Indirect measuring method for hypersonic speed wind tunnel turbulence scale

A measurement method, hypersonic technology, applied in the direction of measuring devices, machine/structural component testing, instruments, etc., can solve problems such as hot wires are easy to break, tracer particles have poor followability, and shock waves have a large impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

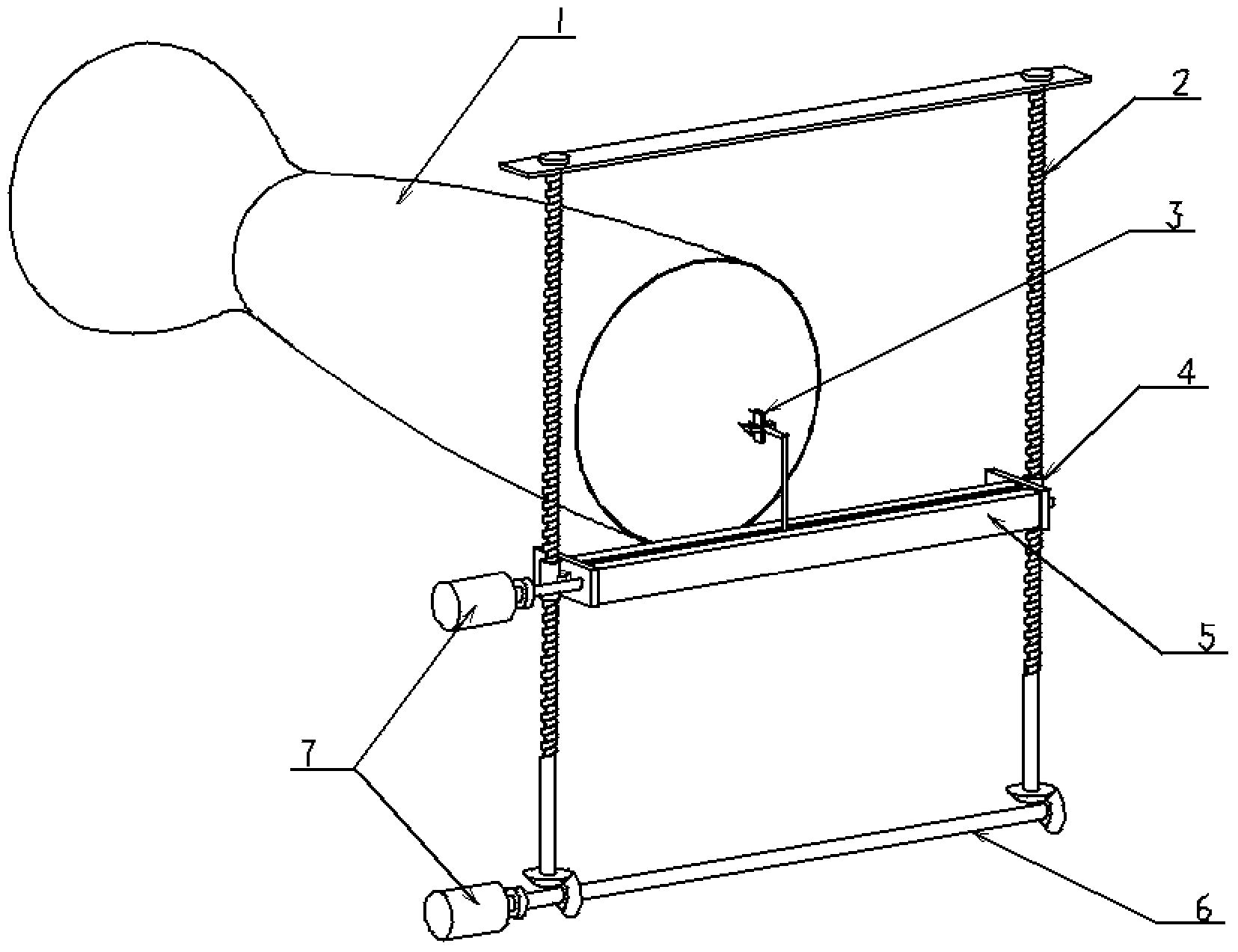

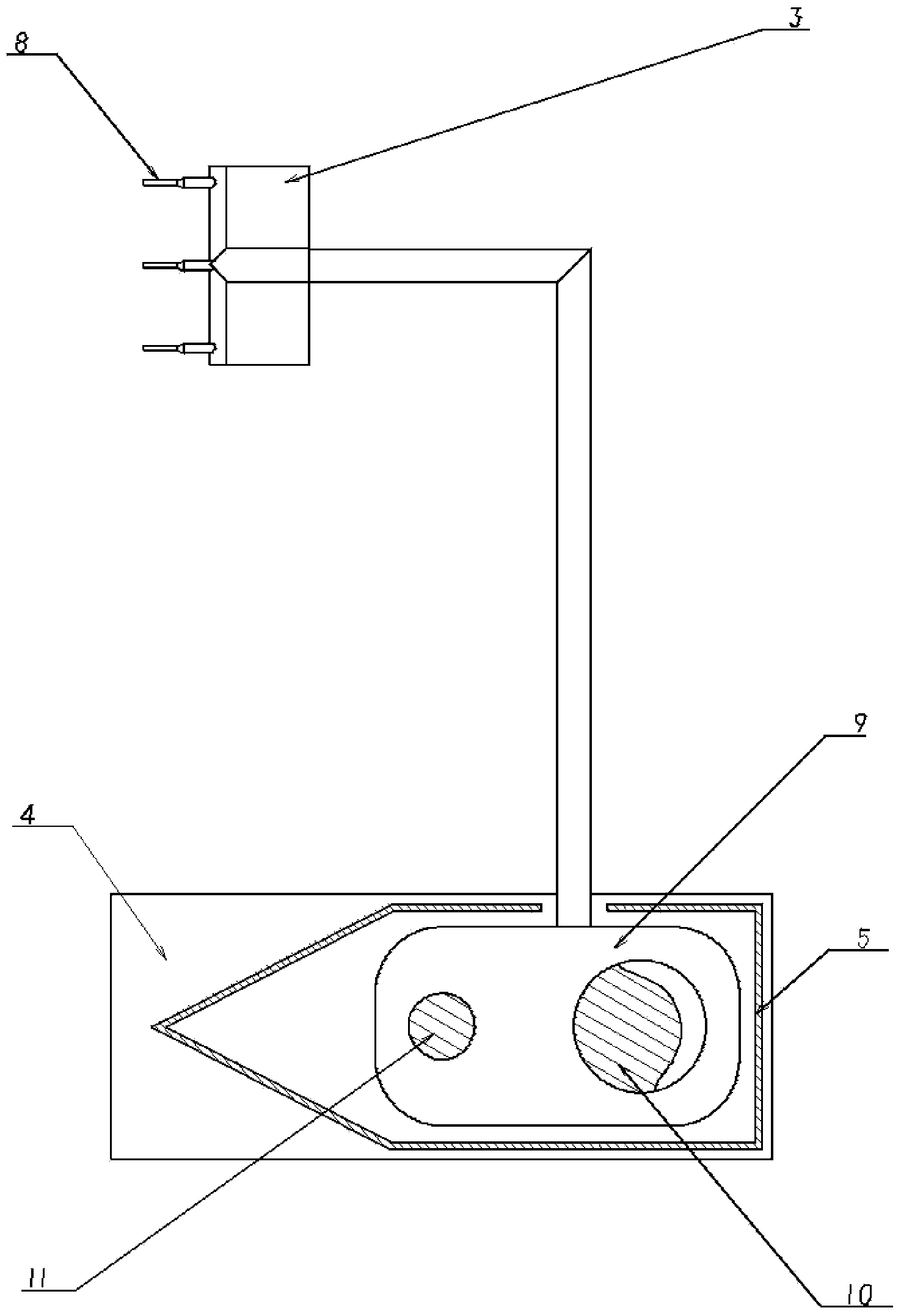

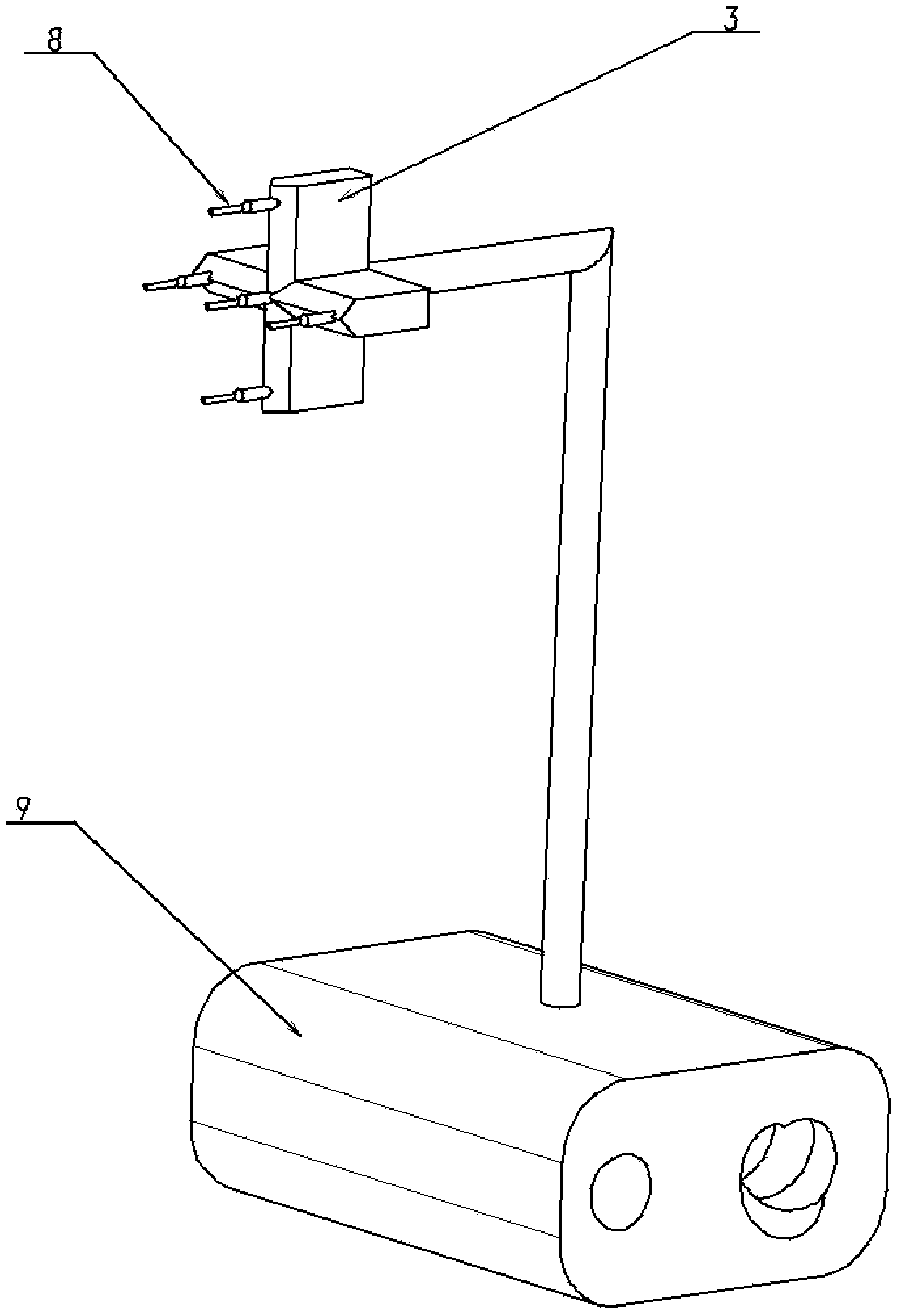

[0068] Embodiment: Indirect measurement method of hypersonic wind tunnel turbulence, the wind tunnel exit section diameter given in this embodiment is 600mm, the distance from the four probes on the upper edge of the probe support to the center probe is 25mm, and the wind tunnel exit The measuring points on the section are distributed at a distance of 25 mm in both the x-axis and y-axis directions. Let the coordinates of the measuring point on the origin be (0,0), move x×25mm toward the x-axis, and mark the measuring point as (x,0); move toward the y-axis y×25mm, and mark the measuring point as (0,y ); if moving to the x-axis and y-axis at the same time, the coordinates of the measuring point are marked as (x, y).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com