Solid Insulated Ring Main Unit

A solid insulation, ring network cabinet technology, applied in switchgear, grounding device, electrical components and other directions, can solve the problems of operator bumping, inconvenience, increase the space occupied by the shutter, etc., to achieve labor-saving operation and reduce use costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

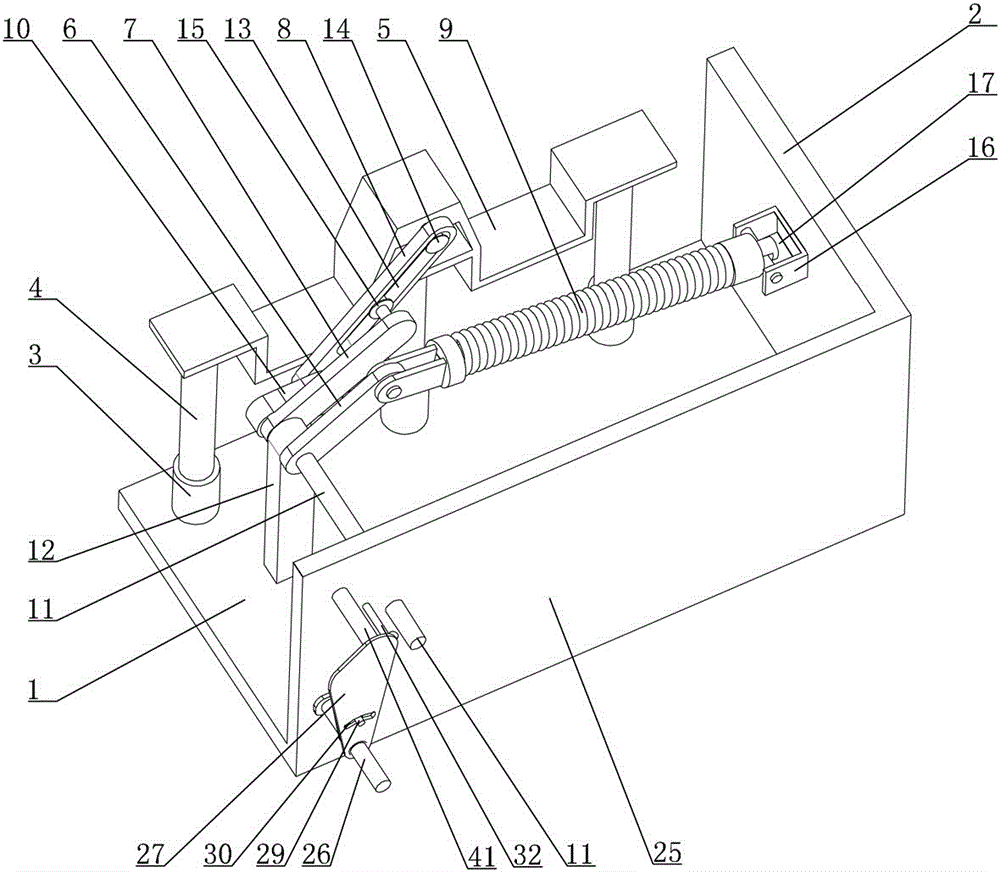

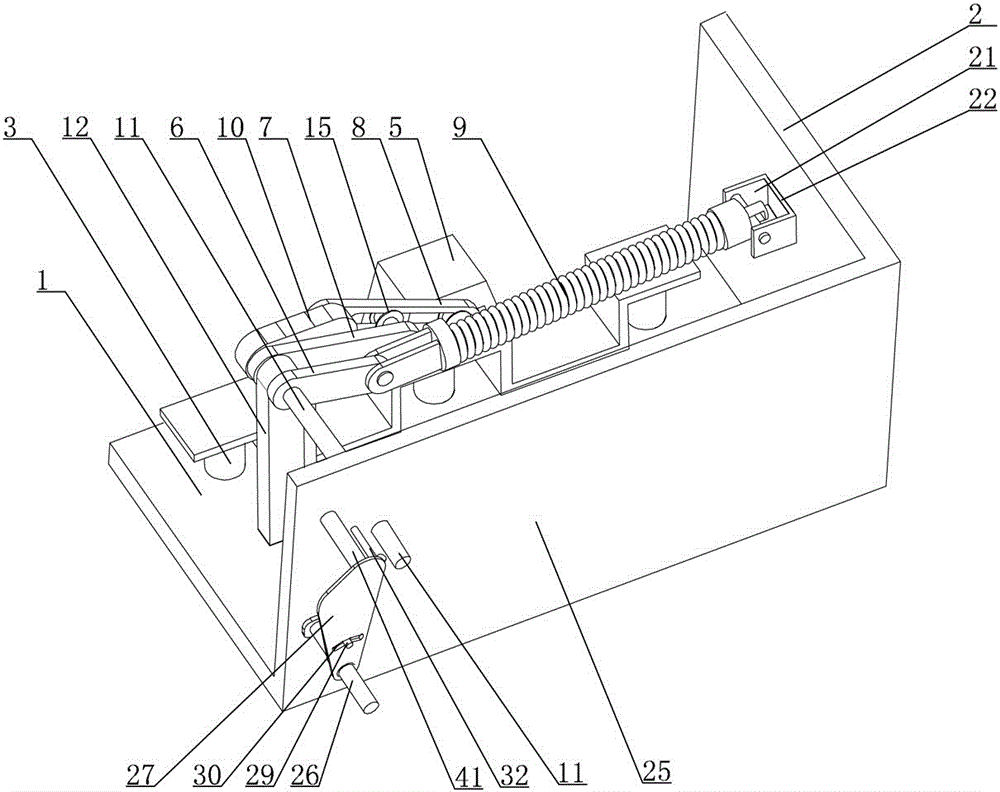

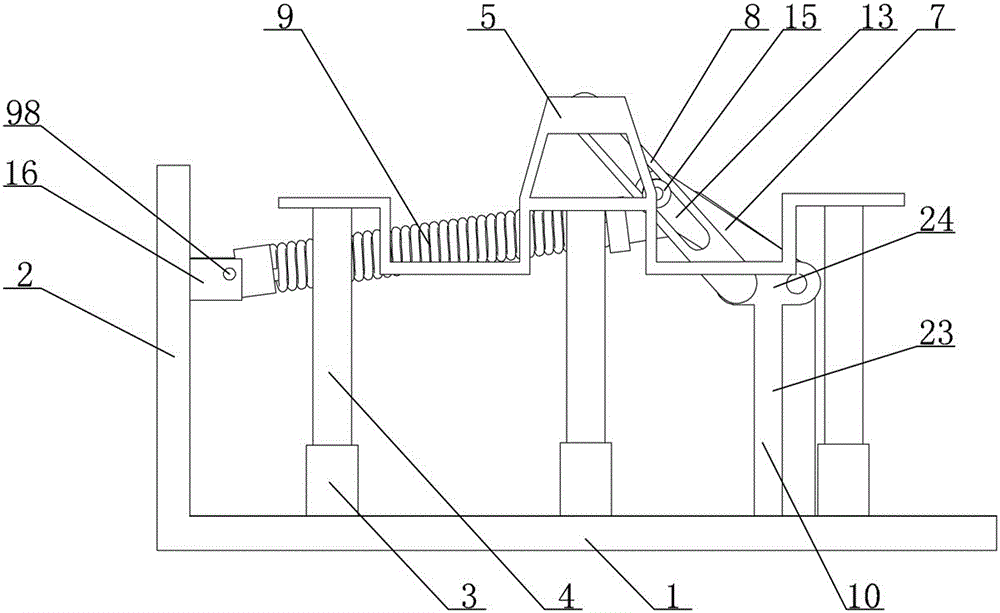

[0027] The present invention will be further elaborated below by means of the accompanying drawings and examples.

[0028] Such as figure 1 , figure 2 and image 3Shown: a solid insulated ring network cabinet, including a cabinet body, the cabinet body includes a bottom plate 1, a top plate, a side plate 2, a front plate 25 and a rear plate, and the side plates include a left side plate and a right side plate. In this embodiment, Said side plate specifically refers to the right side plate. In order to clearly show the structure inside the cabinet, the top panel, rear panel and left panel are removed from the diagram. There is a grounding switch mechanism in the cabinet, and the grounding switch mechanism includes a static contact seat 3, a moving contact 4, a crank arm 6, a crank arm 2 7, a crank arm 3 8 and a return spring assembly 9, and the moving contact 4 is A moving contact fixing seat 5 is provided. The moving contact 4 is inserted into the static contact seat 3 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com