Eccentric tool fine-adjustment mechanism

A fine-tuning mechanism and eccentric technology, which is applied in tool holders, manufacturing tools, accessories of tool holders, etc., can solve problems affecting the stability of tool holders, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

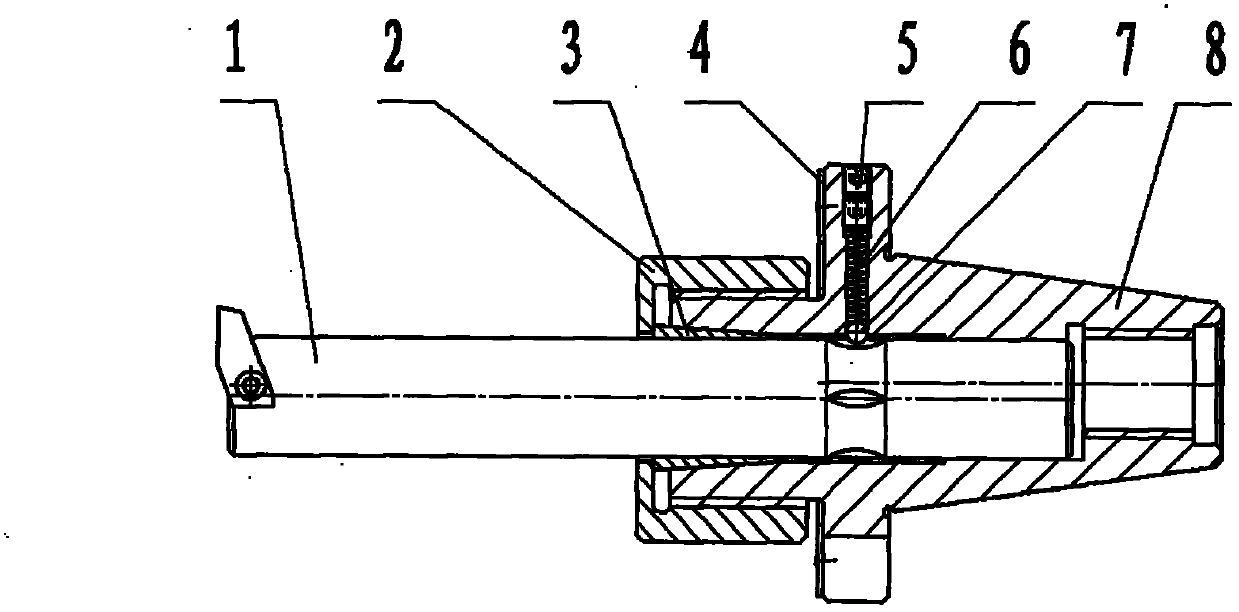

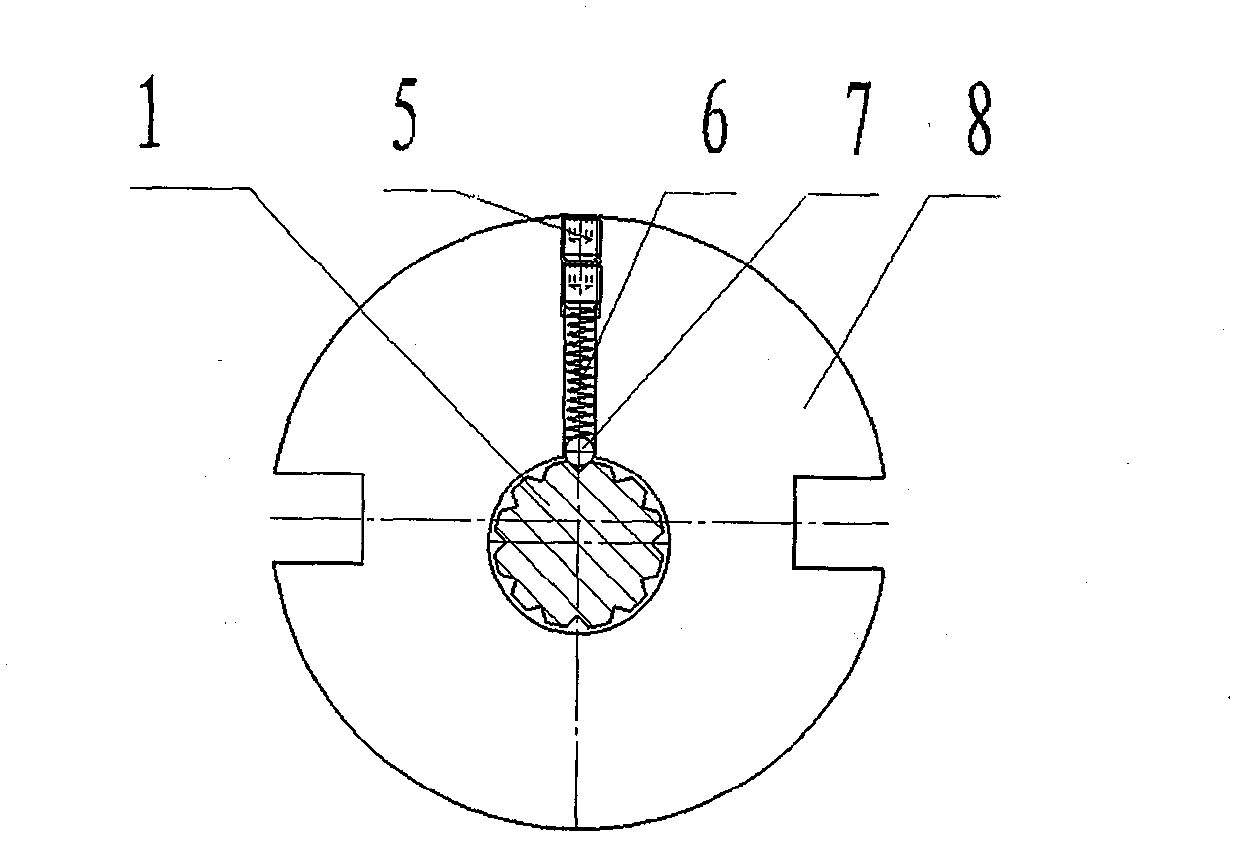

[0007] Referring to the accompanying drawings, the present invention provides an eccentric tool fine-tuning mechanism for part hole machining, including a tool bar 1, a lock nut 2, an elastic taper sleeve 3, an indicator plate 4, a set screw 5, a compression spring 6, a positioning Steel ball 7, knife seat 8.

[0008] One end of the eccentric tool fine-tuning mechanism knife rod 1 is equipped with a detachable blade, and the other end is closely matched with the cylindrical inner hole of the tool holder 8. The inner hole of the tool holder 8 is designed with an eccentricity with the reference outer circle, and the elastic cone The cone of cover 3 cooperates with the end taper hole of knife seat 8, and the inner cylindrical hole of elastic taper sleeve cooperates with knife bar 1.

[0009] The lock nut 2 is threadedly connected to the tool seat 8 , and the end surface of the inner hole of the lock nut 2 is pressed against the large end surface of the elastic taper sleeve 3 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com