Method for designing efficient duct

A design method and catheter technology, applied in shipbuilding, ship propulsion, ships, etc., can solve the problems of high efficiency of full-turn propellers, no design method, etc., and achieve the effect of fast design method and high calculation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

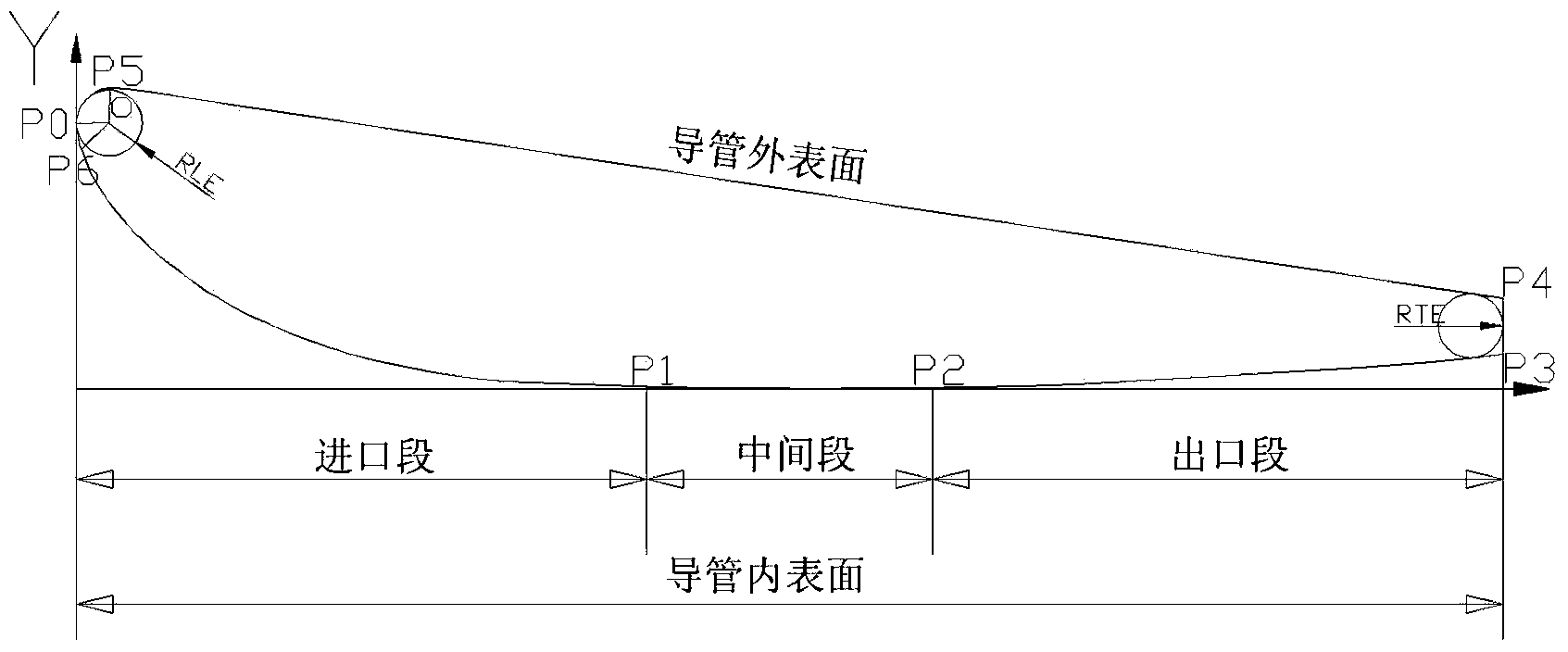

[0043] Such as figure 1 As shown, the catheter line type is divided into the inner surface of the catheter and the outer surface of the catheter, wherein the inner surface of the catheter is divided into the inlet section of the catheter, the middle section of the catheter, and the outlet section of the catheter. In order to finely express the catheter line type, P0(x0,y0), P1(x1,y1), P2(x2,y2), P3(x3,y3), P4(x4,y4), P5(x5,y5 ) and P6(x6,y6) seven control points. The inner surface of the catheter is controlled by a total of five points P0, P6, P1, P2, and P3, while the outer surface of the catheter is controlled by three points P0, P5, and P4. The slopes of the control points P1, P2, P3, P4, P5, and P6 are k1, k2, k3, k4, k5, and k6, respectively.

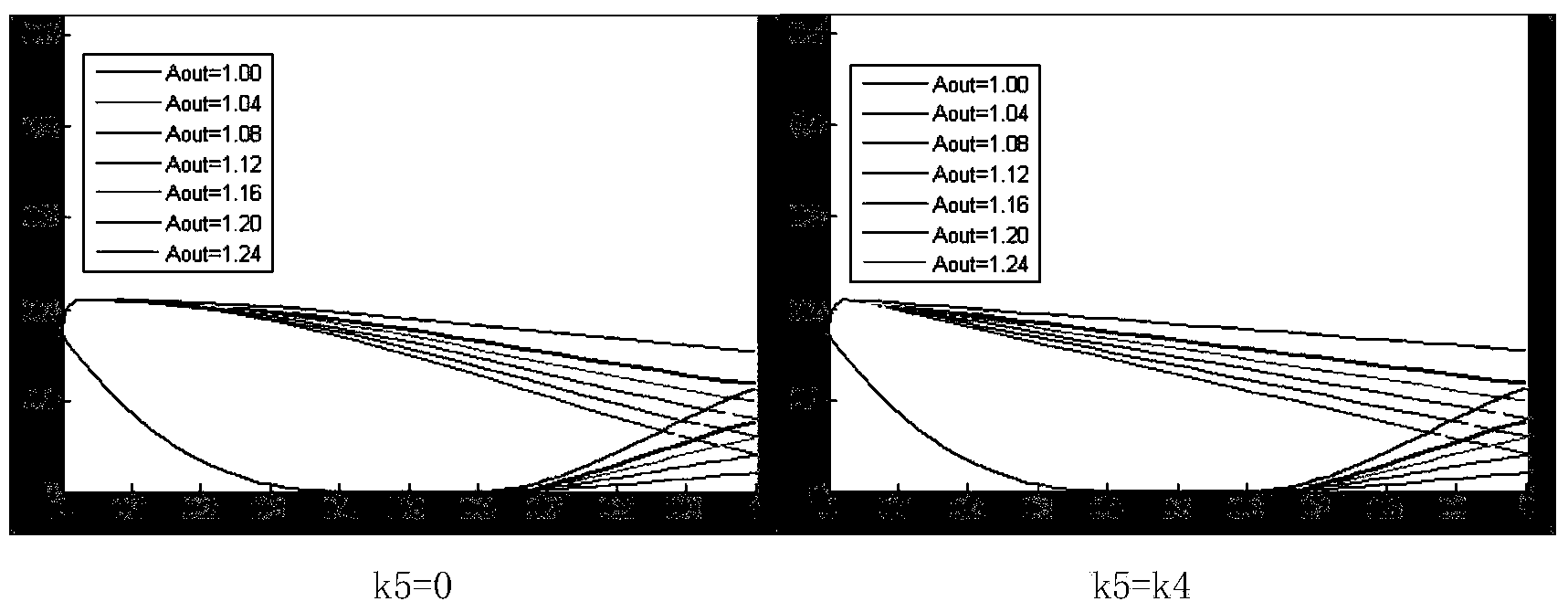

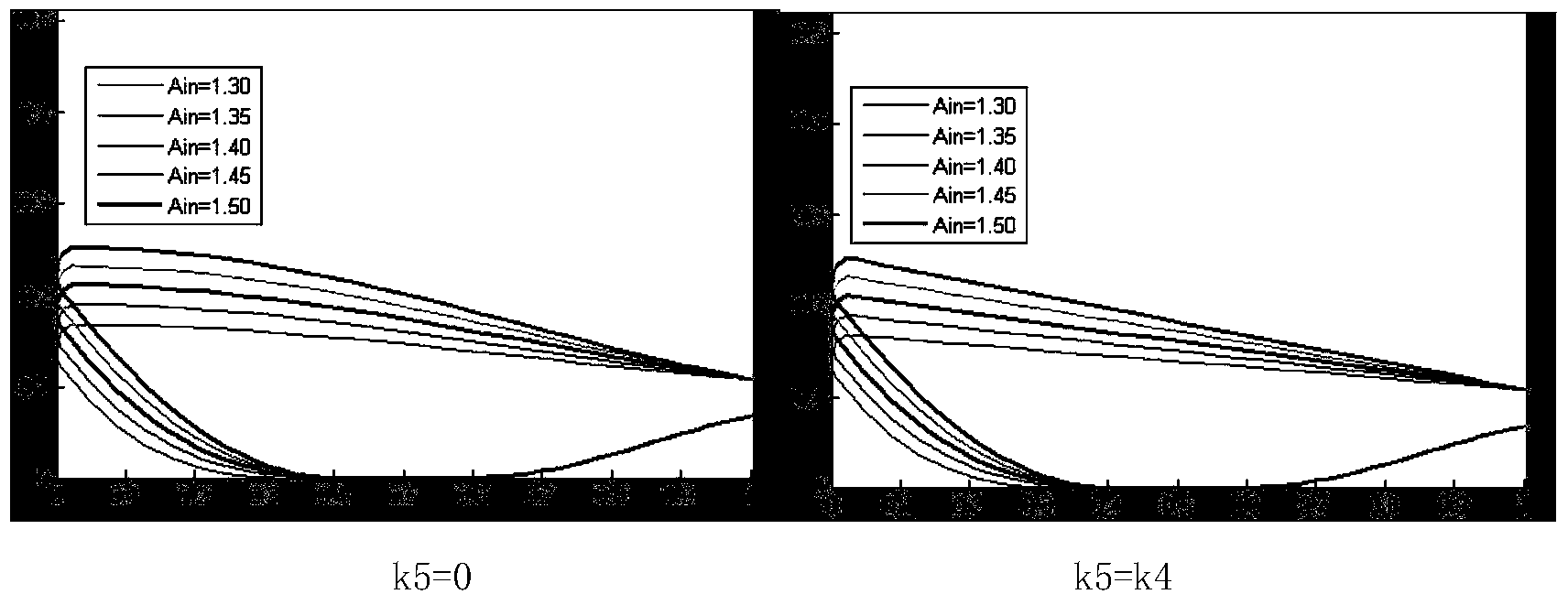

[0044] The duct inlet area coefficient Ain, the duct exit area coefficient Aout, the guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com