A single-sided bolt fastener in a reversed form

A technology of unilateral bolts and deformed parts, which is applied in the direction of connecting components, pins, mechanical equipment, etc., can solve the problems that bolts and nuts can not be used to connect fastening methods, the mechanical properties of bolt rods weaken, and cannot be operated on both sides, etc., to achieve easy The effect of simple and fast implementation and installation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

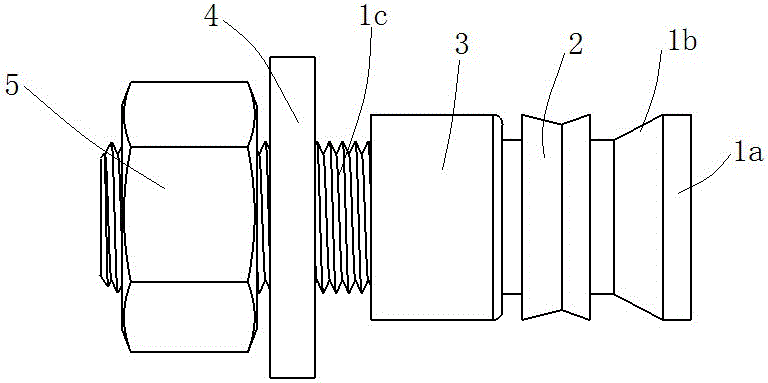

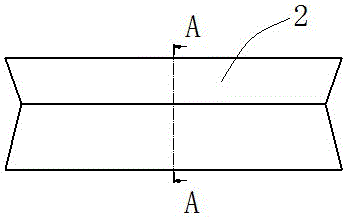

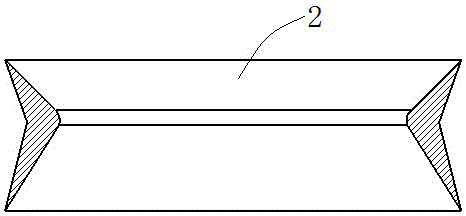

[0020] Embodiment 1: The present invention is composed of a bolt 1 , a turning deformation member 2 , a jacking sleeve 3 , a washer 4 and a nut 5 . A conical surface 1b transitions between the bolt head 1a and the bolt shank 1c, the tail of the bolt shank 1c is provided with a thread, and the overturning deformation member 2 is an annular part with a certain plastic deformation ability. The structure of the inversion element 2 is described in text with reference to FIG. 2 .

[0021] Installation method:

[0022] 1. Before installation, put the overturning deformation part 2, the jacking sleeve 3, and the gasket 4 into the bolt rod 1c in sequence, and then screw the nut 5 at the end of the bolt rod 1c as a whole device;

[0023] 2. When installing, first insert one side of the bolt head 1a into the installation hole 8b, and then start to tighten the nut 5. After reaching a certain pre-tightening force, the unilateral connection and fastening of the structural parts can be real...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com