Self-switching gripper arm structure using handling robot in narrow environment

A handling robot and self-switching technology, applied in the field of handling robots, can solve the problems of high cost, unsuitable for narrow environments, and large space for fixture arm installation, so as to achieve the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

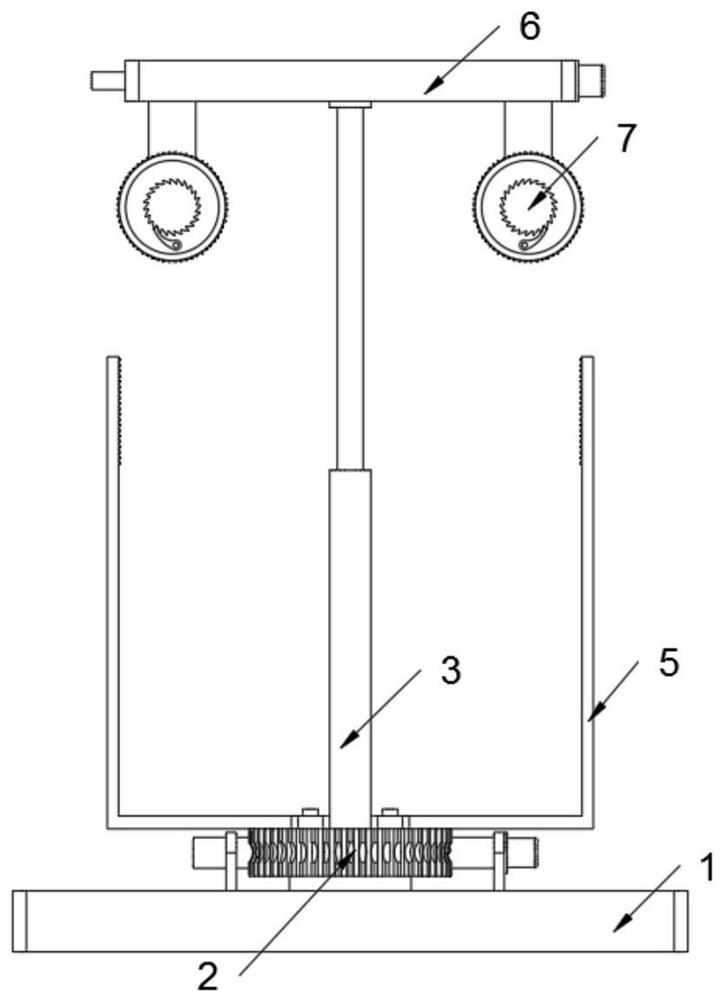

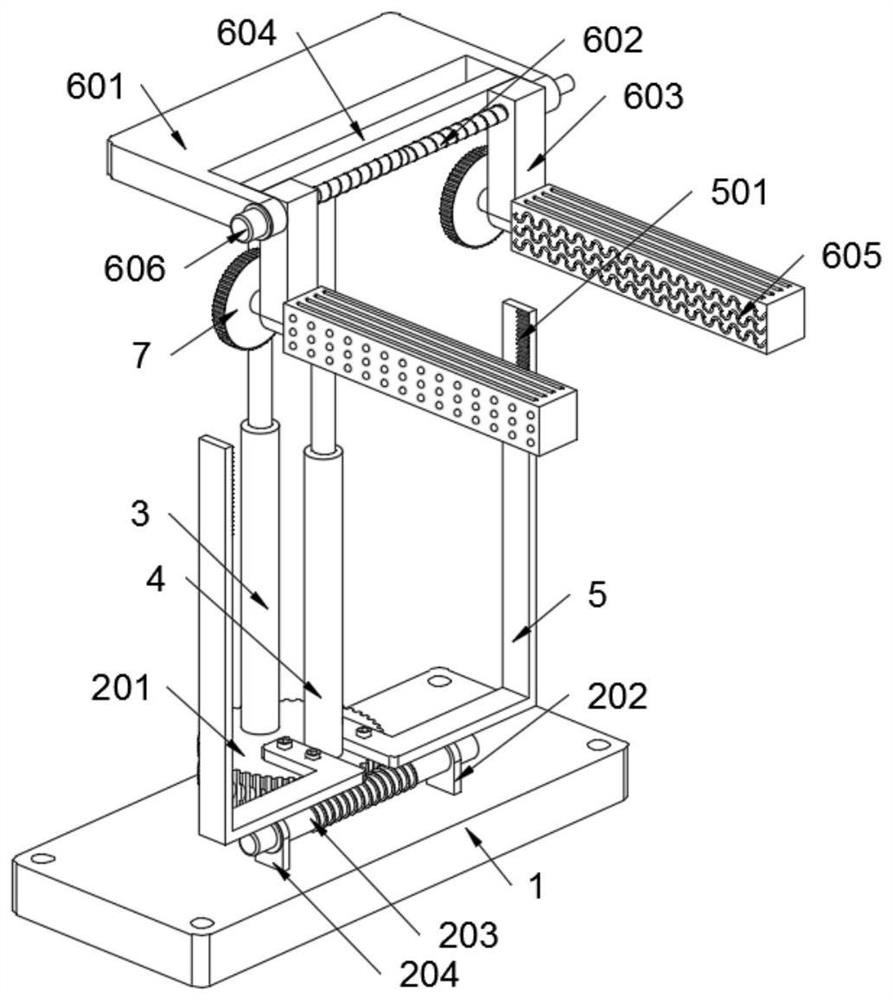

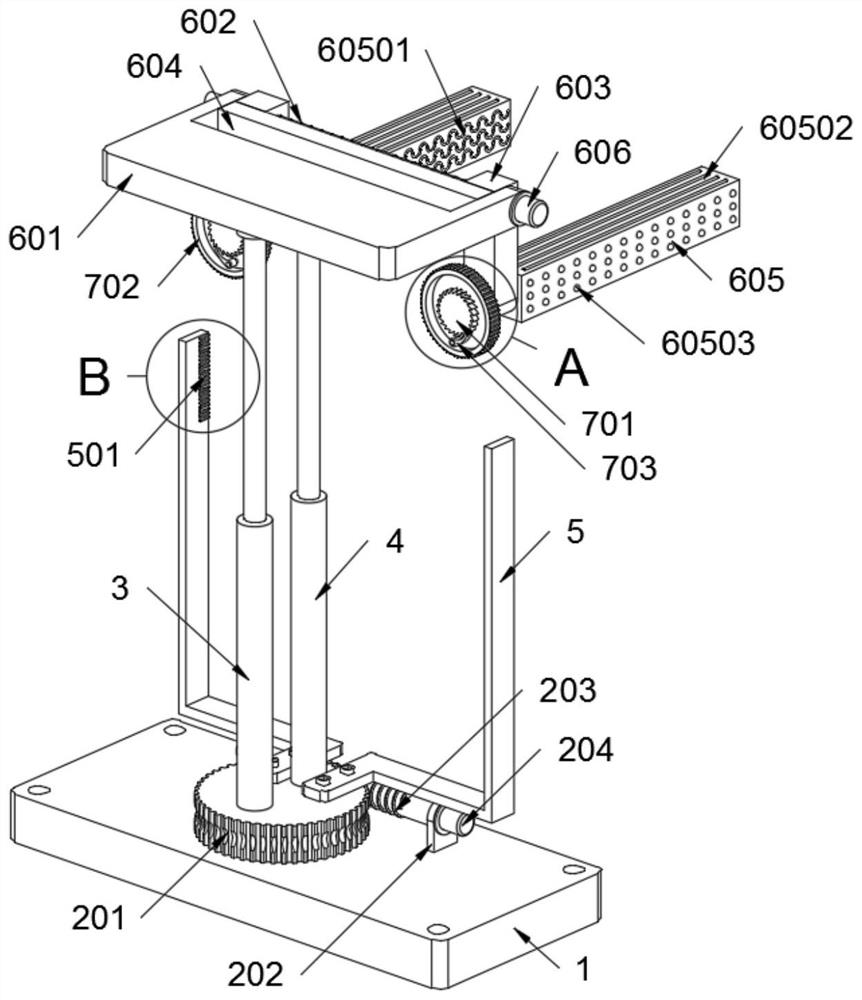

[0031] Such as Figure 1 to Figure 7As shown, the narrow environment of the preferred embodiment of the present invention uses the self-switching clamp arm structure of the handling robot, including a base 1, a rotation adjustment structure 2 is installed on the base 1, and an electric telescopic rod 3 is installed on the rotation adjustment structure 2. Rod 4 and adjusting arm 5. A clamping structure 6 is installed on the head ends of the electric telescopic rod 3 and the telescopic rod 4 , and two driving structures 7 are mounted on the clamping structure 6 . refer to Figure 6 and Figure 7 , the adjusting arm 5 includes a tooth row 501, and there are two adjusting arms 5, and the two adjusting arms 5 are symmetrically fixedly connected to the gear 201, and each adjusting arm 5 is welded with a tooth row 501; when the electric telescopic rod 3 shrinks and drives the driving structure 7 to move downwards, the gear sleeve 702 meshes with the gear row 501, and at this time ...

Embodiment 2

[0033] Such as figure 2 As shown, the rotation adjustment structure 2 includes a gear 201, a rotation connection seat 202, an adjustment rod A203 and a drive motor A204. The gear 201 is rotatably connected to the base 1, and the rotation connection seat 202 is welded on the base 1, and A driving motor A204 is installed. The adjusting rod A203 is rotatably connected to the rotating connection base 202, and the head end of the adjusting rod A203 is connected to the rotating shaft of the driving motor A204. The adjustment rod A203 is provided with helical teeth, and the helical teeth mesh with the gear 201, and the adjustment rod A203 and the gear 201 together form a worm gear structure, thereby realizing the rotation adjustment of the gear 201 and the automatic locking after adjustment.

[0034] Such as figure 2 As shown, the clamping structure 6 includes a main body seat 601, an adjustment rod B602 and a connecting block 603. The bottom surface of the main body seat 601 is ...

Embodiment 3

[0039] Such as image 3 and Figure 4 As shown, the driving structure 7 includes a ratchet gear 701, a gear sleeve 702 and a toggle lever 703. The ratchet gear 701 is welded on the rotating shaft of the clamping arm 605, and a gear sleeve 702 is rotatably connected to the rotating shaft of the clamping arm 605. A toggle lever 703 is installed in the gear sleeve 702, and the toggle lever 703 is meshed with the ratchet gear 701, and the ratchet gear 701, the gear sleeve 702 and the toggle lever 703 together form a ratchet structure, so that the gripping arm 605 can be realized One-way rotation.

[0040] Such as Figure 7 As shown, there is an interference rotational fit between the rotating shaft of the clamping arm 605 and the main body seat 601, and the rotational frictional resistance between the rotating shaft of the clamping arm 605 and the main body seat 601 is greater than that between the gear sleeve 702 and the rotating shaft and The sum of the frictional resistance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com