A fiber ring curing pretreatment equipment

An optical fiber ring and pretreatment technology, which is used in instruments, measuring devices, Sagnac effect gyroscopes, etc., can solve the problems of uneven distribution of the ring glue in the ring, affecting the yield of the ring, and reduce the unstable rotation. performance, solve the inability to adjust, and increase the effect of programmable control functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

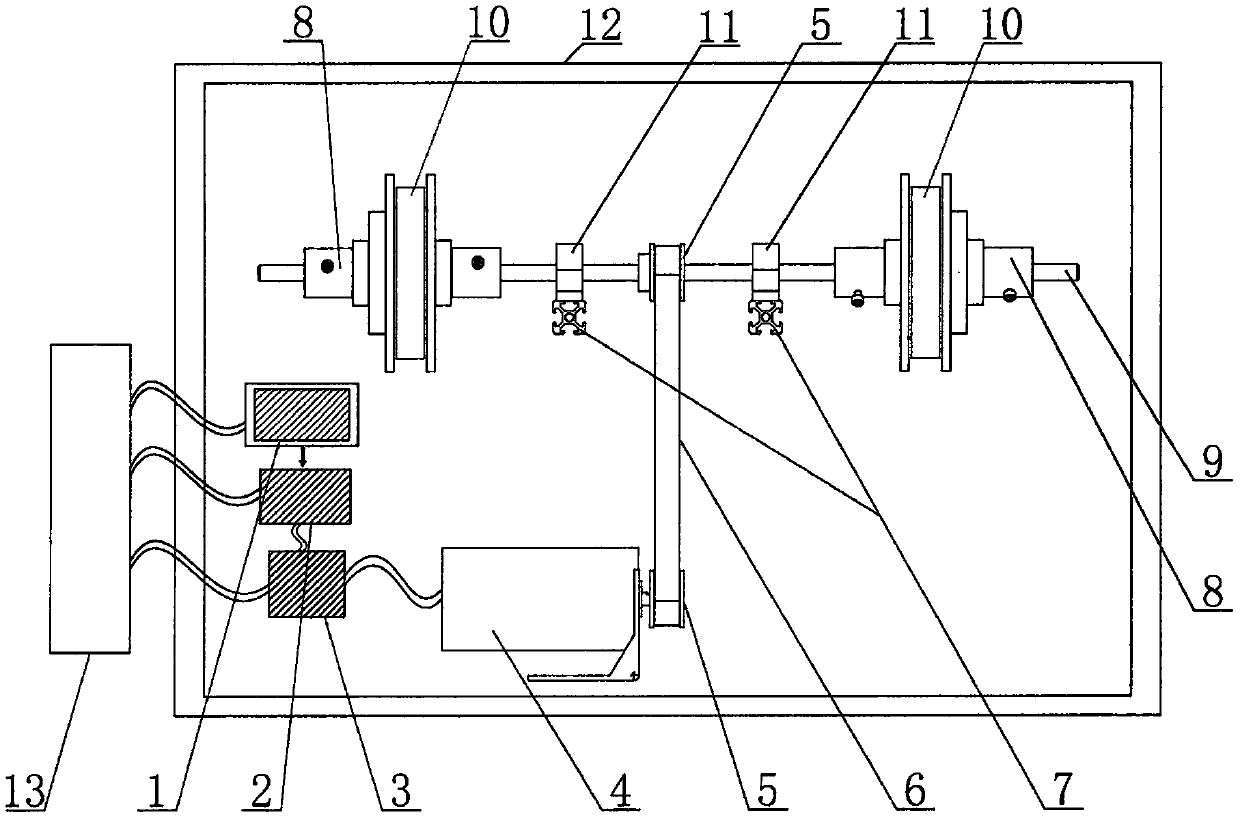

[0021] The structure of the optical fiber ring curing pretreatment equipment is as follows: figure 1 shown. The frame 7 and the housing 12 are used as the support of the whole device to install and fix other components. The motor 4 is installed on the bottom of the frame 7 and its front, rear, left, and right positions are adjustable. Two synchronous wheels 5 are respectively connected with the motor 4 and the rotating shaft 9. The synchronous belt 6 is connected with the two synchronous wheels 5 to realize the synchronous rotation of the motor 4 and the rotating shaft 9. , the motor 4 can move back and forth to adjust the tightness of the synchronous belt 6 installation. The rotating shaft 9 is supported by bearing blocks 11 at a certain distance, and the bearing blocks 11 are installed above the frame 7. The two ends of the rotating shaft 9 protrude in an open form, and two tooling fixtures 8 can be installed in a symmetrical form on both sides of the rotating shaft. An op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com