Blind hole bearing outer ring detachment puller

A bearing outer ring and pulling tool technology, which is applied in the field of bearing assembly, can solve the problems of difficulty in repairing and disassembling the bearing outer ring, and achieve the effects of easy promotion, simple operation and saving manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

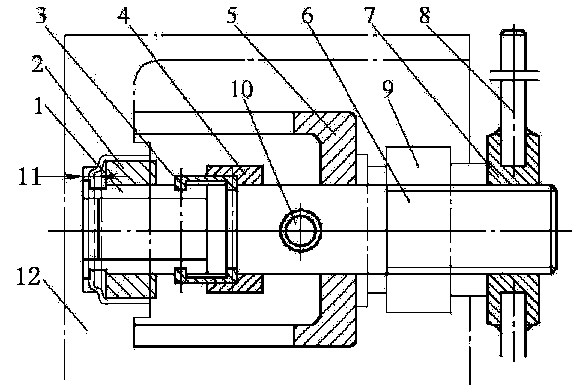

[0010] Below in conjunction with the accompanying drawings, the present invention will be further described; a puller for removing the outer ring of a blind hole bearing, such as figure 1 As shown in , it includes pulling block 1, positioning block 2, coupling block 3, locking ring 4, support frame 5, screw shaft 6, round nut 7, twisting hand 8, release bearing 9 and ejector rod 10; among them, the coupling block 3 is a semicircle, the inner hole of the pull block 1 is in dynamic fit with the outer circle of the front end of the screw shaft 6, the outer circle of the front end of the screw shaft 6 is in dynamic fit with the positioning block 2, and the wrench 8 is fixed on the screw shaft 6 through the round nut 7 , the thread at the rear end of the screw shaft 6 can adopt a fine pitch, so that the round nut 7 can be multi-threaded under the condition of not thickening, a deep hole is drilled in the middle of the screw shaft 6, and the ejector rod 10 is inserted into the screw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com