High-speed direct-driven machine tool fourth shaft

A direct drive, machine tool technology, used in metal processing machinery parts, large fixed members, metal processing equipment, etc., can solve problems such as difficult waterproof sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

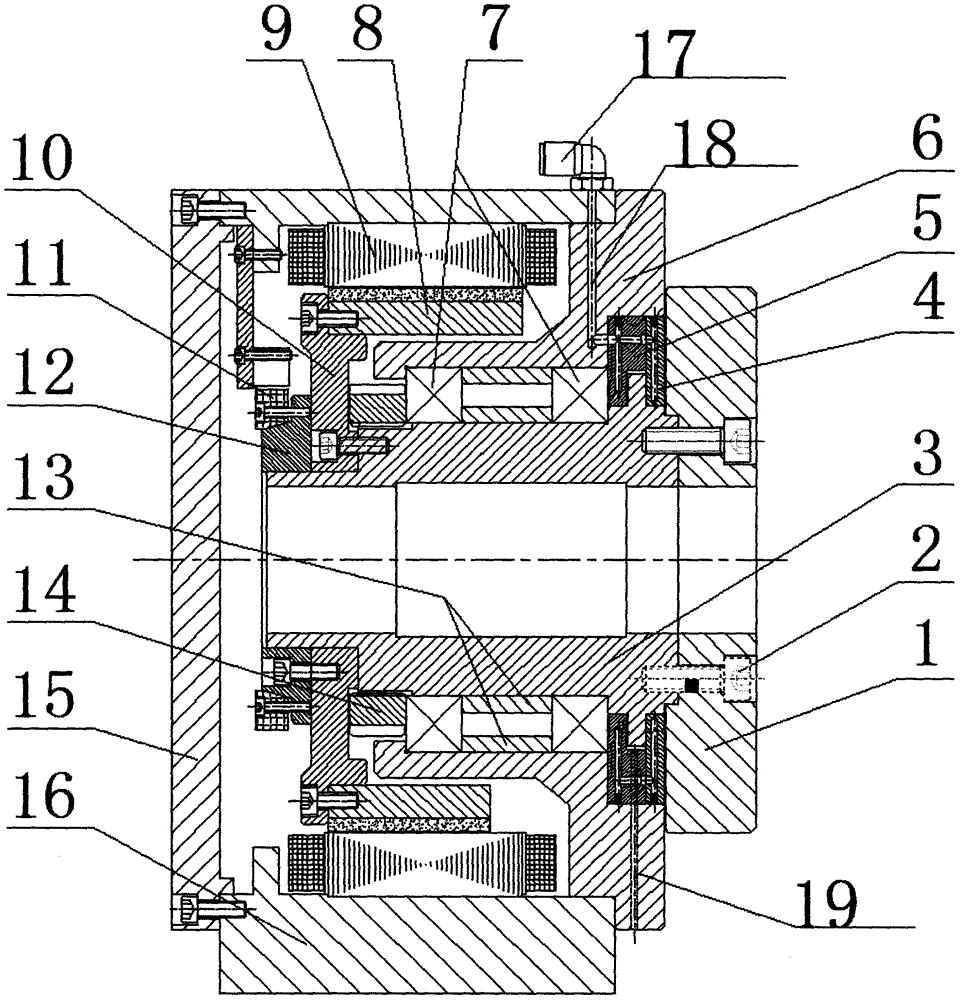

[0027] refer to figure 1 , an example of the present invention, a fourth axis of a high-speed direct drive machine tool, mainly includes:

[0028] The body 16 is equipped with a motor stator 9, a motor rotor 8, a bearing seat 6, a bearing 7 installed on the bearing seat 6, and a rotary shaft 3 from the outside to the inside, and the rotary shaft 3 is installed in the In the bearing 7, the lower end of the rotary shaft 3 is locked to the inner ring of the bearing 7 through the lock nut 14, and the motor rotor 8 is connected to the rotary shaft 3 through the rotor connecting seat 10;

[0029] Rear air floatation plate 5, described rear air floatat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com