A winding core that allows lithium-ion battery separators to breathe freely during storage

A lithium-ion battery and winding core technology, which is applied to battery pack parts, circuits, electrical components, etc., can solve problems such as rough surface of the winding core, damage to the performance of the diaphragm, and insufficient air in the micropores of the diaphragm, etc., to ensure The effect of flatness and consistency, elimination of radial runout, and appropriate strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

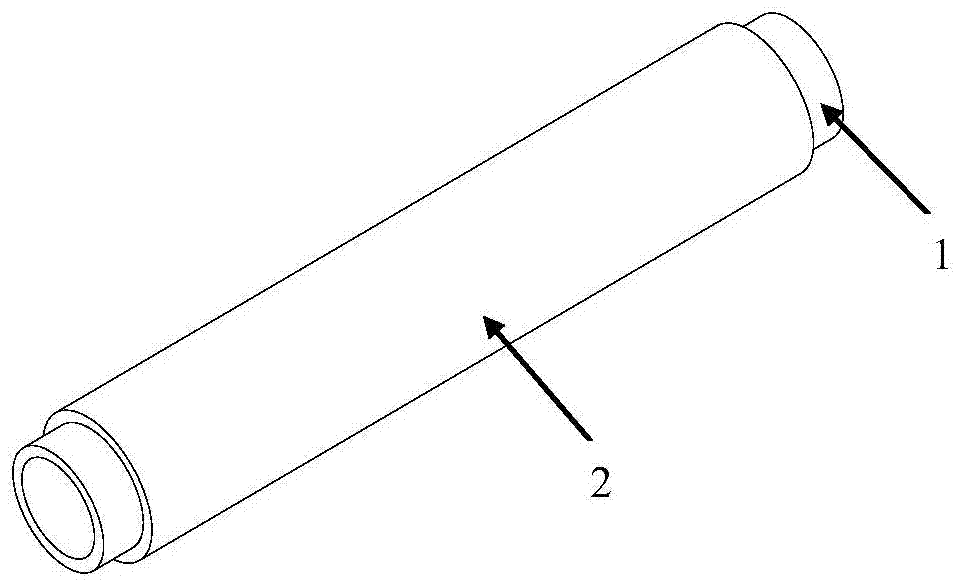

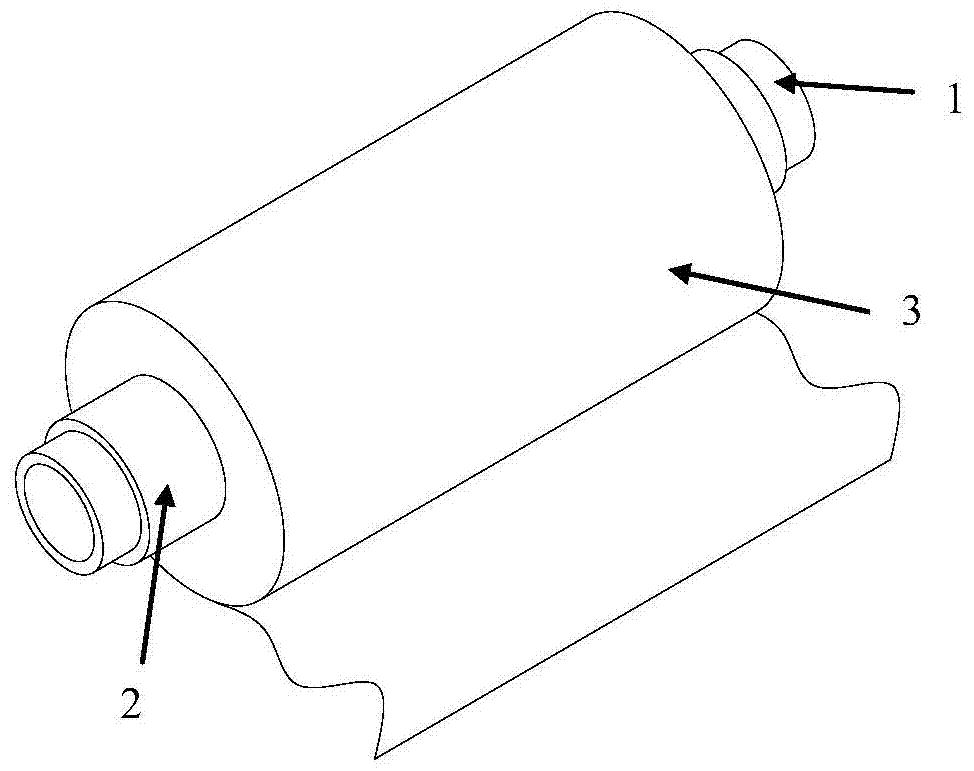

[0018] Such as figure 1 and figure 2 As shown, the present invention provides a winding core for lithium-ion battery separators to breathe freely during storage, including a cylindrical hard winding core 1, and the side wall of the cylindrical hard winding core 1 is covered with a A long cylindrical air-permeable cushion layer 2 made of microporous material, on which the lithium-ion battery diaphragm 3 can be wound when in use.

[0019] On the basis of the above technical solutions, the present invention can be further improved as follows.

[0020] Further, the microporous material is polyurethane microporous elastomer material.

[0021] Further, the polyurethane microporous elastomer material is MDI type or TDI...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com