Cross-seat track beam support

A straddle track and seat plate technology, applied in bridges, bridge parts, bridge construction, etc., can solve the problems affecting the operation safety, service life, installation and construction convenience, material performance control, and surface treatment of straddle monorail traffic The requirements for processing precision of parts and parts are high, and the vertical height cannot be adjusted steplessly continuously, so as to achieve the effects of improving safety, reliability, installation and construction, improving convenience, and low tensile function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

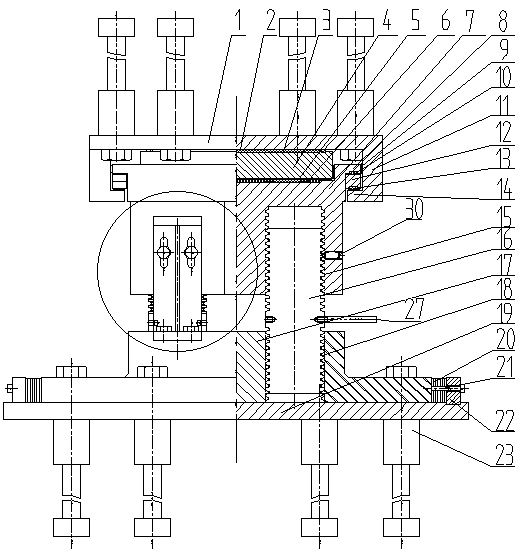

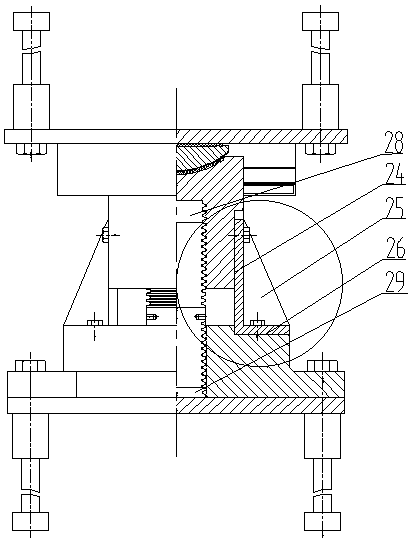

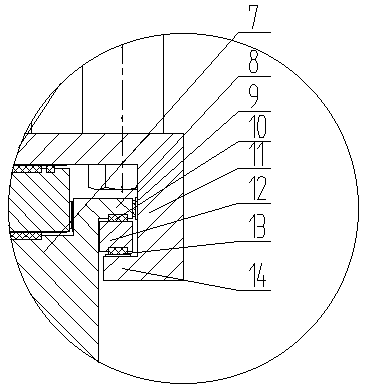

[0065] Such as Figure 7 As shown, the lower part of the lug 8 of the lower seat plate of the pull-out-resistant structure is provided with a concave arc-shaped structure. The surface of the arc structure is covered with a friction plate with a low coefficient of friction and matches with the upward convex arc surface of the rotary slider 12 to form a rotary friction pair of the rotary slider to adapt to the longitudinal rotation of the upper beam.

[0066] The lower plane of the rotating slider 12 of the anti-drawing structure is coated with a friction plate with a low friction coefficient and matched with the stainless steel sliding plate coated on the upper surface of the upper seat plate tensile plate 14 to form a plane friction pair of the rotating slider. To accommodate the longitudinal displacement of the upper beam body.

Embodiment 2

[0068] Such as Figure 8As shown, the lower part of the lug 8 of the lower seat plate of the pullout-resistant structure is provided with a convex arc-shaped structure. The surface of the arc structure is covered with a friction plate with a low coefficient of friction and matches the upper concave arc surface of the rotary slider 12 to form a rotary friction pair of the rotary slider to adapt to the longitudinal rotation of the upper beam.

[0069] The lower plane of the rotating slider 12 of the anti-drawing structure is coated with a friction plate with a low friction coefficient and matched with the stainless steel sliding plate coated on the upper surface of the upper seat plate tensile plate 14 to form a plane friction pair of the rotating slider. To accommodate the longitudinal displacement of the upper beam body.

Embodiment 3

[0071] Such as Figure 9 As shown, the lower part of the rotating slider 12 of the anti-pullout structure is provided with a convex arc-shaped structure. The surface of the arc-shaped structure is covered with a friction plate with a low coefficient of friction and matches the upper concave arc surface of the upper seat plate tensile plate 14 to form a rotating friction pair of the rotating slider to adapt to the longitudinal rotation of the upper beam.

[0072] The lower surface of the lug 8 of the lower seat plate of the anti-drawing structure is covered with a friction plate with a low friction coefficient and matches with the stainless steel slide plate coated on the upper surface of the rotating slider 12 to form a plane friction pair of the rotating slider. To accommodate the longitudinal displacement of the upper beam body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com