In situ observation device and method of pitting forming process

An observation device and in-situ technology, which can be used in measurement devices, instruments, scanning probe microscopy, etc., and can solve the problems of in-situ dynamic observation of topographic features.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

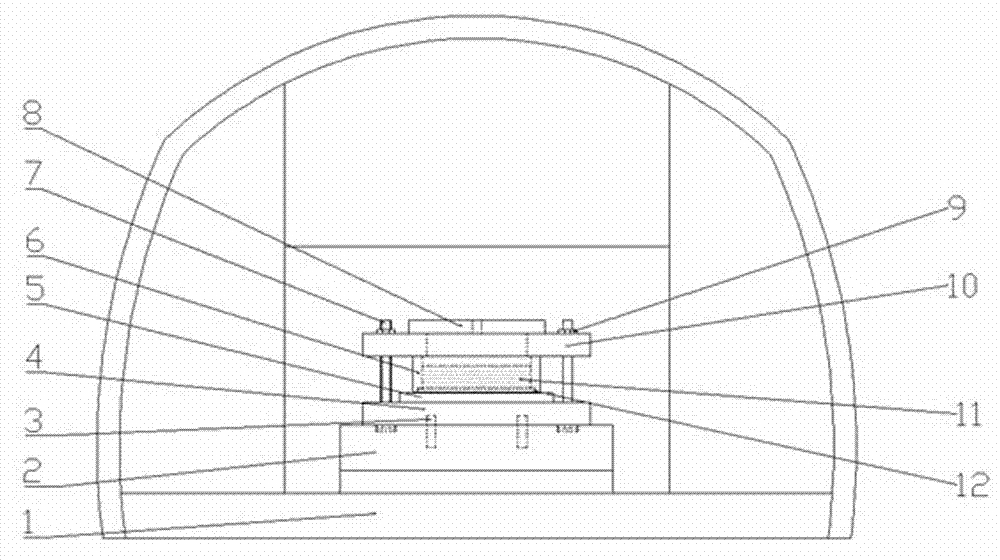

[0023] The above-mentioned atomic force microscope 1 uses the Dimension Edge large sample stage atomic force microscope of Bruker, Germany;

[0024] The sample stage 2 is made of plexiglass with a diameter of 150mm and a thickness of 20mm, with three positioning pin holes;

[0025] The electrolytic cell bottom plate 4, the electrolytic cell cylinder 6, the upper cover plate 8 and the upper panel 10 are all made of organic glass, and the electrolytic cell bottom plate 4 contains three positioning pins 3;

[0026] The compression bolt 7, compression nut 9 and positioning pin 3 are made of stainless steel;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com