An automatic compensation device for the gap of the C-arm of a medical mobile X-ray machine

An automatic compensation and X-ray machine technology, which is applied in the field of medical equipment, can solve the problems of C-arm scanning accuracy not meeting the requirements, too high tolerance requirements for track section dimensions, and section dimensions greater than the upper deviation, etc., achieving remarkable working results , light weight, and the effect of eliminating gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

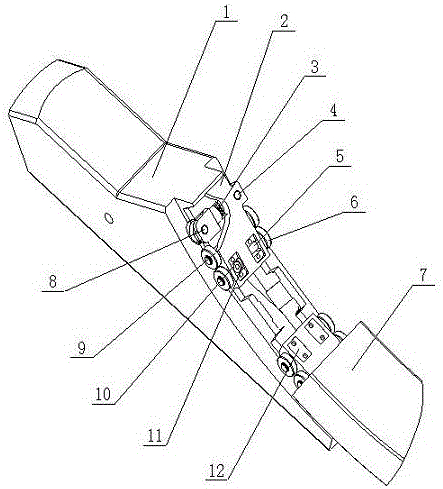

[0007] Referring to the accompanying drawings, its structure consists of C-arm support (1), guide wheel support (2), lateral automatic compensation spring (3), lateral fixed guide wheel assembly (4), axial floating guide wheel shaft (5), Axial floating guide wheel assembly (6), C-arm (7), lateral floating guide wheel assembly (8), axial fixed guide wheel assembly (9), axial automatic compensation spring (10), spring seat (11 ), a spring pressure plate (12), characterized in that: the guide wheel bracket (2) is fixed on the C-shaped arm bracket (1), and one side of the guide wheel bracket (2) is assembled with a laterally fixed guide wheel assembly (4), Assemble the lateral floating guide wheel assembly (8) on the other side of the guide wheel bracket (2), assemble the lateral automatic compensation spring (3) at the inner end of the lateral floating guide wheel assembly (8), and fix the guide wheel assembly axially (9) Assemble in the middle hole of the guide wheel bracket (2)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com