Copper tape brushing and cleaning automatic regulating device

An automatic adjustment device and copper strip technology, applied in the direction of grinding machines, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of radial runout and deflection of wire brushes, and achieve good sliding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

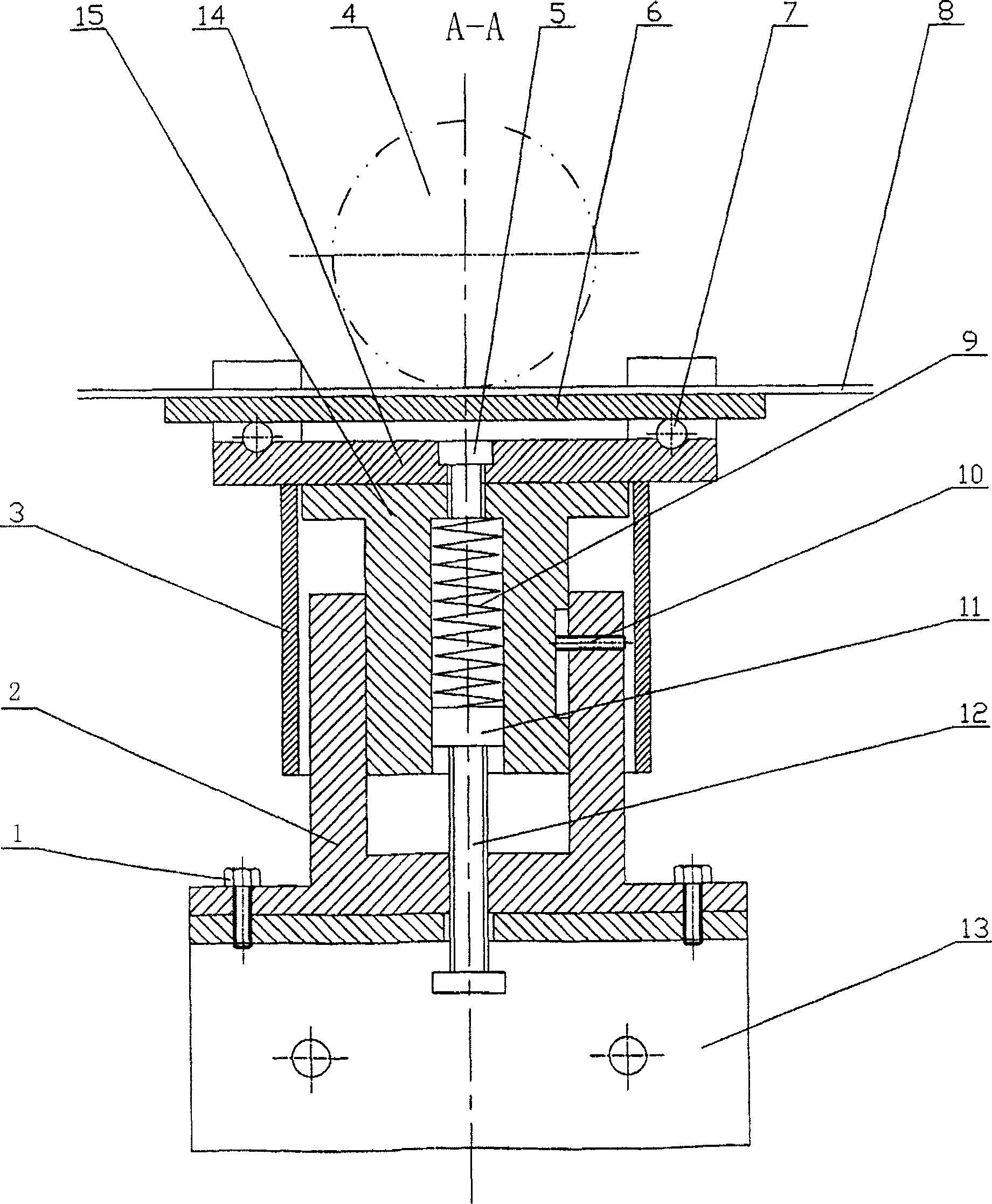

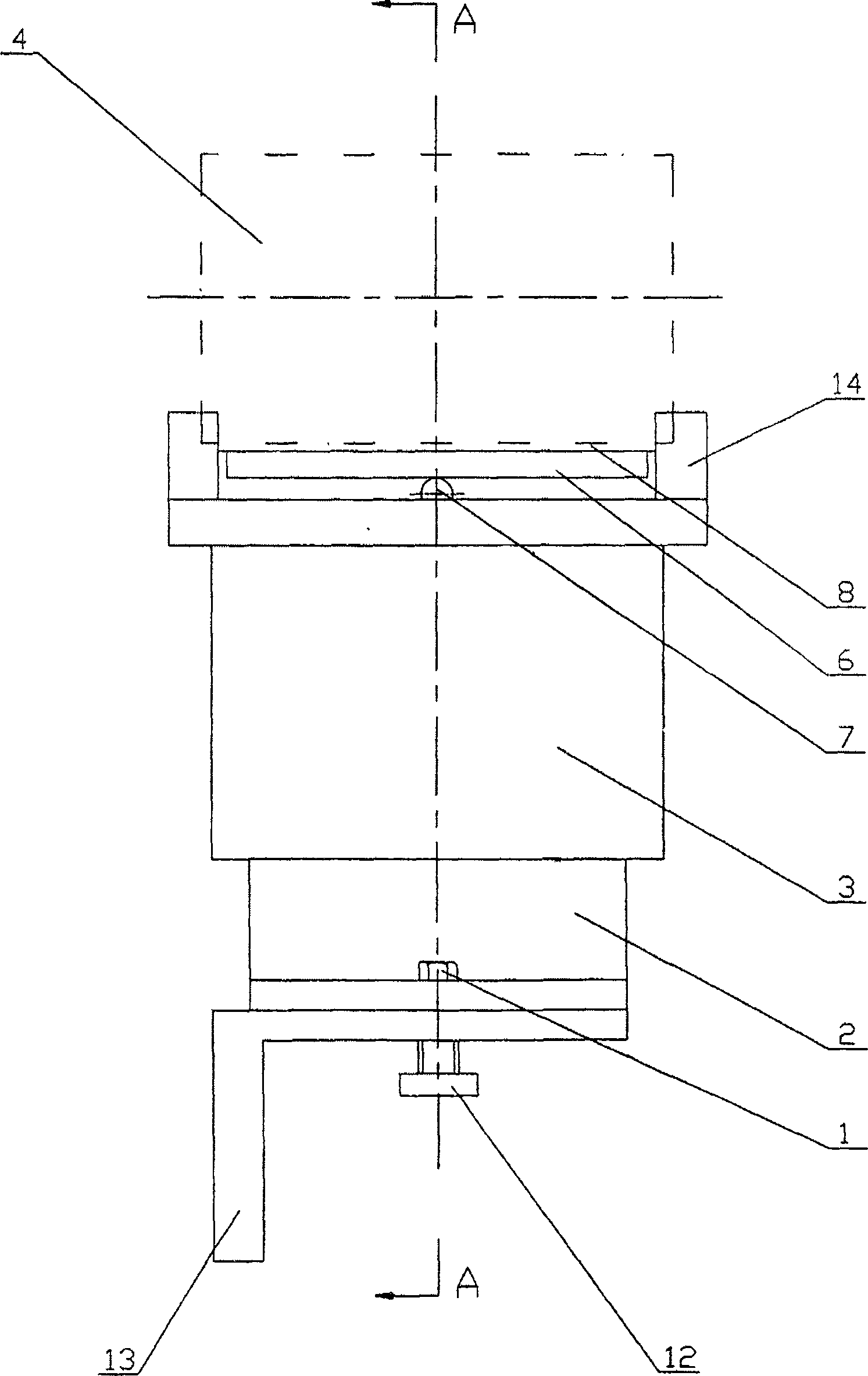

[0023] Such as Figure 1-2 As shown, the sliding seat 2 is fastened on the base bracket 13 by the screw 1, a sliding post 15 is arranged inside the sliding seat 2, a guide groove is arranged on the sliding post 15, and a limit screw 10 is installed between the guiding groove and the sliding seat 2; A spring 9 is installed inside the sliding column 15, and the spring 9 inside the sliding column 15 is combined with the adjusting screw 12 on the slide seat 2 through the spring support pad 11; the top of the sliding column 15 is connected with a bracket 14 through an inner screw 5, and A supporting plate 6 is arranged above the frame 14, and two steel balls 7 are arranged on the same center line between the bracket 14 and the supporting plate 6 as pads; It forms a semi-closed state with the slider 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com