A Method of Using Gradient Arrangement of Cooling Water Nozzles to Control Roll Profile Thermal Crown

A technology of cooling water and control rollers, applied in the direction of profile control, etc., to reduce the possibility of accidents, reduce scrap rate, and improve quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

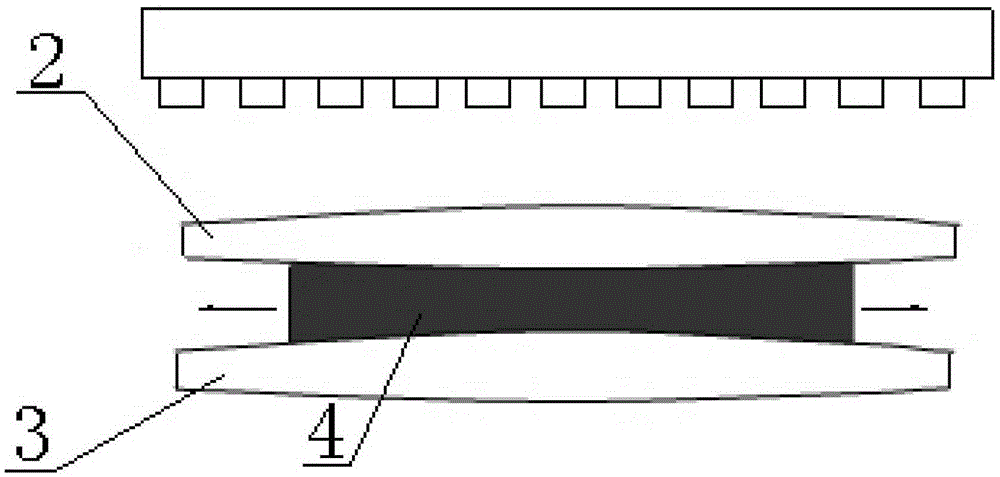

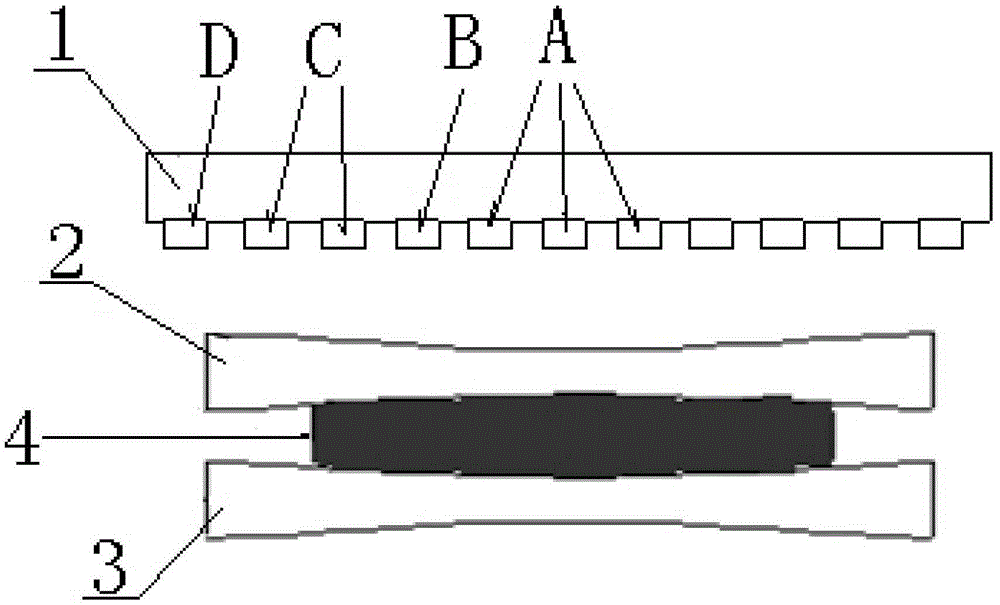

[0030] Such as image 3 As shown, a method for controlling the thermal crown of a roll profile by utilizing the gradient arrangement of cooling water nozzles, the cooling water nozzle group 1 is arranged above the roll 2 on the rolling stand of the rolling mill;

[0031] The cooling water nozzle group is located in the middle position of three main cooling water nozzles A arranged side by side, one auxiliary cooling water nozzle B is respectively arranged on both sides of the main cooling water nozzle, and two auxiliary cooling water nozzles are arranged Two secondary cooling water nozzles C are installed on the side, and finally one terminal cooling water nozzle D is installed at both ends of the entire cooling water nozzle group;

[0032] Redistribute the water spray volume of each water nozzle of the cooling water nozzle group, among which the water spray volume of the main cooling water nozzle A is the largest, the water spray volume of the secondary cooling water nozzle B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com