Fiber filling device

A filling device and technology of a filling device, applied in the direction of transportation and packaging, conveying bulk materials, conveyors, etc., can solve the problems of potential safety hazards for operators, loud noise, machine stoppage, etc., and achieve environmental protection and safety of the working environment and reduce noise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific implementation process of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0013] In this embodiment, the fiber filling device is used in pillow filling equipment as an example, and it can also be used in filling equipment such as filling quilts and down jackets.

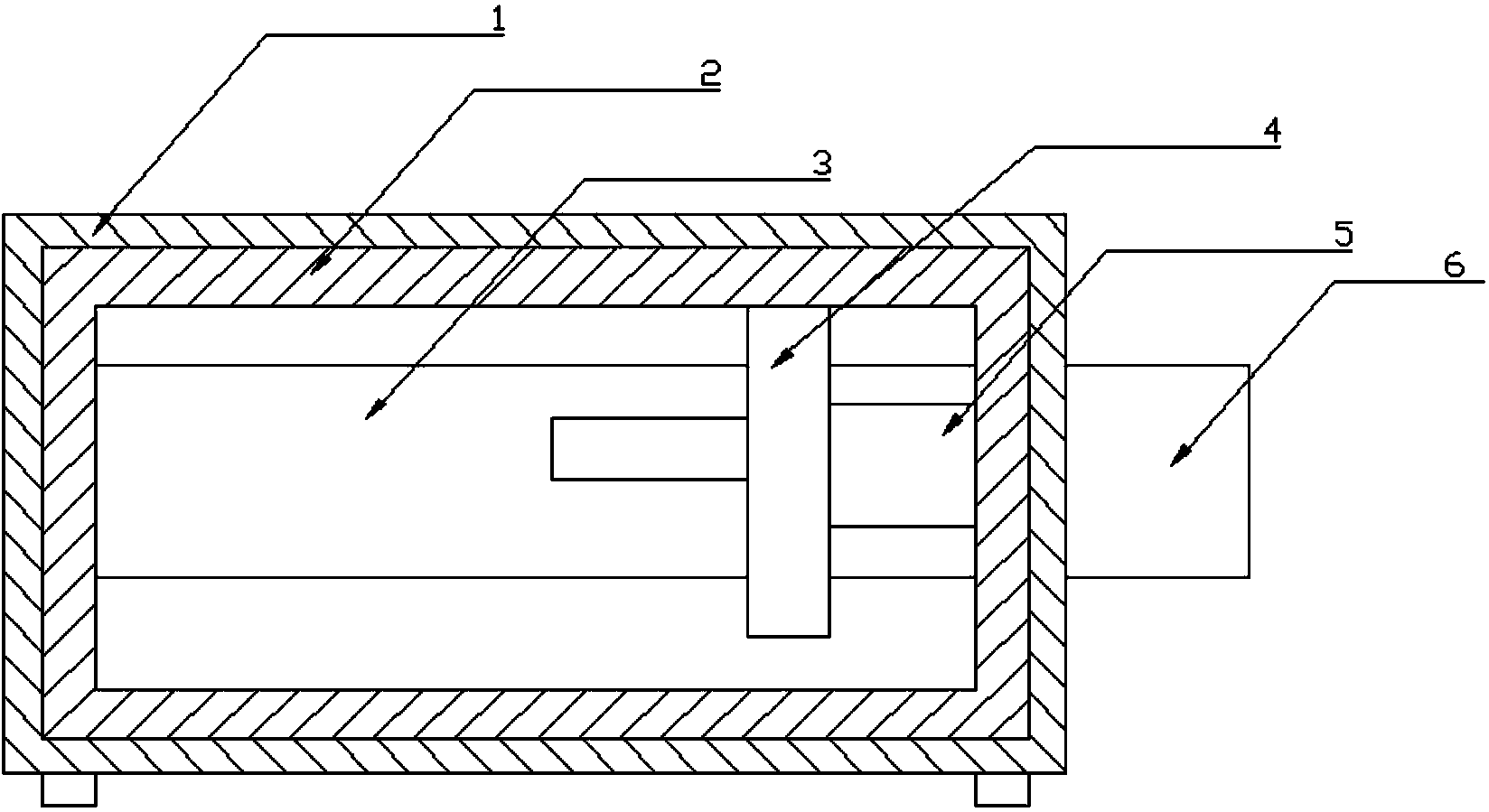

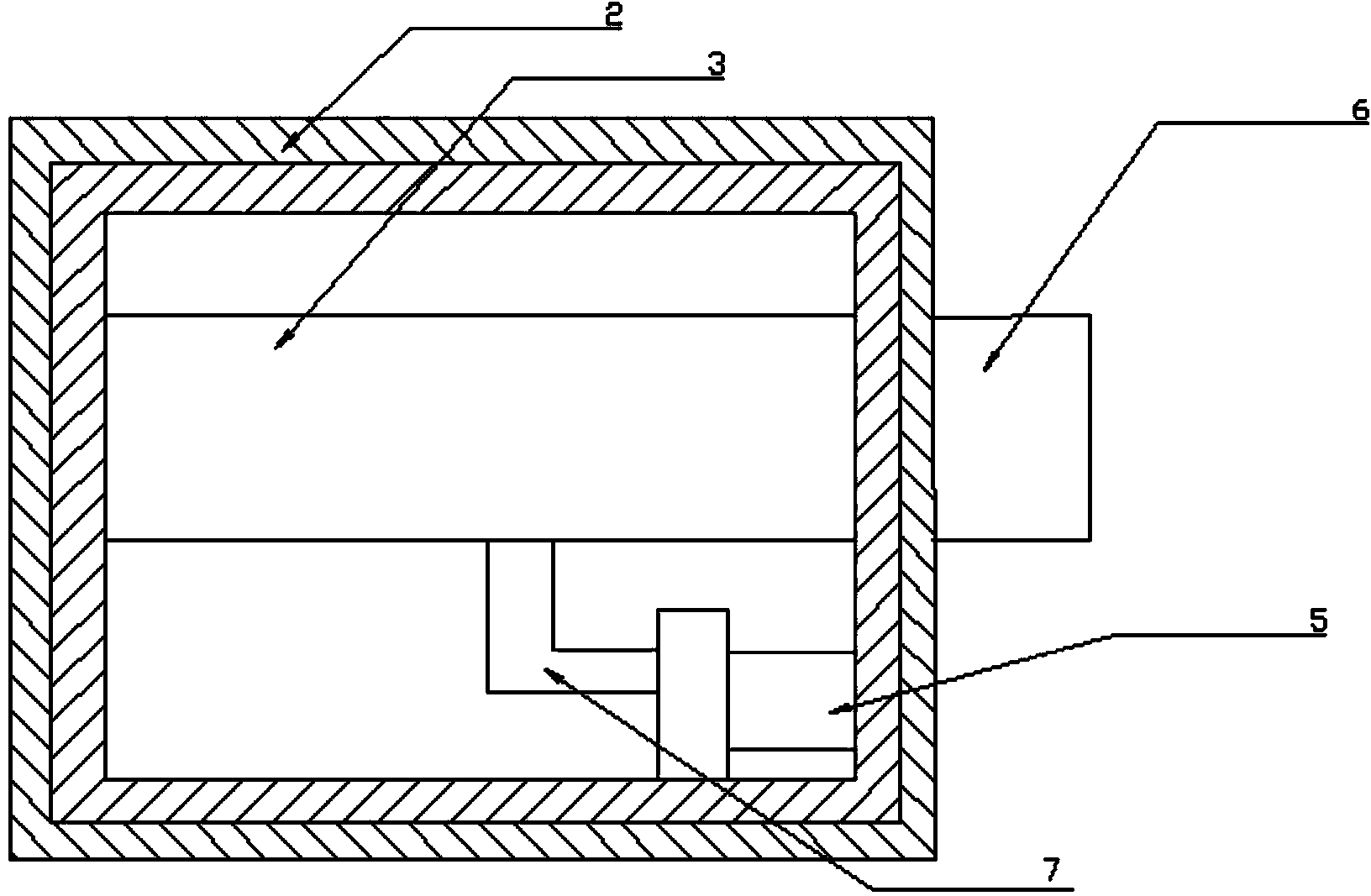

[0014] Such as figure 1 The fiber filling device shown is a part of the entire pillow filling equipment. Its front end is connected to the conveying track of the pillow filling cotton, and the rear end is connected to the pillow bag fixing device. In this embodiment, the pillow filling cotton is transported in two channels to the pillow pocket fixture.

[0015] Such as figure 1 and figure 2 The shown fiber filling device comprises a filling pipeline 3 and a cotton conveying fan, and the many cotton conveying fans include a motor 5, centrifugal fan blades 4 and an air outlet duct 7, and the air outlet of the cotton conveying fan is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com