of the upper panel 7 to expand the distribution area of the food trough 2 on the upper panel 7. In the embodiment, a continuous "Z" arrangement is adopted, and the food troughs 2 are connected from end to end to form a closed food loop, and the eating surfaces between the adjacent food troughs 2 are arc-shaped convex structures (such as Figure 5 shown). In the food trough 2, be provided with the food transmission belt 3 (such as figure 2 and 5 As shown), the body 1 is provided with a transmission system that cooperates with the food material tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com