Automatic adjusting and cooling device for brushing copper belt

A cooling device and self-adjusting technology, applied in cleaning methods and utensils, cleaning methods using tools, chemical instruments and methods, etc., can solve the problem that the wire brush cannot be very accurate, the friction force is large, and the copper strip friction cannot be overcome. heat and other problems, to reduce the probability of oxidation, eliminate friction heat, and achieve the effect of bright surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

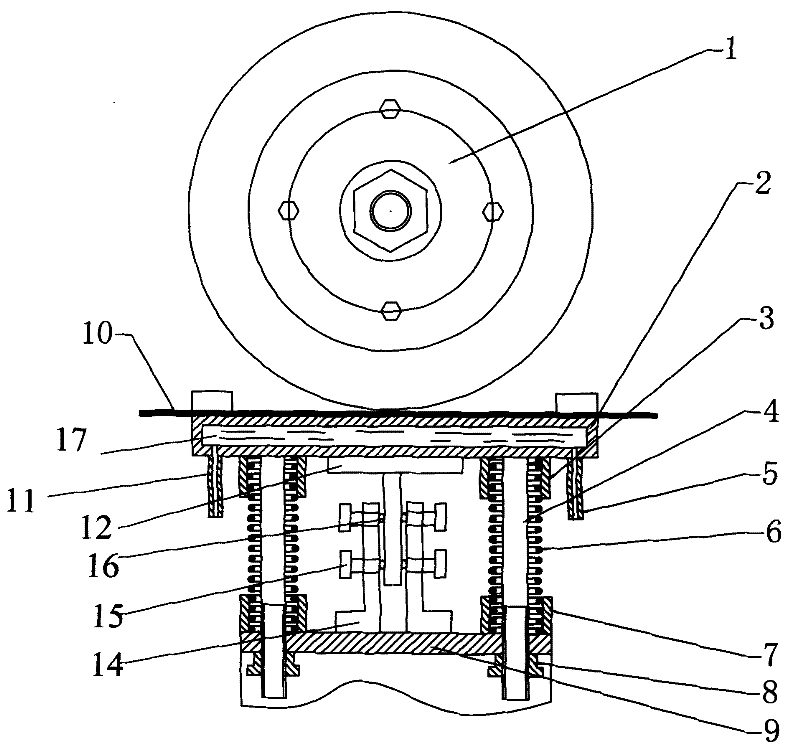

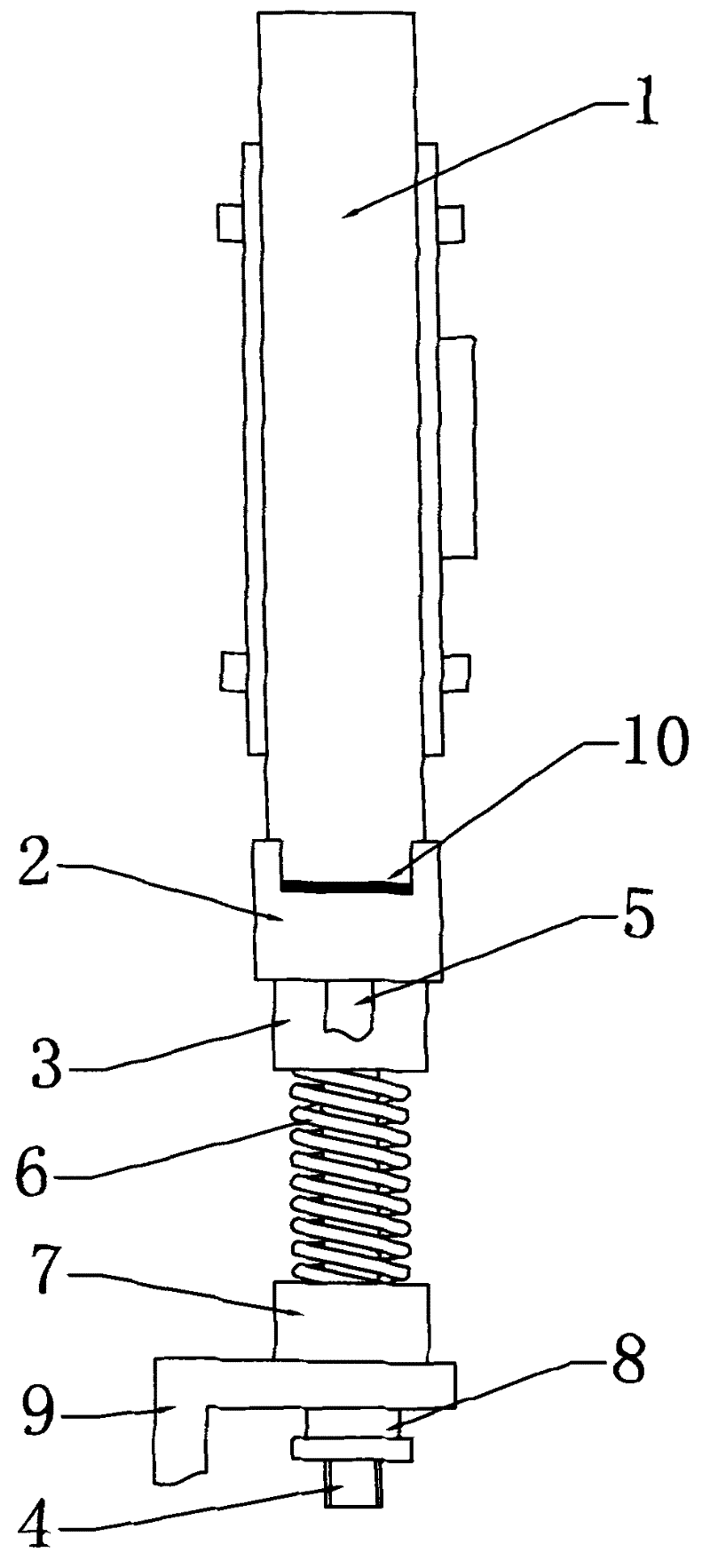

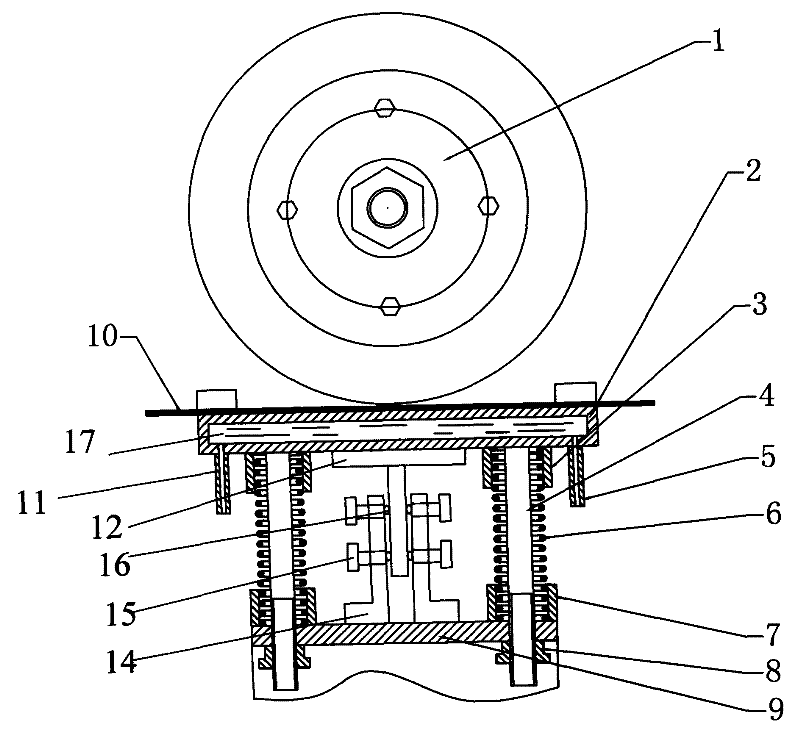

[0022] Such as Figures 1 to 2 As shown, the copper strip brushing automatic adjustment cooling device includes a wire brush 1 and a bracket 9, and a limit guide cooling device for placing the copper strip 10 and an adjustment device for supporting the limit guide cooling device, the limit guide cooling device It is arranged under the wire brush 1, and the adjustment device is symmetrically arranged on both sides of the limit guide cooling device. The limit guide cooling device includes a body 2, a water inlet pipe 5 and a water outlet pipe 11. The inside of the body 2 is provided with a cavity 17 for containing cooling water. 17 connected. The adjustment device includes a guide rod 4 and a spring 6. One end of the guide rod 4 is fixed at the lower end of the limit guide cooling device, and is arranged inside the spring 6, and is matched with the bracket 9. The spring 6 is fixed at the lower end of the limit guide cooling plate. It also includes an upper steel sleeve 3 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com