Needle Plate Insertion Groove Detecting Device in Flat Knitting Machine

A flat knitting machine and detection device technology, which is applied in the field of knitting machinery, can solve the problems that insert pieces cannot be inserted quickly, affect the service life of the flat knitting machine, and deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

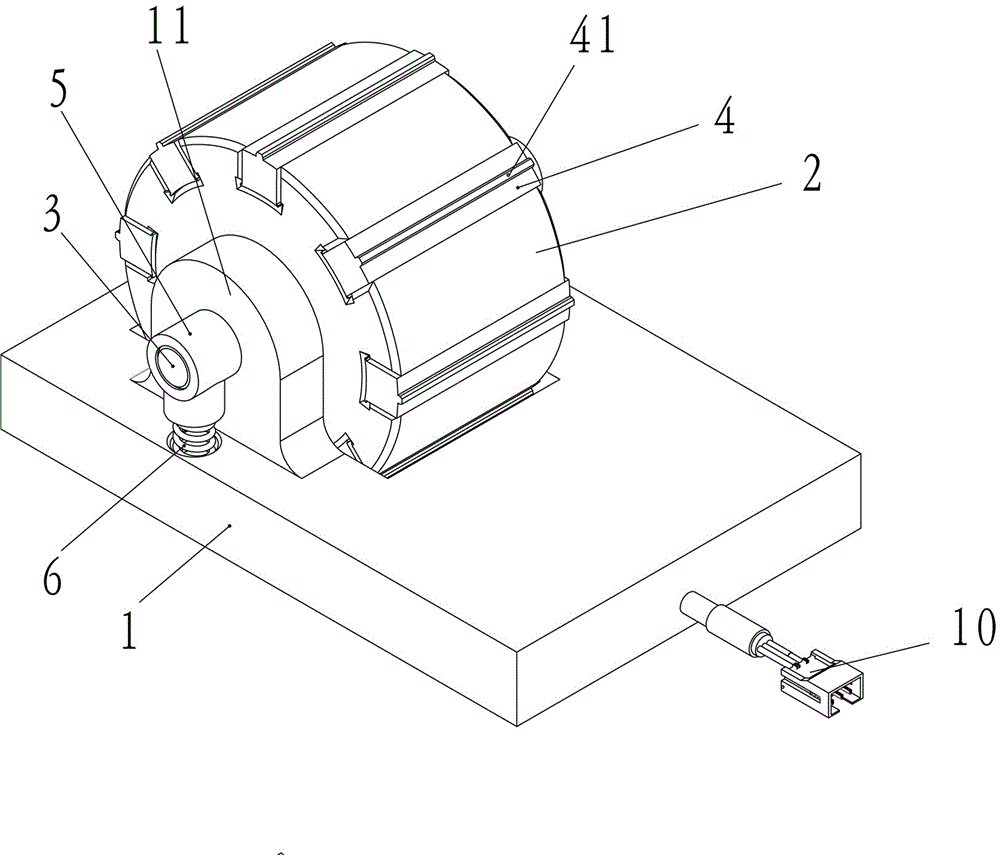

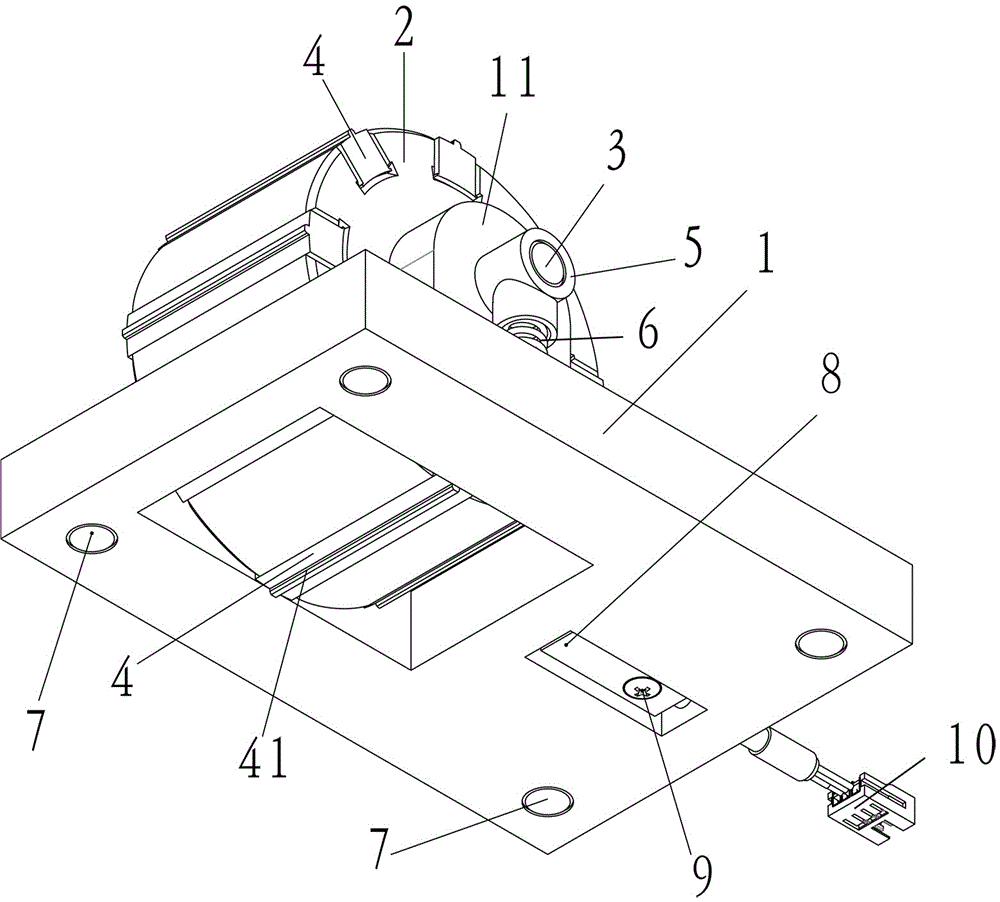

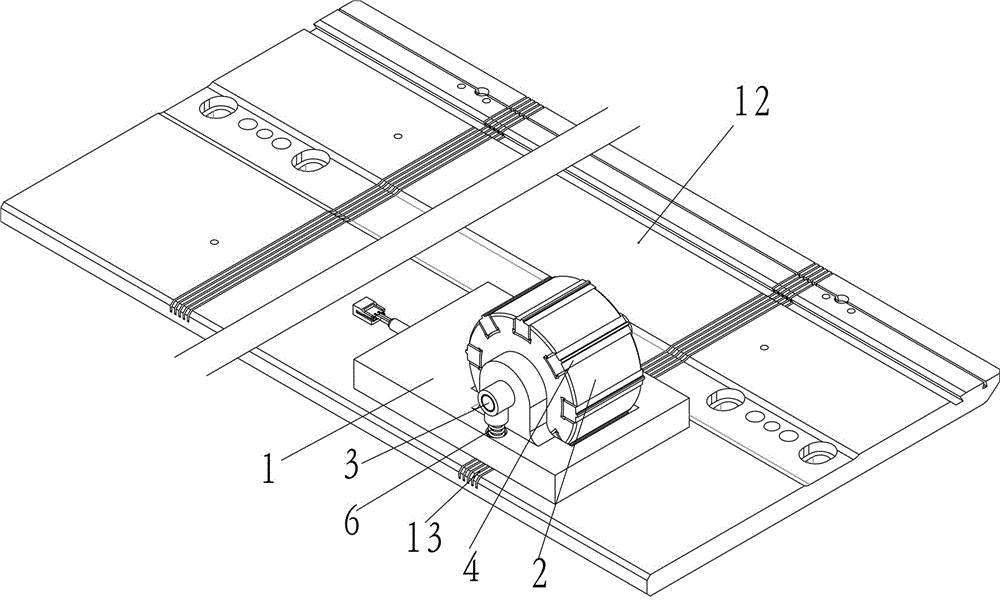

[0011] See attached picture. This embodiment includes a base 1, a runner 2, a runner shaft 3, a detection block 4, a limit block 5 and a spring 6; the base 1 has a rectangular opening in the middle, and a runner fixing block on both sides of the rectangular opening 11. The runner fixing block 11 has a circular fixing hole; the base 1 also has two spring fixing holes, which are respectively located on the outside of the two runner fixing blocks 11; the runner 2 has several rectangular chute , the rectangular chute is distributed on the circumferential surface of the runner 2; the detection block 4 is a rectangular block structure with a detection piece 41 on the upper surface; the detection block 4 is installed in the rectangular chute of the runner 2; The runner 2 is sleeved on the runner shaft 3, and the bottom of the runner 2 passes through the rectangular opening of the base 1; the two ends of the runner shaft 3 respectively pass through the circular fixing holes on the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com