Anchor pipe cable supporting structure capable of bearing lateral shear force

A supporting structure and transverse shearing technology, which is applied in the installation of anchor rods, mining equipment, earthwork drilling and mining, etc., can solve the problems of excessive deformation of surrounding rock, shearing and pulling of anchor rods and cables, etc., and achieves remarkable results. Obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

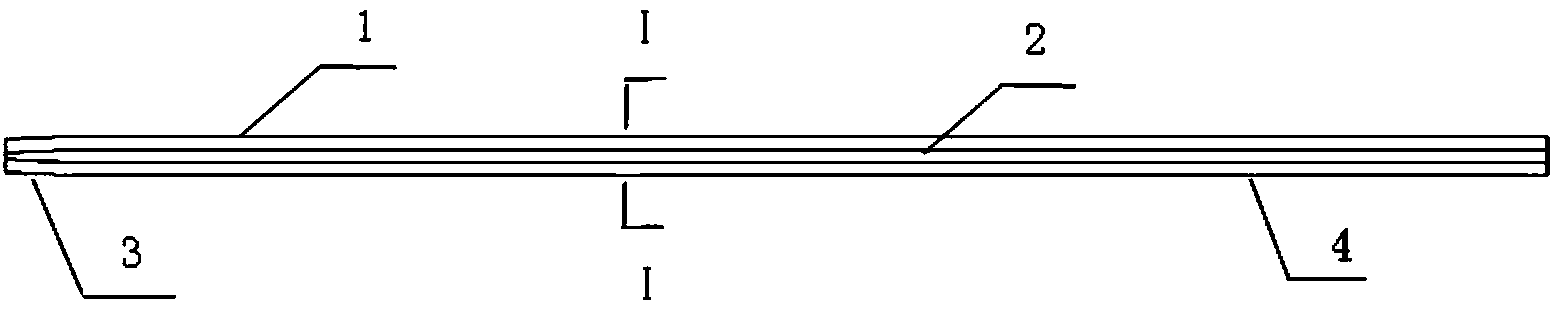

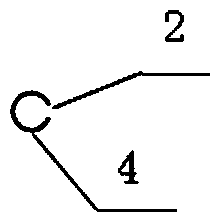

[0013] The anchor cable support structure capable of bearing transverse shearing force of the present invention, its preferred specific embodiment is:

[0014] After drilling on the surrounding rock, ream the part near the outer end of the hole, install a slotted steel pipe at the reamed part, and install a resin end anchor cable in the inside of the hole and in the slotted steel pipe.

[0015] The slit steel pipe is fully slit along the longitudinal direction.

[0016] A necking is provided at the head end of the slotted steel pipe.

[0017] The slotted steel pipe is made of 16Mn steel, the outer diameter of the tail end is 33mm, the outer diameter of the head end is 29mm, the length is 1.2-2.5m, the seam width is 12mm, and the wall thickness is 1.5mm.

[0018] The anchor cable anchored at the resin end has a diameter of 21.6mm and a length of 7-10m.

[0019] The outer end of the anchor cable anchored by the resin end is provided with an anchor cable lock and an anchor cabl...

specific Embodiment

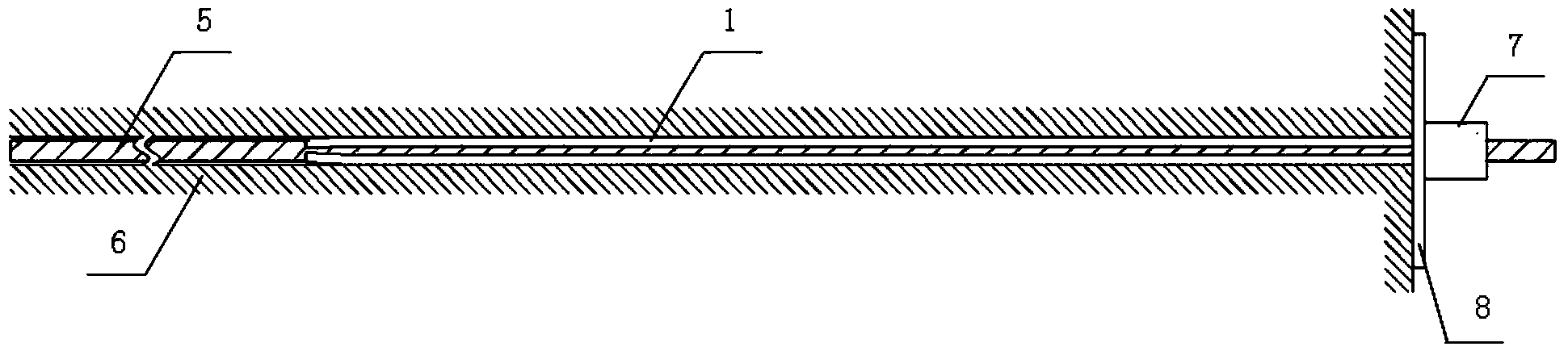

[0025] Such as figure 2 As shown, after the excavation of the coal mine roadway, the roof of the roadway is now used as the support object, and the roof is supported by using the present invention and its support method instead of the conventional anchor cable. Firstly, the slotted steel pipe is installed, and then the resin end anchoring anchor cable is installed. .

[0026] Install slotted steel pipe:

[0027] Ordinary single rock bolter with hollow hexagonal extended drill pipe and φ28mm double-wing drill bit is used for drilling, and φ32mm double-wing drill bit is used for reaming. First, use a φ28 double-wing drill bit to drill a hole. The drilling depth is 7-10m. This length is the length of the anchor cable at the end of the resin to be installed. In order to ensure the accuracy of the hole depth, you can mark the end hole with white or yellow paint on the starting drill pipe. Location. When using a φ32mm double-wing drill bit for reaming, the reaming depth is the l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Seam width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com