Polarizer, substrate structure and display panel

A polarizing plate and substrate technology, applied in optics, optical components, polarizing components, etc., can solve the problems of complex process and weak fixing, and achieve the effect of simplifying the realization process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to solve the problem that the existing electrostatic discharge protection method has a complex process and is not firmly fixed, in the embodiment of the present invention, a polarizer containing a conductive adhesive film is used to derive the static electricity generated by the corresponding substrate, and the conductive adhesive film and the corresponding substrate can be directly used. The grounding piece is connected, so that there is no need to attach additional conductive tape or conductive foam, which simplifies the realization process of electrostatic discharge protection, and there is no problem of loose fixation.

[0023] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

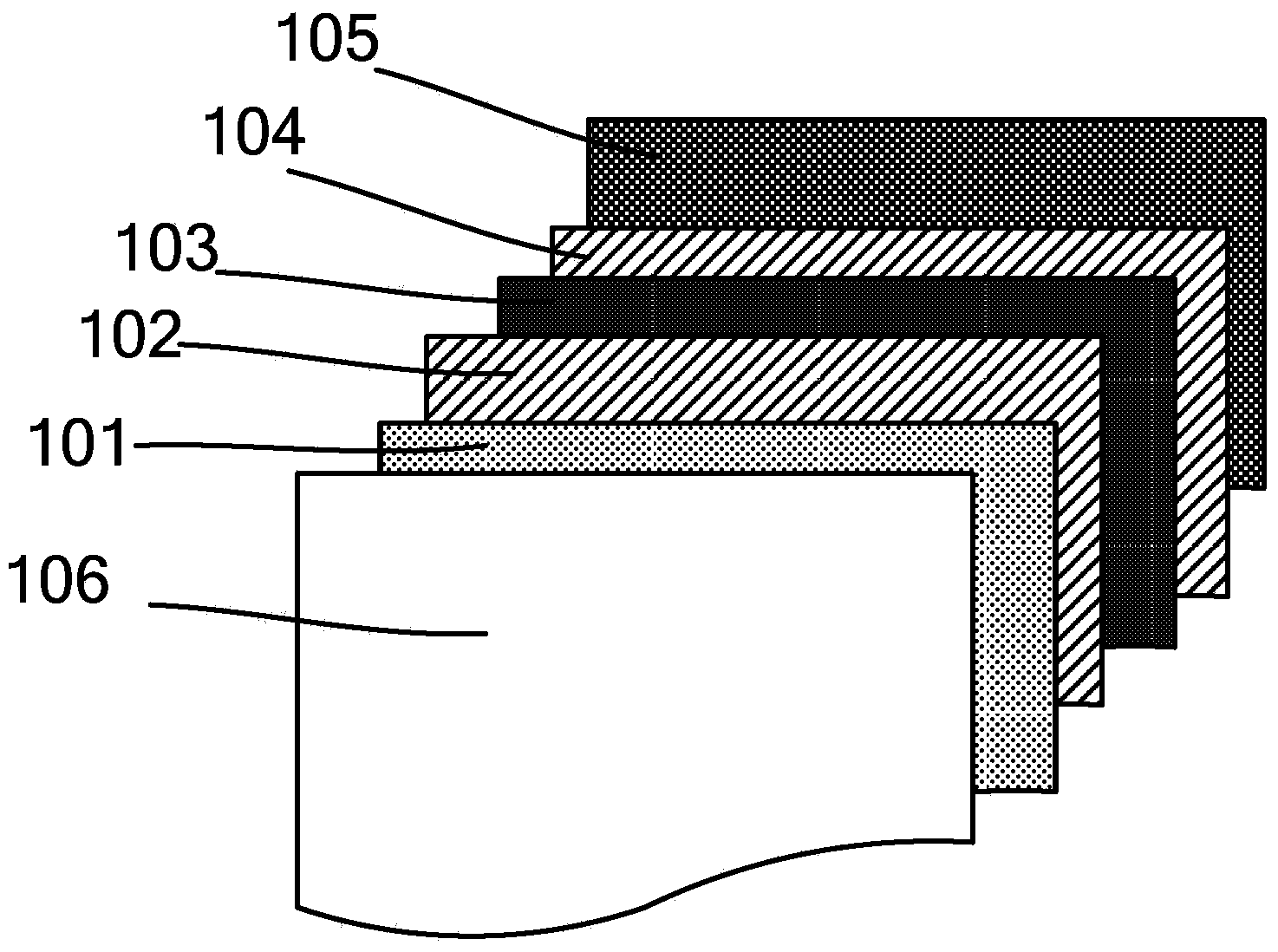

[0024] Please refer to figure 1 , figure 1 It is a schematic diagram of a layered structure of a polarizing plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com