A kind of black sea bream feed and preparation method thereof

A technology for feed and black sea bream, which is applied to the field of black sea bream feed and its preparation, can solve the problems that black silk feed has not been reported, and there is little research on astragalus fodder, etc., and can achieve the ability of juvenile fish to actively resist stress and attract food. Good, high digestion and absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

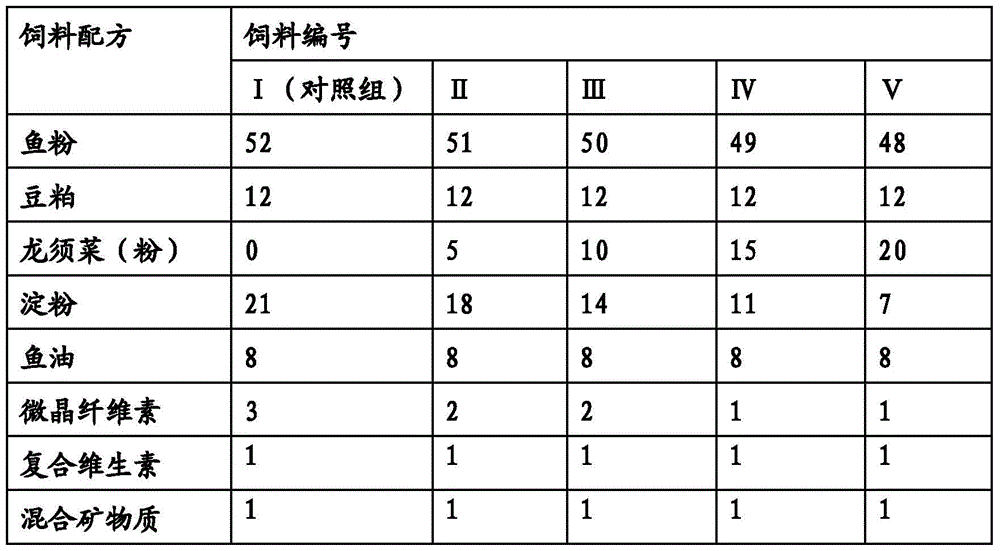

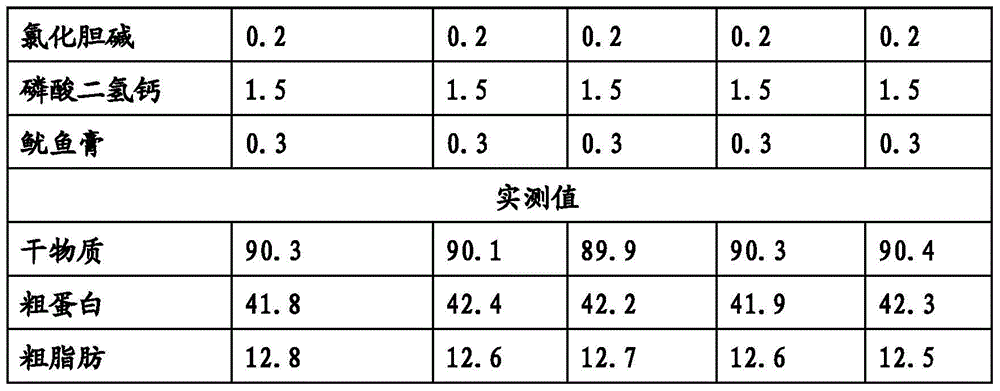

[0021] In order to detect the most suitable addition amount of asparagus, the black sea bream compound feed was made by adding 0 (control), 5%, 10%, 15%, 20% of asparagus dry powder instead of fish meal or other plant protein sources. Feed formula is as shown in table 1 (value is percentage by weight), and preparation steps are as follows:

[0022] ①Collect fresh asparagus, wash it, remove impurities, and dehydrate it with a centrifugal dehydrator. The speed of the centrifugal dehydrator is 3000-5000 rpm, and the centrifugal dehydration is 3-10 minutes.

[0023] ②Preparation of asparagus powder: put the dehydrated asparagus in a drying oven to dry, set the drying temperature to 70-85°C, and set the drying time to 4-5 hours, and control the moisture content of the dried asparagus at 10-15%, and then pulverized to 80-120 mesh with a pulverizer, and set aside.

[0024] ③Mixing: According to the feed formula shown in Table 1, crush the lump protein source raw materials and sugar ...

Embodiment 2

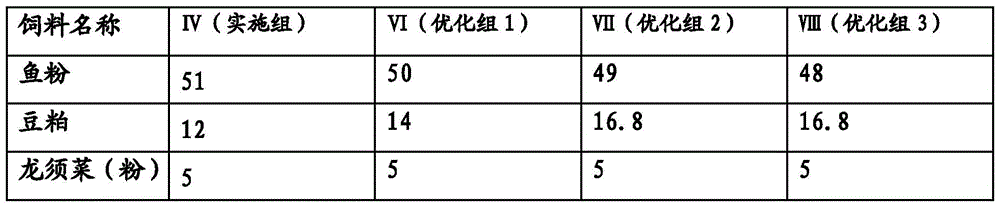

[0028] In order to obtain the best feed formula for black sea bream containing asparagus, on the basis of asparagus content of 5%, the ratio of raw materials and auxiliary materials was adjusted to make different black sea bream compound feeds. The feed formula is shown in Table 2 Show (numerical value is percentage by weight), preparation step is with embodiment 1.

[0029] Table 1

[0030]

[0031]

[0032] Note: a. Starch and soybean meal are commercially available products, which can be purchased from the domestic raw material market;

[0033] b. The fish meal is American fish meal, with a crude protein content of 68% and a fish oil content of 9.4%;

[0034] c. Asparagus powder protein content is 19.14%, fat content is 0.5%, crude fiber content is 5.8%, ash content is 28.77%, amino acid content (g / 100g, dry weight): threonine (Thr)*0.70, valine Acid (Vla)*1.11, Methionine (Met)*0.53, Isoleucine (Ile)*0.94, Leucine (Leu)*1.32, Phenylalanine (Phe)*0.83, Lysine (Lys)*...

Embodiment 3

[0040] With the formulated feed prepared in Example 1, approximately 9.8 g of black sea bream were raised. Present embodiment is the net cage culture that fish raft is carried out in sea, and culture net cage is 1 * 1 * 1.5m, has cover net, in order to escape and waterfowl. Three parallel experiments were performed in each group, and 30 fish were tested in each parallel experiment. During the breeding period, the temperature was 20-26° C., and the salinity was 27-31 degrees. After 60 days of cultivation, various growth indicators were measured. The results of Example 1 are shown in Table 3.

[0041] table 3

[0042] group

[0043] Note: The data are mean ± standard error; PPV: protein deposition rate; FER: feed conversion rate In peer data, those without the same lowercase letters indicate significant differences (P<0.05)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com